-

Posts

136 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by arz

-

Abbey England has stainless (as well as brass, antique brass etc.). They told me they can offer any finish I want for all their buckles, they just don't list all the finishes on every buckle. I just ordered some stainless, however I am located in Romania so shipping is cheap for me. Since you are located outside of the EU you would pay 19% less than me...it might make it worth while for you... Buckle Guy is good but sometimes they just don't have what I am looking for (for example brass colored watch buckles!). Finding good quality hardware can be hard! Hope you find what you are looking for -Adam

-

@Trox Thanks again. I'm comfortable doing this. I did some research and it seems to be a common thing to do. This 220V machine uses 750W total. So they are not large motors. Now I just need to fine a controller that is around $50-100 All the local ones seem expensive. Setting up a business is expensive so I'm trying to save everywhere I can!

-

@Trox Thanks for the detailed info! This is a basic machine, no servo or electronic control. Atom in the UK sent me the manual so I have the electrical schematics. To be honest it may be able rewire it for 220V (it maybe 220/380V). I should have looked closer at the motors when I saw the machine. I think the dealer just doesn't want to deal with it. I have done a fair amount of electrical work in the past. Looks like the controller would be easy to do. Could I just take the existing power cable and wire it into the controller (instead of wiring it directly into each motor)? Thanks! -Adam

-

Hmm...sounds easy enough. How much does a frequency controller cost? This machine is just like yours but does not have a servo for the feed.

-

@RockyAussie Thanks! This one has two motors: One on the right that has one belt that controls the knife/clutch (inside the machine is a typical clutch setup with a belt that goes to the feed clutch). The second motor is on the left cabinet that powers the vacuum.

-

The dealer said they cannot change the motors to 220V. I would have to replace the motors etc. I'm not sure how involved that would be. We are busy enough at the moment so that option does not appeal to me. He is looking for another machine for us. I can wait so that's fine with me

-

@Trox Thanks! I would like to buy the Italian one. I am now waiting to here back from the dealer if they can change it to 220V for me (this one is currently setup for 380V). -Adam

-

@Trox Thanks for the info! Our small shop is in our third bedroom in our apartment. That is why I was leaning towards the Chinese machine, it is quieter (don't want to disturb the neighbors). However, I do have another room in a retail space about ten minutes away (rented for another purpose). I could put the skiver there. Not great, but it will work until we can rent a better shop. I appreciate the advice that all of you have given, it has been very helpful! -Adam

-

Update: I emailed Amy Roke and we exchanged a few emails. In the last email I sent (May 29th) I asked them if they considered this normal wear for their poly thread and if this is what I should expect. They have not emailed me back a response to those questions. I also talked to a very good leather worker on Instagram and he has had the same problem, so it is not just me My advice and conclusion is not to buy these threads. I would not want anyone else to spend the amount of money I did and have the same experience! -Adam

-

You are welcome!

-

I use the FN2M (I said FN2 in my first post, should have been FN2M) for everything (it is the only creaser we have!). It is a perfect size if you can only buy one. We use it for wallets, watch strap and even belts. The mm spacing depends on how you want it to look. I like the one we have because I crease it, then the crease acts a guide for my pricking iron, thus giving me a perfect 3mm distance from the edge. I would love to have more tips in the future for variation. The FN2M gives you a 0.5mm crease line about 1 - 1.5mm from the edge, the crease is very close to the edge. It also rounds the edge just a bit. Basically starting from the edge: it rounds it, a 1mm space and then a 0.5mm crease. The FN2M works great for watch straps, it is small enough. The regular F tip from what I have heard gives you a thinner looking crease (sharper) and does not round the edge. Look on Instagram and you should find photos showing the difference between them. The F1C I believe is a shorter version of a F tip. I would only buy that if you are doing really short items or very tight curves. You can crease with a S tip but you will have to use a ruler, that would be much slower than using a F tip etc. We only have one handle and it has been fine. However, you do have to wait for the tip to cool before switching. Once we can justify it (get busier!) then we will be buying more units. If you are only doing this as a hobby or can wait for the tip to cool you will be fine with only one. I hope this help! -Adam All our photos on our IG account use the FN2M tip, https://www.instagram.com/atelier_zander/ Here is a photo with the FN2M on about a 22mm belt :

