-

Posts

165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mixmkr

-

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

-

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

Thanks Eric, ...don't want to hi-jack this thread, but I've learned a lot too. Maybe some pics of a 45 degree binder when things slow down :-D Good info, thx again. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

45 degree ....oh yeah. I'll have to think out how to get the straight line to "swing" into a 45, if that's even possible. Double hinges for sure. Great tip. Thanks!!! -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

The only negative to the inline swing away though is if you're binding the inside of smaller curves, trying to shove the material up against the binder. Outside curves are a piece of cake.. My right angle binder didn't like stiffer bindings though, as the binding get "inverted" going thru that type. The swing away makes life easy though is too many ways. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

It has the same two holes as my JUKI in the lower right of your picture. Basically identical bed. I believe they were metric too, so you'll need a hardware store that sells beyond the typical screws..... but a big box store ought to have them too. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

By the way...I did grind on my swing away in the picture above, and it isn't like it's really hard stainless steel. I had to widen the one slot to match the holes in the bed of my JUKI. A little dremel did it really easily. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

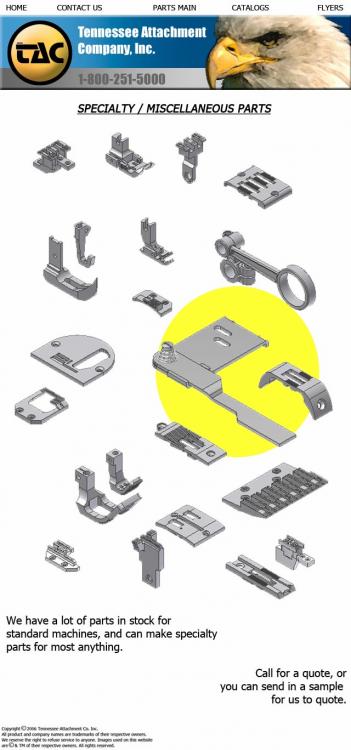

I agree about last century's website.... but they DO have they swing away that I have. No reference of part number but it's on this page:... in the middle on the right side http://www.tennattachment.com/SPECIALTY, MISCELLANEOUS PARTS PAGE.html -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

wherever you have screw holes in your machine bed, you should be able to use them. Just use some paper to make a template and have someone just cut it out of some 1/8 "" aluminum or whatever. I don't think it would be premature to order the Sailrite binder if you haven't..as that would actually allow making the design all that much easier. I just had this bracket, but even a "T" square metal ruler would have worked, cut to size. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

That bracket came with my machine and had my right angle binder on it originally. Regrettably I haven't seen another like it, but since the Sailrite is swing away, you could just make one out of aluminum that doesn't swing. Make an "L" bracket," , so to speak and let the Sailrite do the swinging. As an offshoot, I was ordering some stuff some Sailrite yesterday and had some questions. I was able to talk to Matt Grant (VP) and he was extremely helpful in answering some questions, as have been others in the "chat" too.. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

-

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

-

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

As you can see, my "first" swing away bracket puts the mounting holes over the bobbin plate, which is where I then attached the Sailrite binder. Double swing away!! The inline works SO much better, but of course you can't do inside curves as easy. I've only got one screw holding the first bracket, and need to drill another in the bracket to match what my machine bed has. But the one screw has held for a bit now. -

How to attach a binder to a Singer 111W155?

mixmkr replied to Willie0's topic in Leather Sewing Machines

I've got a Sailrite swing away, as my right angle binder wasn't liking the stiffer Sunbrella running thru it. I had a bracket and ended up attaching the Sailrite to that bracket. The Sailrite binder is pretty flexible as to where you mount it, as you can adjust it over a fairly wide range. I think you just have to make up something that works or get a bobbin plate that you can screw holes into. -

Juki DNU-241, Consew 206rb, request for advice

mixmkr replied to pattyharrington's topic in Leather Sewing Machines

To clarify...am I off base to say that initially the Singer 111w155 was the Grandad and all others followed along with their various adaptations with JUKI being one of the first (and appearing to start the trend in that style machine)? Such as the LU562 and onwards. Granted those are older technology and (as a guess) probably aren't in the same league as JUKI's 1508.... but a continuation of the Singer model. And the various competitors/offshoots from Tacsew to Consew, etc jumped in along the way?? The DNU241 can trace its' roots back to the Singer, as does the 206RB.- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Juki DNU-241, Consew 206rb, request for advice

mixmkr replied to pattyharrington's topic in Leather Sewing Machines

I'm just a "reader" but I'm under the impression (not regarding the Singer 111), the JUKI is the "mold" and the Consew and others are the replicants. The Consew if not mistaken is Chinese made while most of the "better" JUKIs are still made in Japan at a slightly higher quality level. I might also think the JUKI will hold its' value better too as well. Lots of Consews sold too. But if someone told me :JUKI" was "brand snobbery" (!!) I"d listen too. ;-D- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Juki DNU-241, Consew 206rb, request for advice

mixmkr replied to pattyharrington's topic in Leather Sewing Machines

I"d also try different needle brands and sizes or even thread for your shredding and breaking problems. I'm beginning to think it is like car wax.... what works with one isn't the best for another. Cheap thread is just that too...I think.- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Juki DNU-241, Consew 206rb, request for advice

