-

Posts

242 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Everything posted by JRLeather2

-

What's happened to Hermann Oak?

JRLeather2 replied to buzzardbait's topic in Leatherwork Conversation

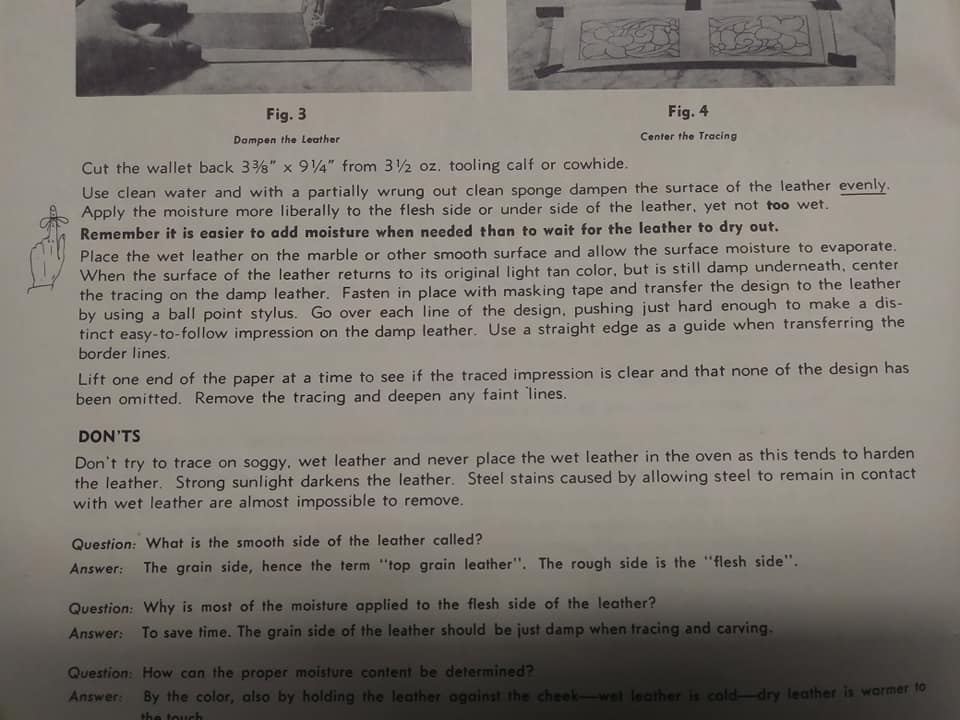

I bought direct from Herman Oak , "A" grade sides and they were terrible, sent the whole roll back. -

Oxcylic Acid will remove the stains after.

-

I use a spray bottle unless I am wet molding...I also keep a hair dryer plugged in by my bench If it takes to long to get where I want it...

- 55 replies

-

- 55 replies

-

https://www.fasnap.com/index.html

-

Need ideas for deer hide sheath

JRLeather2 replied to archeryrob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Need ideas for deer hide sheath

JRLeather2 replied to archeryrob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is a piece of milled leather, veg tanned and very flexible, but also toolable if needed. -

My best guess would be a large plate stamp, the type you use in a press....

-

Yes, Sir.