-

We have used this tips for hours, so we have learned what works etc. We have the wax spatula and the FN2 creaser (they are $$$$!). The wax spatula gives you a large flat surface to help smooth the wax paint, it does not get real hot on the tip. It works very well in the later stages. I wish I had a S 0.5mm tip for two things: 1. for very small items where space is a issue, 2. A more concentrated sharp edge for the first shaping of the edge. For example, when doing wallets sometime where there is a fold I have very limited amount of room, this is where the S tip would be nice. If I were to do it again I would buy the FN2 (wonderful!) and a S 0.5mm tip. I have used the F2N for smoothing the edge but the paint will sometime stay on the tip. When creasing I want that edge perfectly smooth. You can clean it but it is not ideal to use it for the edge. At least that is my view on it If you have any other questions I would be glad to help if I can. Hope this helps, Adam

-

@RockyAussie Thanks! I use mostly Alran goat and veg-tan from Italy (2mm max). I will let you know what machine I buy. Either way I will need to buy a better foot for it. -Adam

-

The Chinese one does not have a vacuum. The cheapest Chinese with a vacuum I can find is around 2,400 euro (Sieck.de). This is much much less! So the vacuum is that important? -Adam

-

Also, I now have access to a band splitter (about 2.5 hours from me). So I can now have someone split my goat leather down to 0.5mm for lining. I really only need the skiver for edges and maybe wallet pockets... -Adam

-

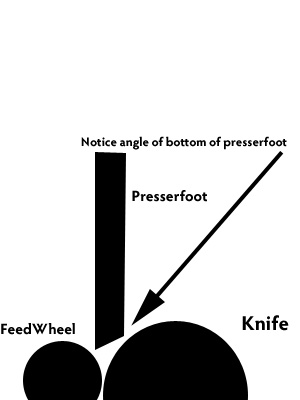

I'm sorry the drawing does not make sense I think what you described it what I was trying to say, I probably have the angle going in the wrong direction in the drawing. I'll go try the Chinese model and then choose one, although from what people say the Italian model is probably better. This one is the same as a Atom GL12CTN. Thanks! Here is the only photo I have of the machine:

-

Update on skiver purchase: I looked at a typical Chinese 801 today and a used Ellegi GL12CTN today. The was the first time I had used one. On the Chinese model the belts could be set so that there is a different ratio between the knife speed and feeding speed. Both are the same price. I'm trying to determine which will be better for my needs (see post above). The used machine was in good condition, all the covers and parts were there, no rattling or bearing sounds etc. It seemed mechanically sound. It has a new knife and a vacuum. It is set up so that the blade runs continuously and the feed is controlled by the clutch (foot pedal). It however skived pretty bad (bunching up, tearing, not skiving straight etc.). It was a harsh reality of how important it will be to set it up correct (my wife was not impressed!). I am assuming that it is skiving bad because of: A. poor setup, and B. A new blade that has not been sharpened correctly. For example, they did not even know you have to remove the burr inside the knife. I also think they had the depth gauge on up-side-down. Also, it had a standard looking presser foot (about 55mm) shaped the same as the radius of the knife. However, if you look at the foot straight on (towards the back of the machine) it was beveled, not straight. Is that normal? I have attached a very simple drawing to show what I mean. I'm not sure what machine will be best for me. The new one will have local service, quieter. While the used one will need a little care given to it and I will be on my own... Thanks! Adam

-

Yes it is. -Adam

-

Thank you for the tips but I am hand stitching. I'm sorry if I put this topic in the wrong spot -Adam

-

Thank you for the interest! Same thing. The belt above I did wax before sewing. I would say it makes it worse... I am in contact with Amy Roke. I appreciate that they answered my email and are looking into it. I don't want to cause them any trouble or be difficult. Amy Roke thread is loved by many people so it is probably just some of my thread that are doing this. If this was happening with other threads then I would mark it down as user error. However, I have no problems with Lin Cable or Tiger, and we have sewn a lot of items. What I would really like is to hear the experience of other people who have used the Amy Roke poly and have tested it in real life wear.

-

Someone on Instagram suggested I use a hairdryer to melt the wax back into the thread. After some work this did work. Is this normal? I did not add any additional wax to this thread. I do not have to do this with Tiger or Lin Cable. Is this a manufacturing fault? It is not worth my time to melt the wax back into the thread. Thanks, Adam

-

I sent Amy Roke an email, giving them the same details here. We will see if they respond...