mixmkr replied to pattyharrington's topic in Leather Sewing Machines

I'm going to watch this thread like a hawk, as I feel I can totally sympathize with your situation. I use a JUKI LU562, a predecessor of your 241. If I'm not mistaken, the 241 replaced the 562/3 with a short span and then the 1541 ( and 1508 series came out. )Yours being the horizontal axis loading bobbin...isn't it ???, where as the 562/3 and 1508 are top loading vertical axis. I have a good friend who uses a DNU 241. That said, I'm not an expert and will probably get laughed at by those in the know, around here....but have some comments and opinions. Any rate, the friend says the JUKI is a great machine but a little fussy. I interpret that to mean he has his issues too, but also has run lbs of thread thru his machine, enough to replace guides etc because of wear. We both use 138 Tenara thread which is super slippery, so my tension is soooo tight you could squeeze a seed out of an uncut watermelon. But currently it is sewing good. I go in reverse and hold my breath, so I don't get tangles. But fortunately those are typically lock stitches at the beginning or end. I tend to think the Consew is probably a step down But it is extremely popular as you know. Your JUKI probably sells for $1000 more for sure. But that isn't the issue or selling point. I tend to think the 207 thread is at or slightly exceeding your machine limits. At that point I might "believe" the quality, brand and type of thread become more important. I've also (being lazy) stuck some 92 bobbins in with the 138 on top, and my machine seemed to like it. Maybe stick your 138 on the bottom with your heavier on top. Just a guess...and also probably not 100% desired. I'm sure you've experimented but routing your top thread a tad different.... I also put my spools about 6 feet away to help with twists, etc. Whether it helps or not, I'll just say it seems like it. Lastly, I tend to not think too highly of the tech as there are too many of these machines running great, out and about. He should trade UP to you would be my opinion. Look at used pricing and I think you'll agree. A NEW Consew complete will sell for about what your 241 sells for used much of the time. Yeah.... I see all these beginners on their plastic Brother machines sewing like wildcats, but they're not doing the tough stuff. I think it is just finding that sweet spot. IF you change your types of sewing a lot,.... that might be a hidden issue. But if your sewing is the same consistent number of layers, material and thread... I think once you find the groove, your JUKI should take off. Best of luck and again...just some minor experienced opinions.- 24 replies

-

- juki

- consew 206rb

-

(and 1 more)

Tagged with:

-

Could it be said a vertical axis, top loading bobbin is more expensive (better???) than a horizontal? A Juki 1508 vs Juki 1541 for example. Who's the best dealer to drive to from Western Kentucky? StL, Nashville, Memphis potentially in driving range. Looking to upgrade from my LU562 or just hang on to my machine?? The small bobbins are a hassle. And I've gotten the "fear" of needle breaking, reading around here, with the !508NH and the longer needle system. If I stayed with the 135x17 needle... can that be used on the 1508NH or just get the 1508N then?... or stop fussin!!!

-

Stick a heat gun on that Locktite. Makes a big difference.

-

I would think you could make your own timing marks. Not an issue really, I'd think. Can't comment on Chinese clones though. I'd be just as concerned about what to do, should the machine have issues. Who would be responsible. The value or a trusted dealer is definitely worth some $$

-

Edge Guide for Consew 225 (and clones)

mixmkr replied to KeithHideWorks's topic in Leather Sewing Machines

now that's nice -

manual presser foot lift on JUKI LU 562/3

mixmkr replied to mixmkr's topic in Leather Sewing Machines

Or swinging material getting ready to run over a thick seam, etc. Seems to be the "more option choice"....or maybe not! Keith...your setup seems backwards. -

Machine help- too much good info- please.

mixmkr replied to Brad2017's topic in Leather Sewing Machines

Aren't the Fabricator, 206RB and the JUKI all unison/triple feed? You're the expert, but those are all popular marine machines and I have been led to believe the walking foot, needle feed (or triple feed or unison feed) is most desired. Also typically, I think many use the flat footed presser feet, as I do especially when sewing in clear vinyl windows. Those grooved feet definitely leave their mark on the clear vinyl like pigs running thru a putting green. Then I (and I think others) just leave the smooth feet on, unless there are problems feeding/pulling material. Am I getting my definitions mixed up?? :-D -

Edge Guide for Consew 225 (and clones)

mixmkr replied to KeithHideWorks's topic in Leather Sewing Machines

Dang... that's a mighty big wall. Who's going to pay for it? ;-D -

Machine help- too much good info- please.

mixmkr replied to Brad2017's topic in Leather Sewing Machines

The Sailrite Fabricator is new in their lineup, replacing their Sailrite 111. Supposedly has some upgrades and has only been out for about a couple weeks as you mentioned.... hence no reviews yet.. Looking at the specs, seems the presser foot clearance is slightly less than the JUKI or Consew, but Sailrite's service is stellar and that is probably a fine machine for medium leatherwork. I only do marine canvas, and I'd be comfortable with it for sure but use a JUKI LU562. I'm fairly new to this as well...so.... :-) I order quite a bit from Sailrite for my marine supplies, and they're extremely fast and accurate. They have a live chat on their website too. All that said, I might personally lean towards the JUKI and then the Consew...and then the Sailrite. But I'd be happy with any of those actually. Edit... I don't know who makes the Fabrciator, except I believe it is made in China. But Sailrite will go over the machine before it is shipped out. I believe the Consew is made in China as well and the JUKI maybe still in Japan. Again, I'm not the expert, but always good for opinions!