-

-

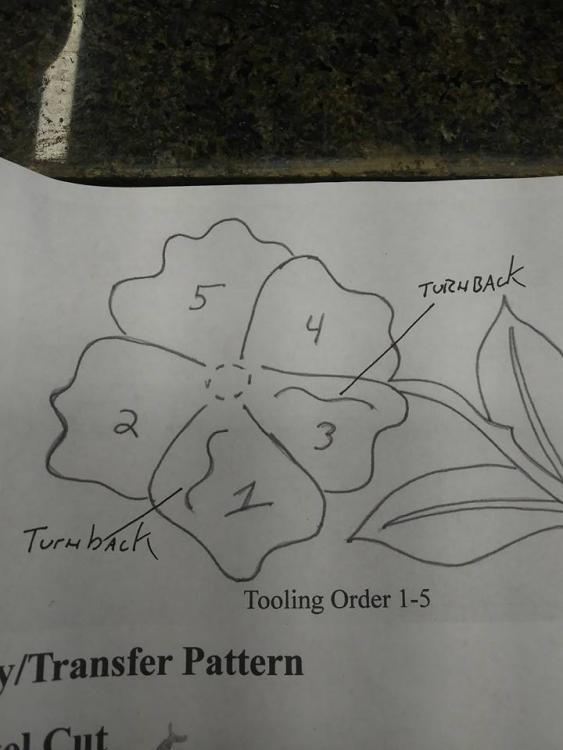

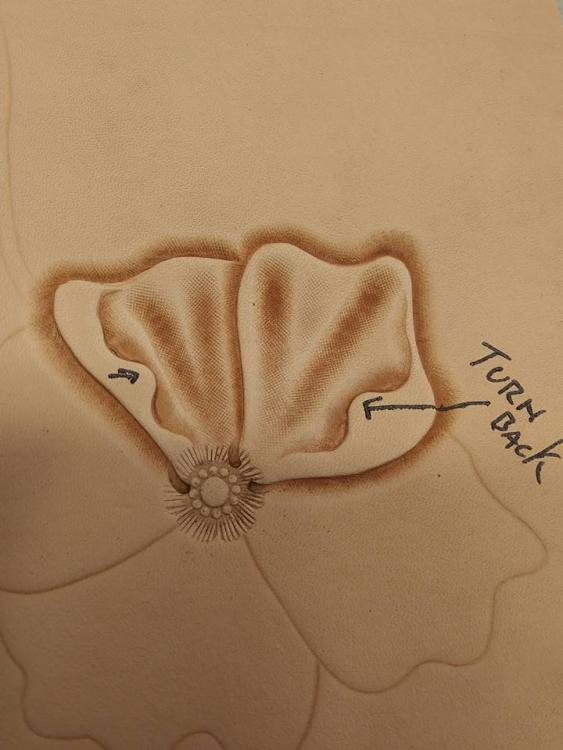

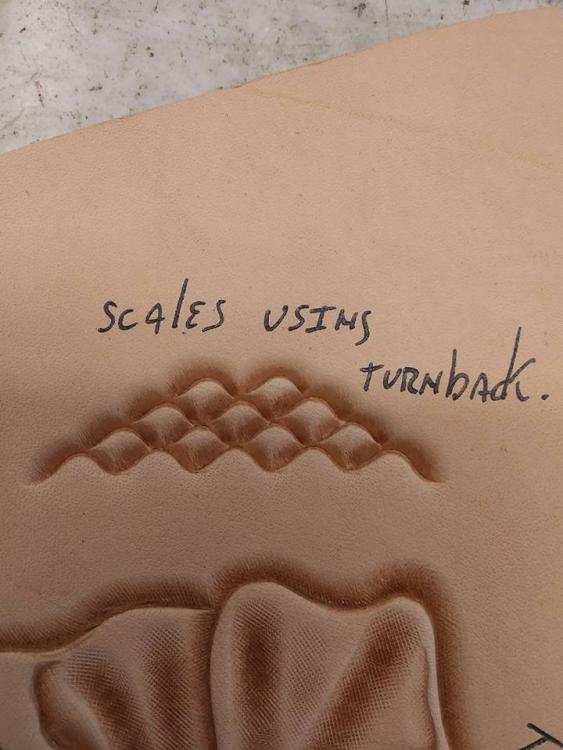

The T series are no longer made by Tandy. They are Turnbacks. I will post some examples of how they are used when I get to the shop.

-

Need ideas for deer hide sheath

JRLeather2 replied to archeryrob's topic in Gun Holsters, Rifle Slings and Knife Sheathes

-

Thanks for the kind words. I should also point out that was done with no swivel knife cuts and a single pass with the beveler. I also lean the beveler back to get the other line.

-

This one was several years earlier than to first... I think the flash on my camera washed them out a little bit.

-

-

Thread trimming scissors for normal guy hands

JRLeather2 replied to DonInReno's topic in Leather Sewing Machines

I use an edge beveler to trim, put it against the thread apply a little pressure and pull the thread into it. -

