-

Posts

136 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by arz

-

Intrecciato woven pouch

arz replied to Hahn's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice, I like it! Looks like that took some time to make -

Orders to ship

arz replied to Mattsbagger's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice work! I think when I worked in printing I saw repair techs use them. I also think I saw a Xerox repair guy with something like what you made. The versatility of leather is amazing Plus you found something people are willing to buy...very hard to do. Congrats! -

Hello Michiel! I did not see that post. Thank you! Just what I was looking for I think 92 (M30 thread) would look good for my items. Thanks! Adam

-

Hello, I posted a while ago about the difference between an Adler 69 and 269. Thank you for the help! The 269 machine did not work out. The only one I can find is just too expensive for me. I read everything I could find about the Adler 69. I think this would be a good machine for me to start on. I have read and heard conflicting opinions about what size thread this machine can use. What is the maximum thread size I can use in an Adler 69-373? What about in the bobbin? These machines are easy to find where I am (Romania). Plus parts are easily obtained. The mechanic I talked to said he has it set up for size M20 (#138 thread). I thought it was only able to handle M30 (#96)? I need a machine for bags, wallets etc. Total thickness of 4-5mm (10-12oz). Thank you for your help with such a simple question! -Adam

-

I appreciate all your help. It is working great! Splitting is still a challenge but I am no longer putting holes in things Now I am looking at sewing machine for the future (I don't think I can continue hand sewing in the future....) -Adam

-

@dikman Thanks! I have heard the stitch is not as good looking. I will go do a test to see if it is good enough for what we want. Even if we use it for turned bags, hidden pockets etc. I think we will need it in time. I can only hand sew so fast....

-

@wizcraft Thanks! I will wait and see if anyone knows about the Adler 269. I have heard it is a great machine. It is kinda rare around here, that is why I am thinking of getting this one. However, I don't want to spend $500 and then find out I have to put $1000+ in it My old skiving machine worked out great though. I paid $250 for it with a vacuum etc. It works great! The problem I have found is the cheaper used and new machine only go up to about #69-96. That would be an Adler 69, Juki 245, Pfaff 335, and the clones that I can find locally. If money was not an issue I would just go buy a Adler/Durkopp 669 and be done with it. Maybe one day!

-

When you say 2-3oz do you mean total thickness? The minimum combined thickness we use is around 4-5oz (sewing wallet pockets etc.), max around 10-12oz (2 layers of 2mm (5oz) leather. So would #92 thread be good for a total of 10-12oz? Or would #138 be better? I realize some of this is personal preference, look, machine etc.

-

@Wizcrafts Thank you! Very helpful advice. So it seems the Alder 269 might be overkill for what I need. Do you know what the max thread size is for a Adler 69? I am very familiar with saddle stitching buy not machine. I want the best looking stitch I can get, a slanted stitch if possible. I think I can get that with a machine if I use the correct needle????

-

I forgot to mention we use Italian vegtan and French goat. Max 2mm leather. We like a finer Euro style in general.

-

Hello, I am looking at buying a used sewing machine. I have NO experience with sewing machines We make slim card wallets, bifold wallets, clutches (with gussets), small bags etc. Normally we are using a total thickness between 2-6mm (very rarely above that!). Thread Serafil #20 or tex 138 (532 for hand sewing). I am getting tired of sewing by hand. I would like the ability to use up to 138 thread in the bottom bobbin. I have the chance to buy a used Adler 269 for a very low price. (less than $500). The seller "says" it works great. I would be able to test it as it is only a few hours from me. I would have to buy a servo motor for it etc. What do you think? It has the old Efka variostop motor (380V). Would I be better of with a Adler 69?.They are very common here. I can get a one from a used dealer (they look good) for around $500. They also have a nice Pfaff 335 and Juki 245. Thanks! -Adam

-

I bought a 30mm roller and a 54mm teflon. For splitting I have found the teflon better. Thanks for your help. A sharp blade has been the most important part for me If the skiver blade is perfectly sharp it is MUCH easier to use. -Adam

