-

Posts

2,372 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by immiketoo

-

-

8 hours ago, ABHandmade said:

Thanks! I looked at the possibility of acquiring Aquilim (Renia), EcoWeld and HALLER Hirschkleber in Ukraine. It turned out that only HALLER Hirschkleber is proposed from local suppliers. Considering that there is a warning “Do not freeze” for all these adhesives, I’m afraid to take risks and order international delivery - we already have temperatures below 0 at night.

You should be able to find something like weldwood at your local hardware or wood work supply shop. I understand about the freezing part, and it would suck to order and have useless glue. Try local first. You can also use white glue like elmers, but the other formulations (Weldwood etc) are better.

-

-

Reina make a series of latex based glues that are very popular and strong. Aquilim and a few others. I also really liked the water based glue that Tandy sells. Cant remember the name of it, but its very good.

https://www.tandyleather.com/en/product/ecoweld-water-based-contact-adhesive

-

I deliberately solicit feedback at one year and two years out. Good to collect that kind of data. Also good to be proactive should there be any problems.

-

1 hour ago, Riem said:

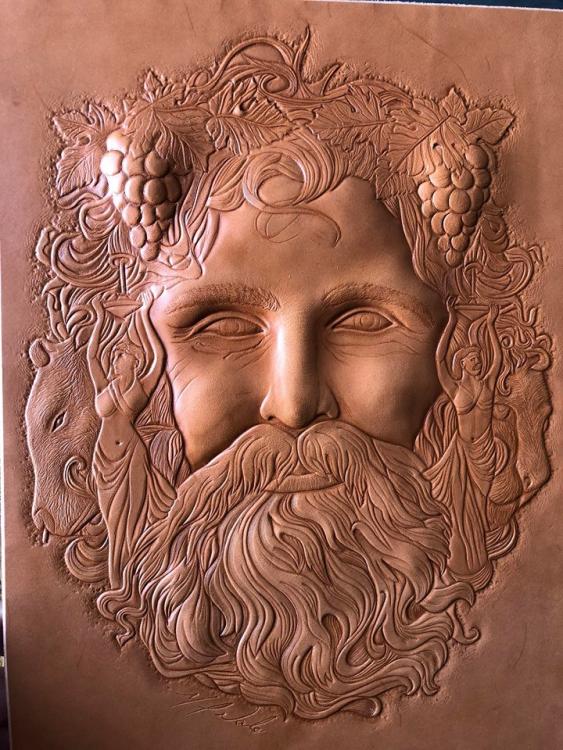

Wow! Hey Mike, this is so good you can give up your day job! This ain't 'leather work'. It's leather art!

I don't have a day job! Now what do I do?

-

Wow....5k views! Thanks everyone!

-

16 hours ago, JLSleather said:

YOU KNOW better 'n' that... SOMETHING in the pic for SCALE

Carving looks good... kaint tell how far it raised though -- did I already mention some SCALE?

Be nice to see how you color this one.. them grapes should be good learnin's

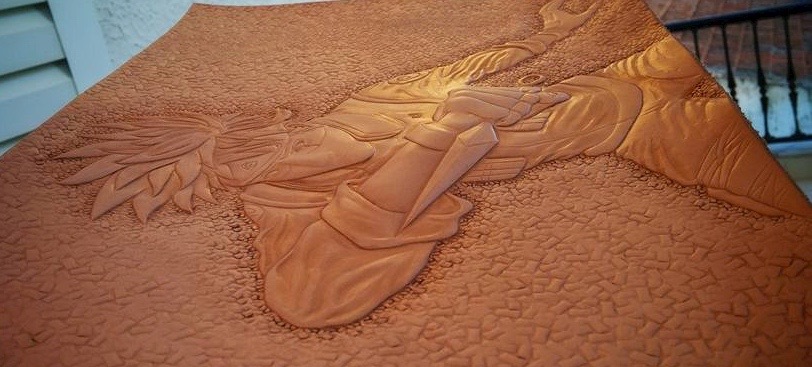

It's raised just the right amount. Too little and why bother, too much and it looks unnatural. Scale is irrelevant, as each piece is raised just the right amount for the size of the carving, which is far more important that a static measurement of how far it's raised. Found that one out early on in my embossing career. I figured more is better, but it turns out there are physical limitations to embossing leather. Especially the trade offs between the stretch of thinner leathers and the extended depth you can get with thicker leather.

