-

Posts

1,904 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by UKRay

-

I'm looking for a way to sharpen scissors - any suggestions guys? Machines or whatever, I don't have a sharpening guy anywhere near me so need to find a solution that I can use myself and have no idea how to proceed. Hope you can help. Ray

-

Personally, I'd be inclined to lace the individual sections together rather than join them using chicago screws. Lacing just looks better somehow... It can also be repaired on the fly - unlike trying to find half a Chicago screw in the middle of a field. LOL Regarding sweat control, is there any reason why this couldn't be lined with a very soft lightweight suede. It would add substance to the project and provide a barrier layer. In addition, the contact adhesive / whatever glue you choose to fix the lining to the outer layer would act as a stiffener which would help to hold the shape of the moulding. Ray

-

Belt Pouch For Zippo

UKRay replied to BigK's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice design. There have been several good Zippo cases on the forum in the past few years but this is one of the best I've seen so far. RDB makes a nice one too... Keep posting the pictures! Ray -

Gesa, I have quite a number of tools that look almost identical to your Osborne stamps. They were made by Dryad in the UK, possibly in the 1920s and 30s. I would guess that yours could be a similar age. I'm extremely envious of leatherworkers in the US with access to those amazing old stamps. All my 'antique' stamps tend to be very small. Ray

-

Where's The Quality In "custom" Gone

UKRay replied to Chief31794's topic in Leatherwork Conversation

The whole issue of quality, as K-Man points out, is difficult. I sat down a while back and made my own list of characteristics that I felt embodied quality but I guess everyone has their own opinions. For me it has to be about workmanship, material and presentation combining to create a feeling of satisfaction with the product. Okay, that isn't exactly specific but I believe it is worth using the best leather/fittings, the best tools and machinery and giving the customer the feeling that they have got something really special and good value for their money. If I don't achieve that then I'm not delivering the best quality I can. Frankly, I'm not too bothered what anyone else produces (unless I see it as better than mine, in which case I obviously need to raise the game to keep up) and tend to concern myself with improving the stuff I make myself. Life is waaay too short to fall out with people I haven't met. I have quite enough trouble with the ones I do know! LOL Ray -

I started out with a Dixon plough gauge about 40 years ago and haven't found the need to change so far although I do have an old Merkle strap cutting machine that I use for very narrow 1/2" straps and 1/4" laces as it makes a cleaner and more regular job. In fact, I find the old Merkle machine makes a pretty good job of all widths, but it is a lot of work stripping and reassembling the thing when I want to change strap sizes so tend to leave it set to cut as described. I did try a razor blade type cutter a while back but didn't get along with it - although plenty of folk say they are great. It was almost too sharp (if that is possible LOL) and tended to take its own path instead of the one I chose for it. Do try a plough gauge before you invest in a machine. Used and in good condition, they are a fraction of the price of a machine and, IMHO, work very well. Ray

-

Instruction sheet from John Henry leather molding class

UKRay replied to Johanna's topic in How Do I Do That?

Thanks, J. Love the pics. Ray -

I'm with Skaid on this. In my experience, most kids will learn to do anything if they really want to. Just watch them doing stuff they have been told they can't do! Maybe showing him the belt with a conventional buckle and saying it is only for 'big kids' but if he can learn to undo it he can have it, might work. Good luck! Ray

-

Chris, there are lots of ways to work leather, but the only one you need is the one that works for you. My method is to cut out the leather bracer from 3.5 to 4mm thick veg tan, punch the holes for the lacing, tool the leather, carefully dye the project using a soft cloth like a bit of Tee-shirt (to enhance the tooling and bring out any grain in the leather), finish with sponged Atom wax and then dunk in a bucket of slightly warm water or dangle it under a tap. I then mould the bracer around whatever 'former' I have chosen to get the shape. If the bracer is a custom job I may need to 'bone' in details such as curves and 3D effects. I then leave the bracer to dry overnight on the former. I'm not saying this is the 'right' way to do the job, but it works for me. IMHO. the very best thing you can do is start by making narrow wristbands that allow you to experiment with tooling, moulding and finishing until you feel confident to move on to a bigger and more ambitious project. remember, we all have to start somewhere so start work and don't give up. Have fun, Ray

-

For short run work you might want to try an electric domestic clothes iron. Attach the magnesium stamp to the iron plate with heat resistant double sided tape, wind it right up to as hot as it will go and experiment. I had a tiny little travel iron that worked well for a while and allowed me to see the work as I applied the stamp. Obviously you won't get the depth of impression you get with an arbor press but with a 'sharp' stamp it will give you a reasonable impression if you are careful. Ray

-

Anyone Sell Wholesale Products To Retailers?