-

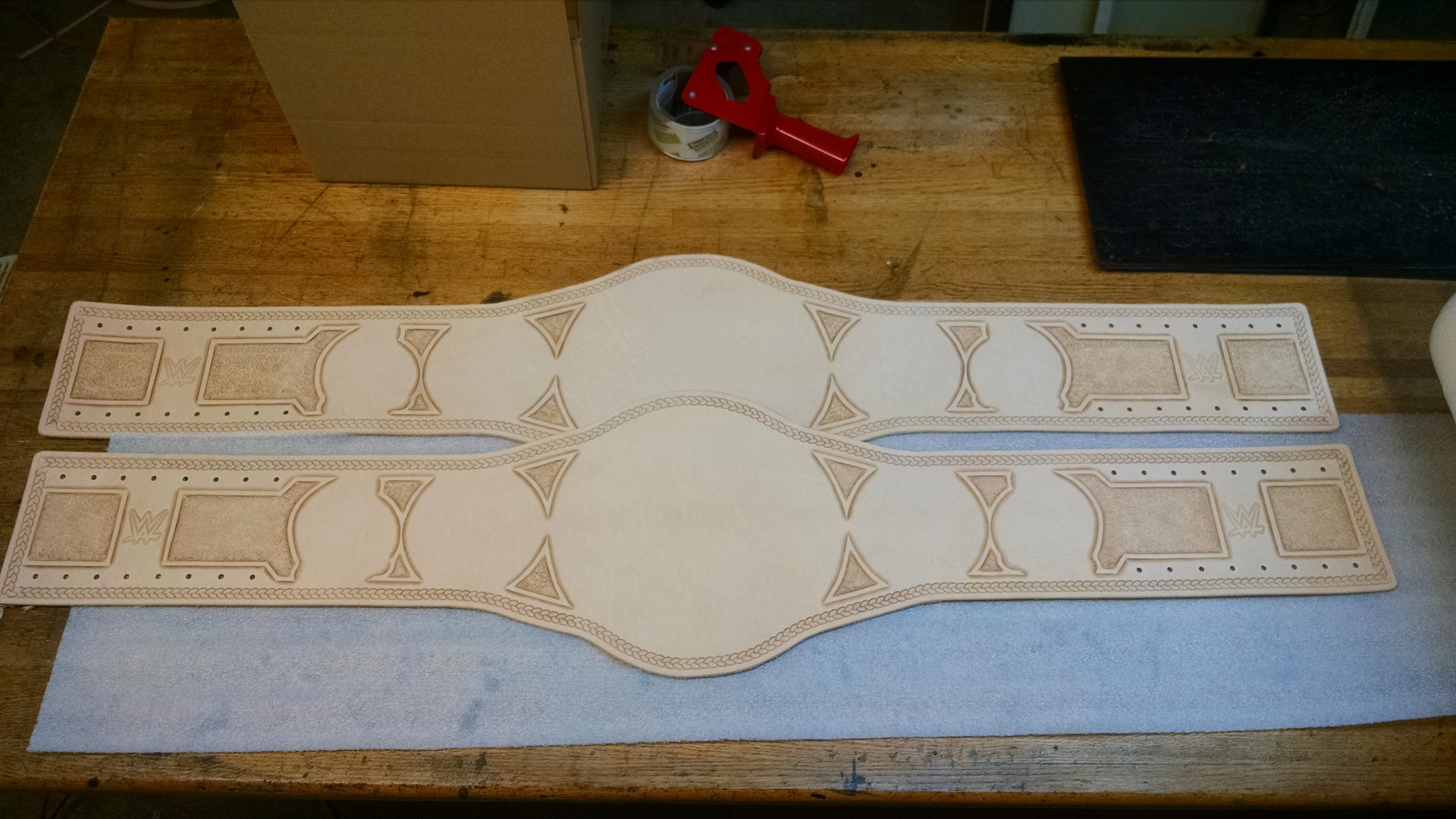

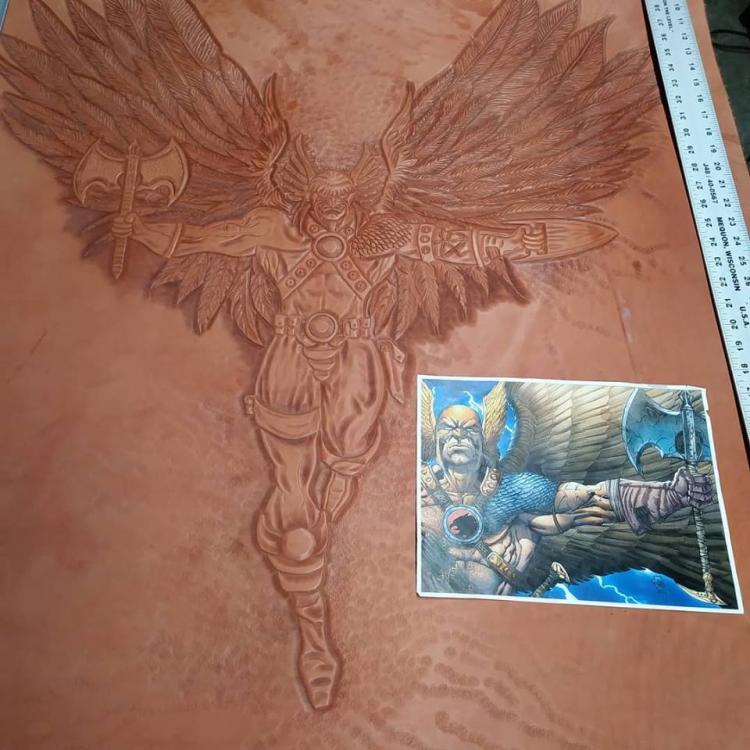

8-10 oz Wickett & Craig leather. Properly cased and beveled with a Tandy B803. Only tooled on the top.

-

Thank you all for the kind words!

-

-

Thanks. I don't know how or why the word got out but it has been blowing up. Yeah I have been doing the belt thing since September of 2013.

-

I stand corrected! I don't have much to do with that part of the business. I just tool leather. They leave my shop looking like the one on the top. And then after Andrew is done they look like the one on the bottom.

-

I have run my burnishers in my cheap drill press for years with no problems...