pokerinot

Members-

Posts

23 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by pokerinot

-

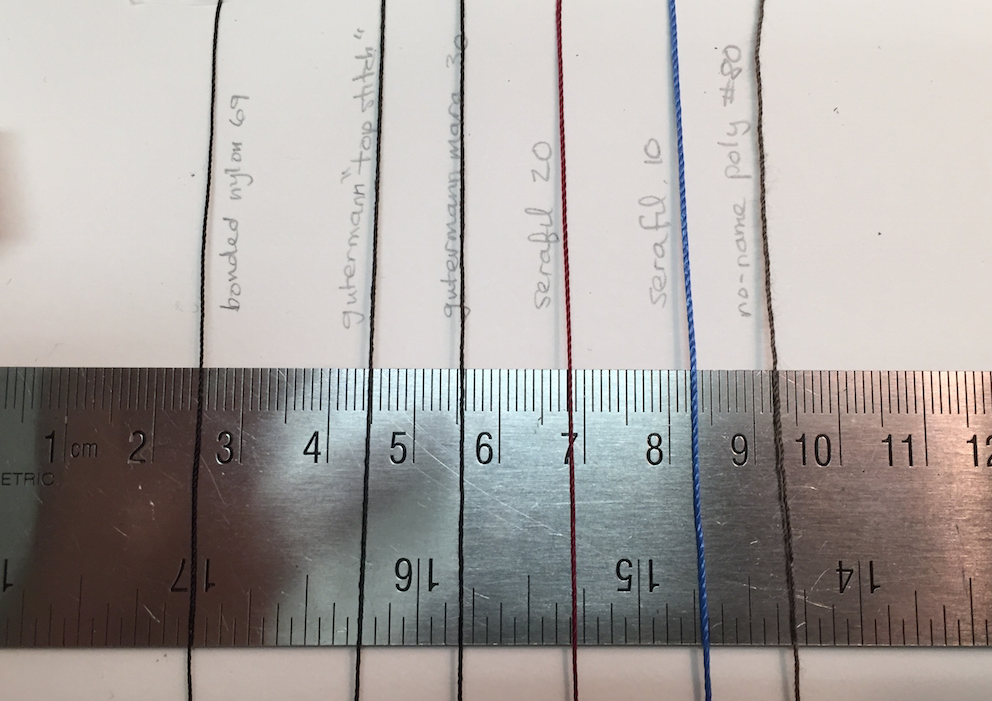

Late thank you to those who posted long ago! Here's a picture of some thread in case anyone finds this post and is wondering. I ended up ordering small quantities from Vacheta on Etsy and it is the most gorgeous thread! The 20 was not as large as I thought it might be though I would prefer the 30, I think. I am going to order some from JPM Supply Co. once I have set up an account to receive mail in the US (shipping price to Canada is mental!). The little spool I bought was $6 and more than enough to make a backpack. The Gutermann Mara 30 thread is also very nice: it has a nice shine and visible twist. I think it is well-suited to clothing as its very slightly fuzzy (very very slightly, not like the thread at far right which is cheap polyester no-name from a local store labelled tex 80). It is slightly nicer than the Gutermann polyester "top stitch" thread that I got at a local fabric shop in tiny spools for $2 and about the same size. Once sewn they both look quite good as any unevenness off the spool is tamed by sewing. The serafil is gorgeous, soft, shiny, no fuzzies, beautiful. I can't recommend it enough. If you can't read my writing, from left to right it goes: 1. bonded nylon #69 2. gutermann "top stitch" (green spool at fabric shop) 3. gutermann mara 30 4. Serafil 20 5. Serafil 10 6. no-name cheap "tex 80" polyester

-

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

For anyone who might be looking at this with similar problems: I just want to finish out this topic. My machine was able to be fixed. I brought it to a very good mechanic (luckily my city has these!). They were appalled at the state and quality of the machine --they weren't even sure they would be able to fix it. Luckily they could and it has been working as well as it can for the past couple months. It was some kind of gear issue deep within the machine that was causing all sorts of bits to wiggle when they shouldn't. I paid 2.5 hours of labour for a total of $150 which was a deal after an time-unspecified rate of $175 which I paid to Techsew for partial repairs, bringing it back 4x, and being told the problem was that my needle was slightly rotated. For what it's worth (and keep in mind they sell used machines so they have skin in the game) they do not recommend buying cheaper machines made in China. The steel is generally very low quality and they say that sewing at 25 hours/week the machines are designed to last for five years. (Mine is younger and with much less sewing time). They told me they sold one Chinese skiver to a factory and had to give a full refund after six months because the machine was toast. If anyone in or near Montreal is thinking of buying a machine, PM me and I'll give you their contact details because I can't recommend them enough. I also bought a brilliant little fortuna skiver from them which I love! -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thanks Wiz, It is a Techsew machine and I have taken it to Techsew several times! I'm trying not to dink with anything that I don't understand, and I think I'll bring it along to another repair shop when I check out skivers next week... It seems to especially hate this leather so I'll avoid it from now on! Your check spring tip helped a bit, I think. -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thank you again, Wizcrafts! I am doing this dance all over again and your comments are very helpful. Do you or anyone have an explaination on how to increase the alternating height of the feet and how high they should be lifting? The outer foot lifts quite high but the inside one doesn't. Also, I mentioned before the weird feeling that the material was being pushed forward as the needle went in. Techsew said they looked at it but I just took the face plates off and watched it and the feed dog very clearly shifts forward when the needle has just pierced the leather. Could this contribute to skipping stitches? I've backed off on the inside presser foot pressure because it seems like the pressure causes the shift forward (doesn't move when the foot is raised) but that didn't really work. Also the bobbin housing is making a god-awful racket so there's that too..... Anyway, long day, long rant. Thanks to anyone who is still reading -

Does anyone know where to order Serafil from? I'm looking for size 30 in colours. I'm in Canada but I'll order from anywhere but if in North America would be optimal. My google skills are failing me

-

those gussets

-

Super bobber (this is a good word!)