UKRay replied to woodandsteel's topic in Getting Started

IMHO, Consignment is rarely a good option for the vendor. Essentially you are funding the retail's business by supplying them with goods they don't have to pay for unless they sell. Effectively, you are providing an interest free loan. Financial institutions won't do it, so why should you? I sell a lot of stuff wholesale but always insist on cash with order. I then make up the goods to order so my leather stock is not tied up until I have the money in hand to pay for replacement materials. Okay, this won't work for everyone, but if you lay down the 'rules of engagement' before you start dealing with someone then there can be no arguments later. Good luck with your business. Ray -

Thanks again for all the kind words, folks. The tools and machines have been collected over the past forty odd years so the expense has been 'little and often' but until now I have never had a big enough workshop to put 'em in. LOL Yes, John, it is a championship tag-team belt - unfinished but close to completion - sadly, I have to admit, cousin Luke currently makes nicer ones than me... but I'm working on 'em. The heraldry is my own 'pedigree' (it is nice to know where you came from - and best not to lose sight of it either!) but I do several re-enactment / living history events each year both as a leathergoods trader and as a participant. Most of my business comes from my website www.barefootleather.co.uk Ray

-

I guess that was a seal of approval then. LOL Thanks guys. Like I said, I know I need a bigger workspace but I can't afford to rent anywhere. UK rents are extortionate. Hey LadyKahu. it is a workshop - milk goes sour in a workshop the minute you turn your back... I gave up buying the stuff in the end. No, Jonathan, it wasn't just for you LOL. But I'm realy looking forward to your visit. At least you know what to expect... or do you? LOL. P.S. Good luck with the thesis - enjoy academia while you can. Thanks for the kind words, Dave. Okay, it is small but perfectly formed! R.

-

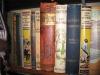

All of the books in my collection are family reading, John. Nothing grubby or untoward at all. Just the titles make them stand out. Glad you had a chuckle, Wyoming Slick. It kinda helps the day along. LOL Ray

-

I couldn't agree more, Dave. It is a real pain in the aspidistra when I see all that money walking past at a show but I can't afford the technology to snatch it. The most affordable deal I have found so far is a company suggested by the National Federation of Market Traders. I'm sure a quick web search will turn up their name 'cos I can't remember it right now. Ray

-

Having complained that I didn't have enough space in my workshop I decided to do something about it and moved the whole thing to a different room and re-organised the space I had available. Several people have asked me to post pics of my new workshop space so here it is. There are probably far too many pictures but I guess if you don't want to see 'em you won't look! Enjoy, but please tell me what I could have done differently/better/more efficiently - that way we all have something to talk about! LOL I'm happy to hear all suggestions. Thanks for looking. Ray

-

I thought long and hard about who I might offend with this post but thought it was probably worth it for the laughs. My hobby is a bit odd 'cos I collect old books with titles that are, shall we say, 'different' Look at the book titles closely and see what you think. All are genuine books published in the 19th and 20th century. Funny how language changes isn't it? Sorry if we don't share a sense of humour, just be grateful we aren't all the same! LOL Ray

-

You won't regret the purchase, Chillibean. I've really enjoyed that book. Great pictures! Ray

-

Great film, Jack. Many thanks. Ray

-

Thanks for the suggestions, TigerPal. I have made several tassels today and think I've cracked the method. The trick seems to be to glue the roll of leather as you roll it around whatever is used as a central core or ''lace' - in my case a bit of braided 'bolo' tie leather. It has to be left for the glue to harden before attempting to put stitches in it. At least, that is the way i'm doing it for now LOL Cheers, Ray

-

Can anyone, please, give me some clues on the best or easiest way to make neat leather tassels - the sort of thing that might be used to decorate sporrans or leather brogue style shoes? I have added a picture to explain the sort of thing I'm looking for - but if you have a better looking style I'd really appreciate hearing about it. Hope you guys can help! Cheers, Ray

-

Mine hid all the bobbins for my harness machine during my workshop move... they gave them back the minute I shelled out a fortune for 6 new ones. sigh... They still have more stuff than I want to think about including my copy of Purses in Pieces that I need for a job. Is there no end to their nonsense? Ray

-

I'd agree with Luke all the way here, Hilly. My experience of hair on deer hide has been pretty poor at best. Nice looking to start with, but it sheds like there is no tomorrow... Same thing with hair on reindeer (even worse) and goat skin. In addition the hair on goatskin brings some people (like ME) out in unbelievable allergies. Sniff sniff. Had you thought of using some nice soft rabbit skins? Bunny in a box might be a winner... first catch your rabbits! LOL Ray

-

Nice work. The antlers look great! Ray

-

Art, I already have both of Chuck's videos - both are excellent and informative. Like you, I'd like to see a beading technique video - Hey, I'd even pay money for one! I've also earmarked a couple of the Will Ghormley patterns and, when the money comes to hand... Charlie, I'll go through the book for you this weekend and see what can be found. I'd planned to spend a bit of time researching gun leather so this would be a pleasure. Ray