This piece wont be colored, but grapes are easy. Peter gave me a class on this exact technique. Essentially, thinned spirit dyes in varying degrees of intensity. Looks difficult, but it's not. -

8 hours ago, bikermutt07 said:

You tellinge you only started leather work 6 years ago? Or that you only started carving 6 years ago?

Either way, your embossing is beyond any others' I have seen around here. (No offense anyone).

I always drool over your stuff.

yessir. September, 2012. Thank you!

8 hours ago, Scoutmom103 said:That looks amazing.

Thanks, turned out nicely.

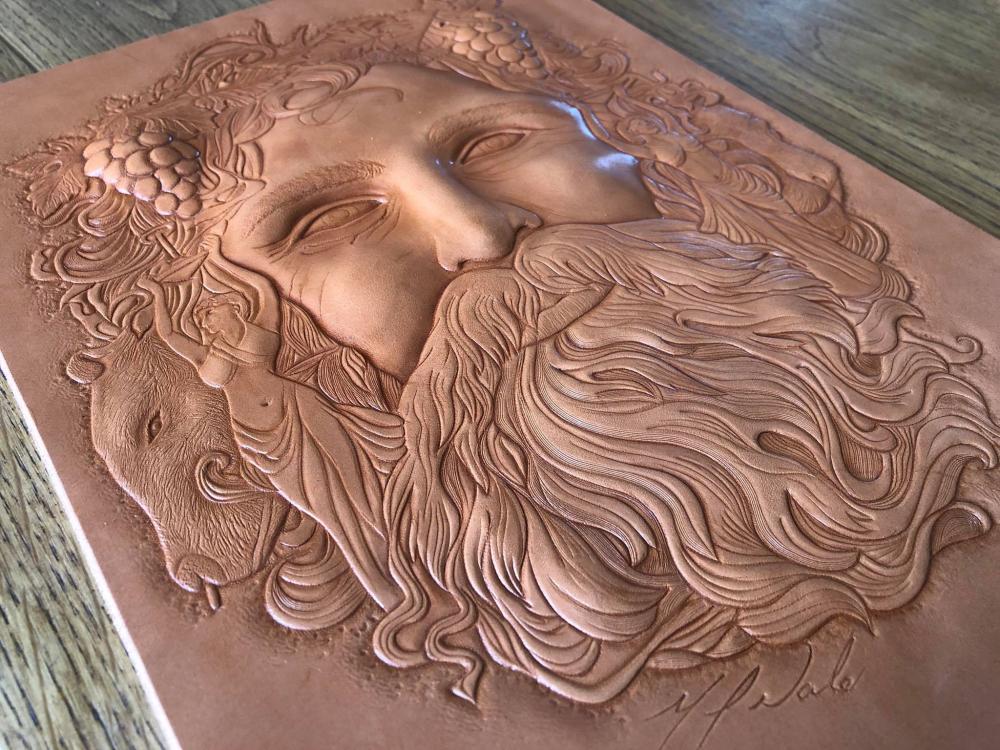

8 hours ago, TSes said:Excellent job. The face almost looks real. Great detail in the hair and beard.

Thank you! Facebook wanted to tag several people when I took the picture!

7 hours ago, noobleather said:Wow such awesome work! How many hours roughly for this leather work of art.

Hope to be at this level of carving in 5 and a bit years,lol.

I have maybe 6 hours into this one? The hair took a long time.

