-

Posts

96 -

Joined

-

Last visited

Profile Information

-

Location

Manitoba Canada

LW Info

-

Interested in learning about

stamping, everything and anything!

Recent Profile Visitors

2,543 profile views

LBennett's Achievements

Member (2/4)

-

Thank you very much for posting this! I am looking forward to giving it a try !

-

i spent just under $800 got an extremely well maintained and used Consew 226r-2.. I build mainly belts, spur straps and some chaps, chinks etc. I've sewed up to 15oz weight leather with it. So you can find less expensive machines that will meet your needs but you will need to look around and really pay attention to do so. Out of the machine brands you mention though I'd go with the Juki or the Techsew just personal preference

-

If i had that situation.... Cobra 4.

-

Consew 226R-R With No Bobbin Tension......

LBennett replied to LBennett's topic in Leather Sewing Machines

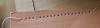

Yes ordered a new bobbin case and it has been working beautifully since. I realised when I took the old bobbin case apart to look at the spring, that the spring was very worn, even had a bit of a groove forming in it. That is what the stitches look like now. ( the picture)- 10 replies

-

- thread tension

- consew 226

-

(and 1 more)

Tagged with:

-

-

Consew 226R-R With No Bobbin Tension......

LBennett replied to LBennett's topic in Leather Sewing Machines

Thank you all so much for the replies! lots of very helpful advice. I have ordered a new bobbin case, but am also giving everything a good clean to make sure that "gunk" wasn't the issue. I'm saving this thread to my computer so that I can remind myself of steps and problem solving tips . Linda- 10 replies

-

- thread tension

- consew 226

-

(and 1 more)

Tagged with:

-

Consew 226R-R With No Bobbin Tension......

LBennett replied to LBennett's topic in Leather Sewing Machines

Sorry I didn't specify how long ago we brought it in. Moved it into the house about 2 months ago, so lots of time to come up to temp. and the Thread is all stored in a container in the same room as the machine is in. I've tried to tighten the spring on the bobbin case, and it is as snugged up tight as I can get it, but there it still no tension on the bobbin thread. I was wondering if it is possible that the spring is shot on there? Thank you very much for the reply Ferg. Linda Also, I tried stitching with 138 on the bottom and 69 on the top, and then i got a beautiful stitch... and that seems very odd to me. I hadn't paid attention to which bobbin i had put in, and had grabbed the 138 instead of my usual 69.- 10 replies

-

- thread tension

- consew 226

-

(and 1 more)

Tagged with:

-

Ok, I have a Consew 226r-2. Had great even thread tension when I first got it, had it set up in my garage. It had been used mainly for Upholstery jobs prior to my getting it. Then when I moved it into my house ( sewing in an unheated garage when the temps are 50F and under, wasn't going to happen, and now we've been -38F a few mornings i'm glad i brought it in) but i digress.. since i brought it in i've been having tension issues. thought i had it sorted out, but was wrong. When i stitch 95% of the time the bottom threads loop is showing on the topside. once in a rare while it will be just right and the knot won't show top or bottom, but as i said that is rare! I've read the manual multiple times, gone through all the adjustments for tension for both top and bobbin.. and still no love. I can pull the bobbin thread and there is almost no resistance at all... I'm just at a loss at what to do to figure it out. I attached a couple pictures. the one on the dark leather is how the stitch looks most of the time, the spur straps show it doing it's sometimes nice, sometimes off stitch, and then the other pale leather is the one time it seemed to be stitching just right...

- 10 replies

-

- thread tension

- consew 226

-

(and 1 more)

Tagged with:

-

Over Whelmed With Leather Type

LBennett replied to stef73433's topic in Saddle and Tack Accessory Items

I like to line with Latigo if it is for a horse that is going to working and sweating.. find it is best for gear that is going to see lots of wear. -

-

-

-

-

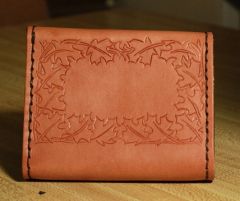

It is full strength saddle tan dye, and then I "antiqued" with gold acrylic that I then rubbed off. the flowers I had dry brushed colour ( acrylic) just before doing the gold. Thank you for the compliment! this was a trial and error piece, but both my Mother in Law and I were happy with how it turned out.