Coeta

Members-

Posts

36 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Southafrica

LW Info

-

Leatherwork Specialty

None

-

Interested in learning about

Sewing canvas, awning,trampolines

Recent Profile Visitors

1,429 profile views

Coeta's Achievements

Member (2/4)

-

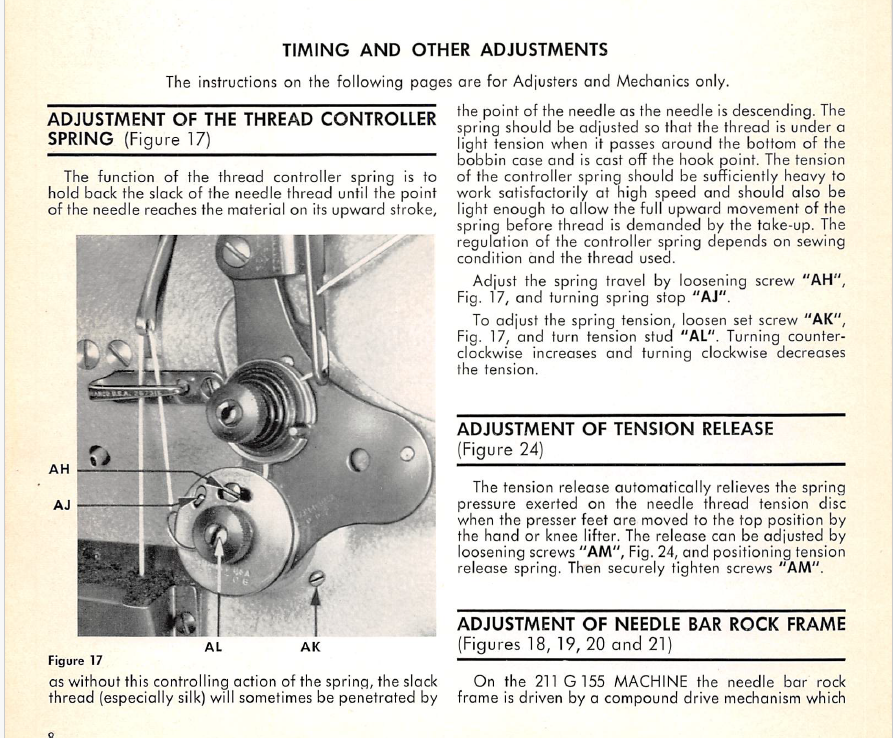

Just adding some images, I was always wondering why the stitches are having a slight stance to the left and not perfectly vertical aligned as can be seen for the rows not marked with arrow. The row with the arrow was my last test run to have the bottom and top thread nicely interlocked took me a while to get it fixed.

-

Managed to get old fossil to work...needlebar height was not spoton ...adjusted the tension and the stitches locked nicely

-

-

thanx for the detailed response I am absolutely sure I have thread it correctly, I think the issue is with the take up spring just after it goes through the tension discs , I dont know how stiff it must be, with it been very stiff it still is not enough to pull the thread back through the material to straighten out the loop on the bottom of throat . I have used the following link as a guide but as said the tension is much stiffer https://www.youtube.com/watch?v=uQ0i2f-q0i4&t=185s

-

Well it's time again to resurrect the old baby .......3 years down the line and it was never used, a new project is on hand, it looks like if i need to start from the beginning setting it up, what I found problematic is with the tension of the thread something is not correct as it brakes the thread Turning the handwheel to check the timing the hook is passing the needle and is picking up the loop when the needle goes up, turning the handwheel further so that that the hook comes around a second time the thread still has the loop formed at the bottom of the thread plate this the thread has not been tensioned by the tensioner while the needle goes up, I have adjusted the spring so that its very tight but still not working, I might have to struggle a while before I would get it to work again. Any tips as this was used 3 years ago....

-

Got it fixed but then I adjusted the pressure foot height as I was working with thick leather, then it did sticth anymore doesnot pick up the stitches, so I guess i did not tighten the gear screws enough..at least I know where to fiddle now

-

Also checking on the parts list for the hook pinion gear, I noticed that there is thrust washer present 224022, that is the part that is missing where I have lifted up the lower bush to take up the free play.

-

I will check out the case opener as that is the only thing I have not really checked, just eye balled it, I can also confirm that there is no up or down movement in the hook and this cannot be adjusted on the 166 As for the statement: Be Sure Hook Driving Gears are Correctly Set with relation to the face of the hook saddle. Use .008" Shim". I'm imagining we use a .008" shim between the gear and the saddle to set end-play? It's not clear from the manual. I am not understanding this .... Edit...got a more english version of the manual and it's more clear now, checking the distance I can confirm it's much more than 1mm I will need to fix this...

-

Some setting on my timing is not correct , I struggle a bit finding what might be wrong when turning the wheel by hand I got about 3 stitches then it is slicing/separating the thread when the hook passes the scarf of the needle, watching it from the bottom during the upward motion the thread is creating a little loop on the bottom of the material where the hook catches it again when turning past it thus creating tremendous strain and breaks the thread, As the needle bar does not have marks on it I have set it up as described in the manual, with the needle to hook timing, Might it be the tension mechanism that does not take up the slack of the thread, ,,,Oh well it's patience that keeps playing a big roll here to get what the problem might be I do have one question though regarding the upward free play of the little gear below the hook , the hook pushes through a gear (the small one) then it runs on a driving gear (the big one), Referring to the fitment of the small gear it pushes through a brass bush that gets hold with a little screw , how far must that brass bush be pressed in the housing as i have noticed that the small gear have some upward free play of 1mm if you turn the handwheel forwards or backwards, thus it's causing a delay in the point of the hook timing to the needle to be in the centre line of the needle. I have loosened up this lock screw and lifted that brass bush upwards until there is no upward or downward freeplay for the small gear _ did I do the correct thing here or are there supposed to be any shims inserted on the top or bottom of the small gear to take up the freeplay, or must that bush be fully pressed down with the free play applicable Referring to gear - point nr 5

-

Resurrecting an old thread, Yep this was the last time I have used the machine, and in the mean time we have moved to another house and so the machine was neglected and stowed in the garage on the floor deep under the dust and the metal parts got some surface rust again, and sadly the tension mechanism got damaged, cant remember if I left it still working or not, So I have to work through this thread again to get the old girl operational again, setting the timing checking everything...

-

post some images of tubular straps done

- 11 replies

-

- shoemaking

- leather

-

(and 1 more)

Tagged with:

-

I would also guess there is too much friction/stiffness on the thread at the needle hole as Constabulary suggested... I had similar experience when I used that sticky double sided tape when preparing to sew the material together.. when I sewed I had endless trouble with the thread not been pulled up back quick enough by the regulator spring no matter how I adjusted it...that double sided tape was just to sticky for the thread to be pulled back quick enough....after I removed that tape I had no issues... With your experience you should be able to figure it out....

-

Horween bifold

Coeta replied to thefanninator's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

F#$@n nice!! -

wow this is looking very nice...keep it up very nice to some fellow's got skills

-

Uwe...what motor is set up with this Juki? This looks like a very nice compact portable system.

.jpeg.fd913572d771d994d73675ce698bcbd3.jpeg)