6 hours ago, garypl said:Beautiful work Mike! Any estimate of how many hours you have into this piece?

Gary

6-ish.

4 hours ago, battlemunky said:Sick work Mike!

Thanks man!

-

You got plenty of time man. It goes quickly!

-

13 minutes ago, Ragingstallion said:

well, you have been doing this for a long time....it's experience! im sure at some point in my life I will have the same mindset as you, however....almost all of us here have the artist mindset, where we are our own worst critic.

Ive only been at this for 6 years. Got my start right here.

8 minutes ago, Rockoboy said:@immiketoo Where the carving is most pronounced, in the cheeks and nose and forehead etc, do you fill the back with anything?

Yes, a sculpted leather plug fills the void.

-

2 minutes ago, Ragingstallion said:

Every time you post...i can not help but drop my jaw slightly. your work is always looking great, and a positive outlook on leather working. I, like probably many....MANY other here hope to achieve what you have with your skills.

Thanks, bud. It wasn't too long ago that I had those same feelings about people's work I saw here. I am always willing to help if I can so feel free to ask questions!

-

Like an angry Greek woman thing? Could be more accurate than you know!

-

You can always order online as well.

-

The single best piece of advice I can give you is be patient. Let things like dye, glue and finishes DRY completely before moving on to the next step. Read a lot, and practice before committing to a project. Maybe run down to Tandy and buy a few kits that catch your eye/. Good way to get started without breaking the bank.

-

1 hour ago, robs456 said:

Beautiful. What will you do with it?

The girl to the right, is she yelling? I don't get it...LOL! I'm not sure what happened there...time to break out the modeling spoon. Must have miss hit something there

EDIT: Took a closer look. Mostly a trick of the light, creating shadow where the mouth details are, but it did need some fine tuning. That face is the size of a finger nail.

-

-

Can't wait to see what you make. Also can't wait to get my hands on some horween!

-

1 minute ago, Handstitched said:

Thats what I thought too. So I did. I had to diversify where I live, and not just in leather.

When a customer asks me " have you ever made one of these?.... No, but I'm happy to learn " would be my first response . Or " I've never made one before, but I like to find out" etc. So , thanks to the faith that some customers have had in me over the years , as well as my own yearn to learn , I've been able to learn all sorts of leather related jobs, harness repairs, hand bag repair, custom jobs and/or repairs etc. These jobs I would have refused in my early days.

But, I have also done so many things in leather purely for my own edification ....and, purely for the fun of it . Its a case of, " Stuff it, I'm gonna make one , and I don't care if anyone likes it or not "

Just like a leather hat I'm ( slowly) making , theres no market for them here....but I wanna make one anyway

Just like a leather hat I'm ( slowly) making , theres no market for them here....but I wanna make one anyway  Its also good advertising .

Its also good advertising .

But now, I also do horse rug repairs, and canvas repairs etc.

If I was to be a ' one trick pony' I never would have survived as long as I have.

HS

This is the best example of why learning new skills is important. That and keeping your sanity!

-

In reality, me too. I am good at a few limited things, and I need to expand the skill set.

-

Thanks, everyone. Hope it helps demystif-eye the technique

-

Well, shoes are as complex as saddles I think. It's normal to be intimidated by them. I'd like to make a pair or two as well.

-

Its probably stitched inside out and then turned right side out.

-

22 minutes ago, chrisash said:

I have a gladstone bag on my bucket list made of good veg tan baybe sedgwick with goat inside and brass opening top and hand stitched.

Maybe someday when i get enough spare dosh

Maybe

Maybe

Damm now look what you have started

Maybe

I have projects like that. But I say maybe one day when I'm good enough. I hate the waste of the learning process sometimes.

-

I hear you there. I can round braid pretty well, but only as lacing projects. Stand alone braided items elude me.

Solvent-free leather glue

in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Posted

Excellent. Looking forward to hearing your reviews.