-

Posts

328 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Shelly

-

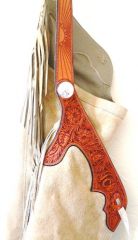

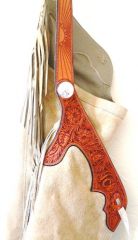

MJ Liggett Saddlery - Chaps (Floral, etc)

Images added to a gallery album owned by Shelly in Our Leatherwork Galleries

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

© © leatherworker.net

-

-

From the album: MJ Liggett Saddlery - Chaps (Floral, etc)

© © leatherworker.net

-

I always order 1/4 extra in the wood for a finished hard seat - need 1/2 to a full inch to accomodate a reining/pleasure saddle that has a padded seat/buildup on the swell. The padded seats always shorten the finished length alot. I always ask my customers what they are currently riding, do they want it shorter/longer, is it padded/hard seat, and take that into account when we are discussing what they want in the new saddle. I will also tell the tree maker that the seat needs to be '---' inches, when they are finished. It makes a difference in the wood, and if they fiberglass the tree or rawhide it...

-

Tooled Purse

Shelly replied to hidepounder's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Bob - Beautiful work, as always - just when we think you have reached the top, you surpass yourself!! I do have a few questions - you mentioned that you used #69 nylon thread - what machine are you sewing it on - only the interior, or all parts, including the outside panels? How many stitches per inch? I would love to make a trip to AZ and come learn something from you! Wish I still lived there sometimes...I was raised in the Phoenix area, and moved to NM in 1986, then to OK for 3 years, in 1995, now in Mineral Wells, since 1998....this area reminds me more of AZ than any other, just don't have the saguaros, barrel cacti, etc - we do have some cactus. Lots more humidity, so that's the trade-off for having grass! Thanks! Shelly -

This is how I do it, and it generally works out fine. Soak the rawhide in warm water, checking often, until it has the feeling of 10 min spagetti, not quite soft all the way thru, and definitely not 'raggy'. Hang up until it isn't dripping any longer. Here is the part that I think makes a difference - you need to use something that holds in the humidity, but doesn't condensate on the inside - I had the same issue with bagging rawhide, as some areas of the hide will soak more or less thruout when you are soaking it. What happens is that the bag is touching the hide in places, and as the condensation beads on the inside of the bag, it concentrates in only the spots that it touches the hide, leaving it 'rubbery'. Best solutions I've seen are a raised platform humidifier - can be a plastic box with a tight lid - some people use rocks in the bottom of a plastic bin, add a little water, and have a stainless steel grate above to lay the hide on, then will seal it for 24 hrs or so. This holds in the humidity and helps the hide to even out and case completely and evenly. This also can be done with leather that you're going to carve/tool, although I'm usually more in a hurry in that regard, and end up 'quick casing' for leather! Anyway, what I use has been the best for me - I purchased two of the big, round tupperware pie holders, on ebay. I think they are at least 14" or 16" - I will do the above with the rawhide, and then lay my coils in the tupperware container, on top of a double layer of paper towel. Another double layer of towels on top, close it up, and let it sit for 25 hrs or so, checking it a few times. Should work - I should mention that I use hide from Bill Confer at Tejas Industries in Hereford, TX. He sends it already cut in a circle, or full hide, whatever you want. But, time is valuable to me, and he has the best hide available, so I get it cut in the circle, and cut my braiding strings from that.

-

Beautiful work, as always, Steve!!

-

Thanks for all the compliments - there's always something I wish I'd done better on them - best part of it is the calls and emails I get back from the customers - don't figure I'll ever get rich doing this, but I never actually got into it to become 'rich'....at least, not in the monetary sense! Of course, those warm, fuzzy feelings don't always pay the bills.... Attached is a pair of leggings made for a recent customer as well....not sure if I put these up before...?

-

This on a Bob Marshall - 8 1/2" BW front

-

I figured he was big enough to be a JRT - I raise Toy Fox Terriers - attached is a pic of my main stud dog - AKC CH/UKC GRCH Patrick's Strike Up The Band. My girls are al tri-color, and I get puppies in both tri and W/T. My shop mascot is an Eclectus Parrot - used to have a female squirrel, but she passed away from old age. My mascot, Ziva, was hatched on May 1st, 2010, so isn't talking yet, but she loves to watch me stitch, and work, from the top of her cage or on my shoulder. If I am working on something I don't want her messing in/with - she goes back in the cage for a break, and gets to come out later!

-

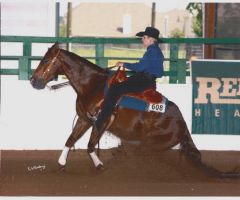

This cutter was pretty basic - customer is a trainer in Canada...he called to report that he loves it, fits his horses well, and rides great! I love happy customers!!

-

This cutter was fun - Customer got it, unboxed, went to a cutting, rode it the night before he showed, and then marked a personal best of 75 the next day! I was his most favorite Texan the next day, so he said when he got me on the phone to report back on how he liked his saddle! Loves it!!

-

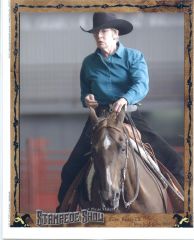

Here are a few pix of recent saddles done and gone...! Customers love them - I've included one pic of the saddle being ridden for the first time - wascustom fit for both the horse and the customer. This reining saddle is the first of three...

-

I got it in 1997 - much of it still has the little tags on the stock, with notations as to quality, etc, in Rose's handwriting, I'm sure. I did some work for the man that gave it to me...he is also passed away, not long after that. Luis used sewing machine belting - this is the rounded stuff you can get on spools. I have about 3 different sizes, with the smallest being what he used in the braided headstalls...I'll try to post a pic of it in the next few days. Have lots of repair work to get out at the moment...