-

Sorry I haven't posted in a while I have used my belt for almost a year and it still looks great. I used hide glue on mine and bees wax for my brother in laws. Both look good. Using the hide glue works well, just make sure not to put too much on or it will get sticky. I now sand, use Tokonole, and then use 50/50 bees wax/paraffin. I found it was important to make sure I used enough wax. Also, using my heating iron works very well to spread the wax. Of course the smoother you get any edge the better. Also, I apply Tokonole, sand, apple again sand..etc....this will get a very very smooth edge. AFTER that apply bees wax etc. So far our wallets/clutches are holding up well. You can see some of our edges here on our Instagram account :atelier_zander Atelier Zander Hope this helps! -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

Very nicely done. Your skill with fabrication always amazes me! -Adam

-

I will give the tallow a try! If it is more efficient, great -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

I use the wood strap cutter. To me the edges are not OK, just not as smooth as I would like. Maybe if I used a plough gauge it would be better. I just can't invest in one at the moment. I agree that I probably used too much glue. I will try again. I also found some beef tallow, that will probably fill in the voids I am sanding out now. I found it at a fancy food store Thank you for all your help! -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

Thanks for the tips! I really liked the way the hide glue looks, goes on very easy etc. However, it was very humid in Romania this Summer and the edges got sticky, and then turned just a little off-white and cracking. Probably the heat/humity reactivated the glue. Maybe I put too much on??? At this time I will just go back to using Beeswax. I have found, sanding, edging, burnishing with just water, dying, and then burnishing/sealing works pretty good. I also think I am being too picky with the edges. I can't spend an 1-2 hours doing the edges on one belt...I would never make any money Perhaps a motor burnisher and sander would speed things up... Thanks! -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

I bought two of the Pro Edge Burnishers for a Dremel. The quality is good. I wish the grooves would have been a little deeper. They work good for small things like wallets. I don't really like them for belts, I can do it quicker by hand. I think for belts a larger one in a drill press or grinder would work much better. -Adam

-

It depends on what tool you need/want to buy. Here is what I have learned. I find I need a tool, I research what is available, then buy the very best tool in that class. I am not brand loyal, I buy what will get the job done. In most cases you pay for what you get. Normally if I try to save money it comes back to hurt me! However, I bought some $5 hole punches from leathercrafttool in Japan and they work very very well. I bought a French skiver by Barry King, very well made. I also have two english point punches from Jeremiah Watt, also superb. I really, really like the $20 Japanese knife I bought from leathercrafttools.com. I can get the knife so sharp it scares me! Overall the tools from Goodsjapan and leathercrafttools are good, in fact better than most Osbourne tools. Osbourne is mixed for me. The quality is OK, but not close to Barry King, Jeremiah Watt, etc. They are however one of the only companies for example to make a V groove tool. If you know how to sharpen tools I have heard their punches are OK. I have some Blanchard tools. I think they are better than Osbourne but not as good as some of the American tool makers. Their shoe hammer is nice and I like their awl. I use Wuta pricking irons and they are great for the price. I would really like a set of KS blade pricking irons and punches! I have heard they are amazing. I hope this will help! -Adam

-

Safety beveler vs a spokeshave

arz replied to T Moore Medicine Hat Saddlery's topic in Leather Tools

That is interesting. I have the sliver Osbourne and have mixed feelings about it. Sometimes it works great...other times I give up in frustration! Sometimes I think the angle is not right. I never thought the black Tandy might work better. I far prefer a very sharp English paring knife, skiving knife from Japan, French skiver etc. The nice thing though about the safety skiver (potato skiver) is that you pull, so for very small items etc. it works nicely. Maybe in the future I will try the black skiver and see if it works better than my silver Osbourne.... -Adam -

I can't think of anyone else in the US that sells them. I am located in Europe so I order from Mando. It "might" be cheaper to order through them. You would save on the taxes and they will ship worldwide. You have to be patient when ordering from them. Also, they will be on vacation for the entire month of August. -Adam