-

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

-

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Hi everyone, I'm finally updating now that I've figured out how to add photos (one of the jacket almost done and one of the finished state with accessories) The machine has been okaaayyy... I'm not completely thrilled. I got through most of the jacket with no problems but on the FINAL seam -a topstitch that closed the collar to the rest it basically reverted to skippy style. I tried that seam a few times (making a perforated mess of the leather --luckily it is hidden when worn but UGH) and then just went to my work to close it up on my machine there, which sewed it without hesitation and very predictably. I also have to sit down with the machine and have a stern talking-to about my expectations re: zipper tape. It skipped stitches EVERY SINGLE TIME I sewed crossways on zipper tape. Since then, I have sewn two bags with no problems (crossed fingers) but I have two more jackets coming up soon and I really need to sort out it's hesitation to properly sew uneven and multiple layers! That is part of sewing! And zippers! Lastly, I am attaching a photo of the bobbin case... It seems weird that there's a thread crossing the outside of it and I can't seem to make it go away... I have a feeling this is part of the problem. I've tried loading the bobbin with the thread in "p" and "q" orientations. When I got the machine back from Techsew the bobbin thread was not doing this. Am I loading it wrong? Bonus: visual evidence of my frustration with skipped stitches highlighted! -

Thank you both, I don't know how I missed these replies. I will see if a sneaky friend of my dad's can do the string thing...

-

Great bobber

-

Great bobber

-

My dad just adopted a 70 lb labradoodle and I want to make a (surprise) collar. I can't measure the dog from across the country, so wondering if anyone has an idea of how long to make this thing. Many thanks!

-

This is an old post but I can second the machine washing. Use very little gentle soap dissolved in the washer first if it's a top loader. Air dry or on a very low heat. If it's matted get a cheap pet "slicker" brush from the dollar store and brush it out!

-

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thanks everyone who replied! I actually sew leather clothing for a living at my day job (aka not on this machine) so I promise I know how to thread/ load a needle. That being said, I was hoping that I had been putting my needles in wrong by 180° as that would be so obviously fixed (and that they had somehow missed that the two other times I brought the machine in with the needle...not likely). I just spoke to Techsew - they have fixed the problem (needle was slightly rotated?) so that wasn't really a problem in the end (except that I can't believe that I've put the needle in slightly off every single time since xmas....) and they have fixed the stitch length dial which was the final straw causing my weepy phone call to them on Friday. I'm excited to get working so hopefully the sewing machine gods smile upon me and all of you too! I will report back next week just to end this thread on a happy note (hopefully!!!) Also, just want to say that as I said I am very familiar with the operation of industrial sewing machines but obviously not the mechanics and inner workings and I really find it impressive that so many people on this forum can fix their own machines. I hope never to live far from a professional, myself! -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thanks Ron, I'll phone at my lunch break. It seems like that can't be the only problem. I tried a few needles and put them in straight! If the one that was in the machine was rotated a bit I think it's because I threw it in there on the way out the door because I had put a number 20 in at some point when trying different things (and I wanted to give you the machine with my preferred settings). Does this account for the hook making contact with the needle? And the stitch length problem? Anyway I will be calling in a couple hours! -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

O NO! will request all kinds of torquage this time! -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thanks Eric, I actually just did that in the end after calling them because an additional problem sprung up on top of everything else. The earlier repair was under warranty. -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Have you ever come across the feeling that the foot moves the material slightly forward as the needle enters? Could this be related? This machine always has had that feeling but it wasn't addressed by the service I had (I didn't mention it specifically). I haven't seen this happen on other machines. -

Did I Buy A Lemon? Techsew Problems

pokerinot replied to pokerinot's topic in Leather Sewing Machines

Thank you Wizcrafts! I am making my way through this list, unfortunately none of the simpler problems seems to be it! I guess I have a lot to learn about hooks and shuttles and check springs(I can't find mine!). Thank you Wizcrafts! I am making my way through this list, unfortunately none of the simpler problems seems to be it! I guess I have a lot to learn about hooks and shuttles and check springs(I can't find mine!). -

I bought a three year old Techsew GC2603 this summer. It was skipping stitches so I brought it in to the Techsew guys for a timing adjustment as well as an basic once-over as the machine was new to me. Right after I got it back, it sewed about 6" and then the timing went again. I haven't been doing much work because of my day job schedule but managed to get my Christmas presents made without problems. Now I am trying to make a jacket for someone and the machine again is skipping SO many stitches. I can do a little tack properly but anything beyond that is random. I can't seem to get along with this machine! It doesn't help that all day at work I sew on a SunStar machine that never needs a second look, an adjustment, or anything, no matter what type of leather I throw at it. My current problem is mainly during topstitching, going through about 3 thicknesses of light-medium weight chrome tanned leather. I'm worried I'll never be friends with this machine!

-

Lambskin Dog Collar - Question On Finishing Seams And Lining

pokerinot replied to lightingale's topic in Sewing Leather

Looks great! If you're not certain that your machine will backstitch into the same holes, just lower the needle all the way and manually turn the work around the needle so you can stitch forward into the same holes. I personally would do 3 stitches then pull both threads to the back, trim, and melt with a lighter quickly. For the lining - I work in production leather and the way we would do this is to place your top piece on a rectangle larger than the collar -about 1/2" on all sides. After sewing, take some very sharp scissors and trim around, close enough to the stitching that the edges don't show from the front. The reason for the excess is to give you something to hold on to while trimming so you get a straight cut with no scissor marks.