-

Have you checked the below companies? https://www.rmleathersupply.com/collections/machines/products/electric-edging-tool http://www.fineleatherworking.com/leather-electric-creaser You can also order direct through Mando.fr -Adam

-

@Matt S Thanks! I tried two things yesterday. 1. With a quick burnish with water and soap and then a two coats of bee's wax (well 50% bee's wax and 50% paraffin); 2. Quick burnish with water and soap and then a final coat of pearl glue. The pearl glue was a much better finish. I scratched the edge VERY hard with my fingernail. The pearl glue was much better, it showed very few marks. I am very happy and think that is what I will go for. I am told that pearl glue will stay flexible and will not crack like some other hard finishes. That said, I will try some tallow before I apply the final finish as that has been highly recommend to me. I don't particularly like the smell of hide glue, but it is non-toxic and my wife is less bothered by the smell than I am I also like that it goes on quick. Here is the video I found that shows the pearl glue method for anyone who may read this: -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

@Matt S Thank you for your help! I searched for bridle edge finishing and somehow missed your post I will continue to look for some kind of tallow. I might have to order it online. I do have the Sedgwick leather conditioner that has tallow in it. It seems too soft though for filling in the voids. From what I read in your previous post, you first quickly burnish, dye, apply burnishing compound and then bee's wax. Are you using PVA glue as your burnishing solution? I find that the pearl glue gives a hard shiny finish that is easy to apply. I am not applying bee's wax after. I am still testing to see how well it will hold up. I can get the fibers to lay down great with a variety of burnishing compounds: water + saddle soap, Tokonole, etc. The leather burnishes very easily. But, unlike the Italian leather I use, the fibers about a day or so later want to come back up or a rough spot will appear. Anyway, it is nice leather to work with! -Adam

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with:

-

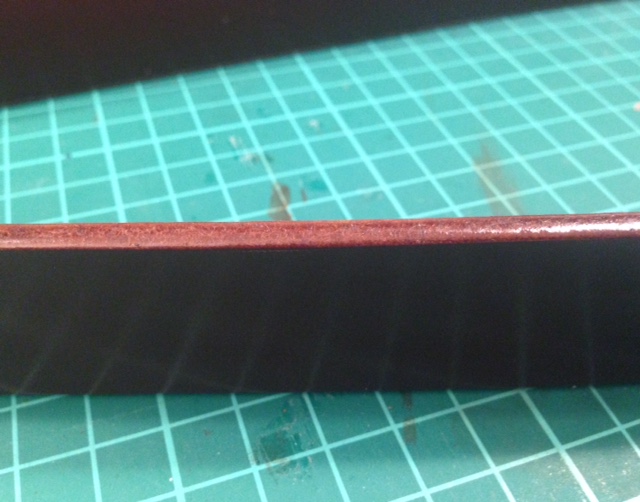

Hello, I am having a small problem finishing the edges of Sedgwick English bridal. I bevel, sand, burnish with water and soap, dye, then apply a finish. For the final finish I have tried bee's wax and pearl glue (a traditional English technic). I have of course tried other methods and the order etc. I am not new to burnishing (but I am new to English bridal) and can get great looking results. What I am concerned about is wear. One thing that has been recommended to me is to use tallow fat as a filler/burnishing gum. I just can't find any at the moment Here is my problem: The edges look fantastic! Smooth, great color and shiny. But...it seems they simply will not last. After a day or so of normal use, parts of the edge seem to dry out and then the edge get fuzzy or slightly rough again (especially around the buckle). It is not bad, it just doesn't look 100% anymore. I want my customers very happy and don't want the belt wearing after a week of use. I am currently waiting to see how my latest attempt will hold. Is this normal? Am I just being overly picky? Any ideas on what I may be doing wrong or how I can resolve this? Thank you for any help you can offer! -Adam Here are some photos of how my edges look when "new" Sorry but I do not have a photo of the problem I mentioned. I will try to get a photo when I get a chance.

- 20 replies

-

- english bridal

- belt

-

(and 1 more)

Tagged with: