-

Posts

165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mixmkr

-

Scott...anything else besides bobbin size that made you smile? This is NOT the "N" or "NH"...I think maybe around 10 yrs old??

-

Seems like a good price...realize it's Ebay...and posting might help attract other bidders of course.... but this machine has been listed a couple times now. Owner answered my question that it was a backup, they had a full time maint person at their facility, etc. Looks a tad worn obviously on the reverse lever, etc for "light use"... But I could use a larger bobbin and keep (or I guess sell) my LU562. Using 138 thread, the bobbins run out quick. My LU 562 is in great shape and I just had a tech totally go over it and give it a "thumbs up". Is this just an average price.....'cause I see this model usually selling for $500+ or more. The "N" or "NH" I'm led to believe just can sew a tad thicker, requiring the longer needle, which is potentially prone to break easier?? IOW sewing thicker, but softer leather would be best?? I'd pick this up in a heartbeat if this was a good, safe buy. Again...it's Ebay, but the price seems almost 1/2. Supposedly this is just the LU563 "newer model/upgrade" ?? What am I missing? http://www.ebay.com/itm/291999523998?_trksid=p2060778.m1438.l2649&ssPageName=STRK%3AMEBIDX%3AIT

-

Anyone Tried this Speed Reducer?

mixmkr replied to KeithHideWorks's topic in Leather Sewing Machines

the speed reducer in that video is hooked up to a clutch style motor. Not sure why your servo is not allowing slow enough speeds at its' lowest setting, unless you have a larger pulley on the motor. Typically, I think you might see 50-60mm pulleys in use for super slow speeds. Any rate, a different servo motor is definitely less expensive than the speed reducer, usually costing a good amount less than $200 for a quality servo motor. I've bought two servos in the last couple years (both SewQuiet Reliable brand) and they have been fine. Albeit the settings are on the motor, so you have to reach underneath the table, but it isn't that far a reach actually and easy to see. -

easily without breaking the bank?

-

That price is yowza!! A machine shop could fabricate one for less, I'd think too.

- 11 replies

-

Uwe, I don't have the words to thank you...and such an immediate reply COMPLETE with video. The bobbin case open on the JUKI seems to be a bit touchy, but after getting it screwed just right, the stitches are now perfect again. I need to take you out to dinner or whatever I can do. Just to let you know, you're putting smiles on my face. Thanks soooo much! (and what I've learned from you and these forums has been nothing short of exceptional)

-

So...following the Navy manual, (and Uwe's vids) I felt good about all the adjustments I was able to do. Set timing, presser foot height, centered needle (verified) in feed dog, presser foot lift and relative presser foot lift... all went well. Sewing great. So...after running a bobbin or two thru test material, of course I put a "job" on the machine and the sucker was breaking upper thread after a couple of stitches. Cleaned the bobbin case out, lubed sparingly...etc. My problem appears to be the upper thread when traveling around the bobbin case, is not easily making it over the little notch in the bobbin case, that fits into/under the needle plate. There is a little slop in the notch and I'm under the impression the stud protruding out of the bobbin case kinda rides against the notch on the side away from the operator.. Guessing there's about 1/16" slop in the notch, so the bobbin case isn't just held really firm. Also under the impression this is normal. But why the thread is not clearing over this notch, I don't understand. Being new enough to all this, I'm presuming it has to as well (dumb question??) I'm learning bunches, but when one problem is solved, the next one gets in line. What's the deal with the upper thread catching (and then of course breaking) on this little stud that sticks out the side of the case? btw...Uwe...if reading this... routing the slippery thread around that pin on the first upper tension disk seems to be helping to keep the thread between those disks and not popping out.

-

you guys are a big help... will sleep on it for now. Uwe...I have rotated my 3 hole threader, 90 degrees like you've said. That helped, but the threader has a flat side, so the set screw doesn't really like trying to hold it other than a vertical position. I'll keep experimenting. Also realize the auto tensioner is just for pulling material out too. Yeah...a conveinence. Floyd...yeah...92 is probably ok, but 138 is a preference. ...ONLY because I see it a lot from other canvas guys. and yes...left twist thread for sure... Don't think I own anything else except some mono or nylon junk. I've learned a lot today... you guys are my only advice and what I can read... so it gets frustrating sometimes and I tinker more than I sew. Need to make that a much better ratio

-

two layers of Sunbrella, a layer of Velcro, using Tenara #138 equivalent and tried needles from #14 up to 20...different bobbins..the usual drill My problems is like Uwe noted in my one picture, the thread doesn't go between the tension disks....or stay there when sewing unless the tension is cranked... Then I'll break upper threads.... loosen it up, birds nest underneath. The lighter Tenara works better...sometimes... Hence asking about the Solarfix. I can't use Dacron thread on my projects. I almost bought a 1508 off Ebay today, but was gun shy. Only $1150 for the shootin match. Need to see what the venders here might do... and maybe take my LU562 in trade? I can't afford a down day like today. Yeah...tomorrow's another day... $0 for today...

-

yeah...that's a newer upper tension assembly. I switched back to my old one. Went I started using PTFE thread, I was having huge problems and thought I'd get a new one. Today has been horrible. Tinkering all day while the sewing jobs pile up. Machine is sewing like crap. Will let a local sewing tech look at it... otherwise, I'm getting something new(er).

-

btw....Your vids give me the "courage" to wander into the forest! ;-)

-

thx again Uwe, Sorry about turning unknown screws!!. Yes I saw it was just a set screw, but I'll always count rotations and such too (coming from working on paper folding machines, inserters...of the era) and yes...the thread is just "laying" on the upper tension disks... it's #138 PTFE thread...so I have to pull it down because the thread is so slippery and have a heavier than normal tension, it seems. It seems that pin is not doing its' job, so will investigate further. Your vid is an involved procedure, but shows what's happening. I'll check it out more, but not sure I want to dismantle as much as you have done in the video! I appreciate all the help as of recent. thx so much

-

As noted in the pictures.....what does this set screw do? ...and is it related to the little pin that is suppose to plunge out and open the disks on the upper tension guide? Asking because the screw seems to have no effect and my upper tension isn't releasing at times, like I'm believing it should... like with the presser feet up, etc.

-

Floyd...yeah I got some OEM parts...I believe, but couldn't order any off our vendors today and figured it was a small item too. Those feet in the pics are for binding, but do have some wicked teeth. I don't use them much, but they're good for zipper feet, with the outside foot, missing one of the feet. Generally I use the standard smooth feet. Those do look like jaws! btw...I can't use them on the clear vinyl windows for sure. Like driving a tractor thru mud, with the tracks.

-

I see I can buy a set pretty cheap...$13 or so... and have the option of a slotted feed dog or just s single hole. I have a single hole in my binder, taller feed dog now, so I guess it doesn't really matter.....right?

-

thx Uew,... I think I just discovered that, as I could not lower it sufficiently enough to make things work. Unfortunately I don't find a shorter bottom feed dog in my collection of junk either, so will order. Probably unrelated, but I was getting huge loops from my upper thread, on the lower side. I messed and messed with stuff, (trying the learn and potentially making it worse!!)....adjusting heights, pressure, etc. BAD stiches. So....I ended up putting back in the taller binder plate and the thread stiches went back to good again. I don't see how that's related, even if I was to get "close" lowering my middle feed dog (per your video). Will order the regular set, so I get "matching" plate and dog, I suppose. They're not much. But I could use that extra space under the feet without the binding plate. You guys have helped me immensely. I can't thank enough. BTW, I'm using 138 equivalent PTFE Gore Tenara thread, which is pretty slippery stuff....to throw that all in the equation.

-

Eric, you've been a huge help and I've learned a lot today. Floyd, you too as always. (we need to visit someday!) Happy New Years guys Thanks again.

-

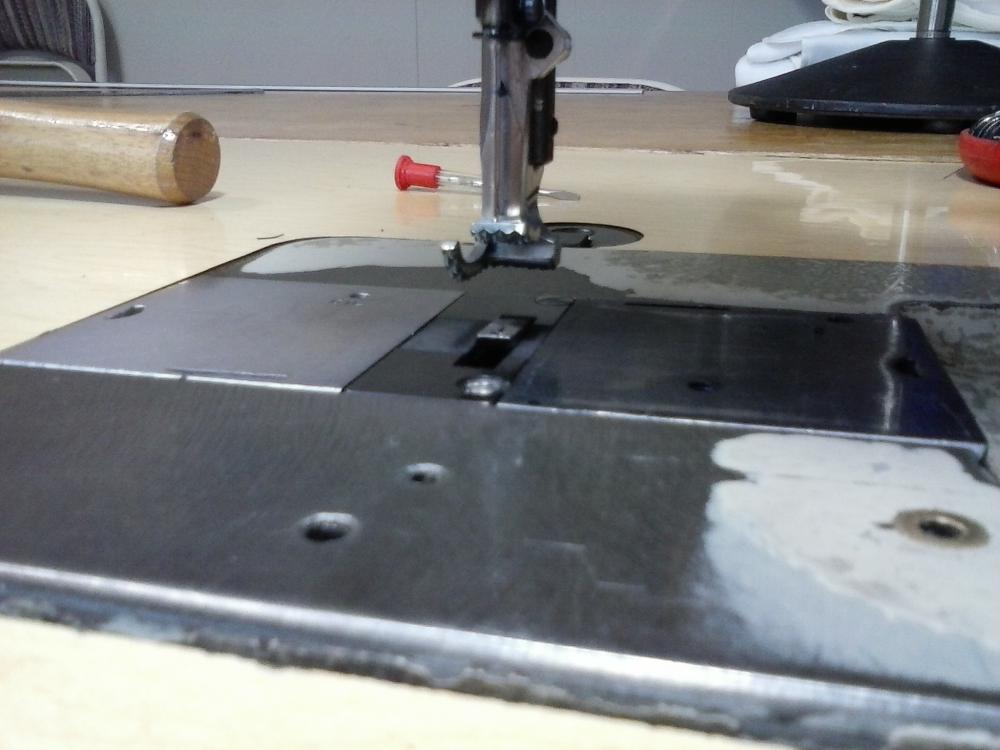

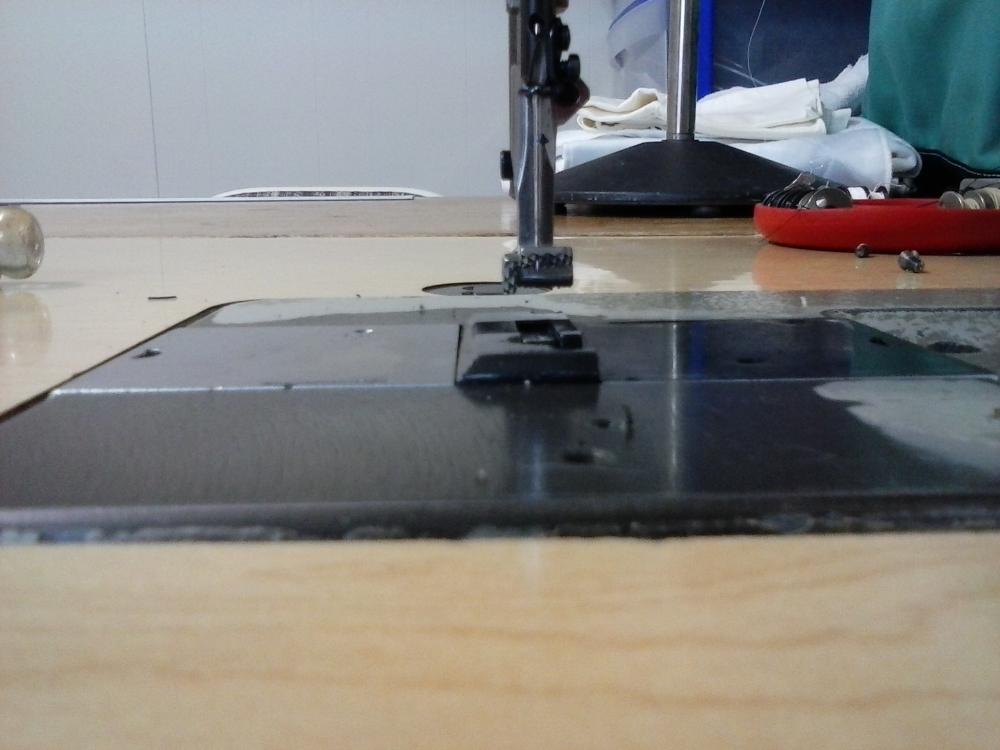

Wow...you guys are extremely helpful. My lucky day too! I did look in my "extra parts" I got with the machine...and an almost new looking flush plate !!!! I agree Floyd...no need to switch back and forth (I would think???) . What is the purpose of the binder plate? Just get it up a tad?? All this said... I guess I need to lower my bottom presser foot now. This pics show the lowest it goes, as it was set good (tooth fully exposed when raised) with the binder plate. I'm too new at this !!

-

Is this normal?? Seems the needle plate should be flush, not to mention giving me a slight more clearance under the presser feet. As you can see, it has been previously ground out as well for my binder feeder to slide up closely too. A flush plate would eliminate that need for the grinding out section as well. And of course, I'd prefer flush, so I could feel my work underneath, without dealing with the little raised portion. If so...I suppose the lower feed dog would need to be lowered, but the needle/hook timing would remain the same? I guess the upper presser feet might need some adjustment then too. ....yes...I'm fairly new to this, but have to learn because it's now my profession! ;-O

-

I use the SewQuiet 5000 and now the 6000 on two different machines. Both fine with the smaller pulley...I think it's either 50 or 60 mm. There's another recent thread In which I asked about them too....being new to them as well. They work good and seem as good as any with their specs.

-

yowza...!!! looked at some of Miami's pricing....ouch . Sometimes more than twice what I'm paying wholesale

-

I can't figure out how to order from Quality threads... no pricing on their site either. I guess I need to contact them and open an account or something. I remember seeing this site, googling Solarfix thread, in the past... but Miami is the only place I could order instantly as a "guest". Quality I do see has a $100 min order, which is OK too.

-

Floyd...I pretty much only do the outside canvas and it would get me a bad rap to use the Poly.. Nylon only for interior cushions etc. I have about 20 spools of 92 and 138 Poly in assorted colors, but I don't want customers complaining about stitch jobs in 3 years...like I'm sometimes seeing with the Poly thread. It's also a selling point to use the PTFE thread as well. When I use an amount I charge $15/bobbin anyway...otherwise I just mark up the job. With a $2500 canvas job, using $50 worth of PTFE thread only makes sense. That said, I'm getting an amount of re-stitch jobs too, which is helping me learn the marine canvas techniques as well. I need to come your way and shoot the breeze. There's two other competitors in the lakes area...one I don't really know and the other I've known since he moved here 15 years ago. He is very good, but isn't that open to helping me out, even though there is enough business for another 6 canvas guys in the area. Anyrate...starting to babble in this thread...but I guess that's ok too... at least sewing related! Happy New Years.... be safe and don't stick yerself with a needle!

-

hey brmax... Where are you getting your Solarfix? I don't think they make the 138 equivalent anymore and just the 92. I'm trying to basically stick to one thread at this point as my work isn't all that varied. I started out with the 92 equivalent Tenara...and it's OK. The heavy Tenara sews better and seems much stronger. Not sure if I really need that for the biminis and such..but that's what I'm seeing other custom canvas projects for the most part. The 92 Tenara "hides" better as it is more clear colored (using the white) and in colors like grey, beige, etc...looks good. The heavy 138 Tenara in white is VERY visible....and very white. The only place I'm seeing for the Solarfix is Miami Thread. Have you tried Tenara? ...cause I hear the Solarfix is much easier to use. I tried the Profilein (sp?) stuff from Sailrite (it's a PTFE thread too) and it is only 92 weight equivalent...but it didn't like it as much.... albeit I haven't used it much. btw...I think your 1508NH is in my plans too. Sell my unused stuff and the JUKI LU562.... should about cover the cost. I just need the head.

-

oh...OK... I guess you're original thinking was I had the belt tension too tight then?? Seems OK actually...proabably about that 1". The motors just "wimper" when I hit a 12 layer Sunbrella seam ( I usually pound the seam with my leather hammer to flatten it to fit under the feet!). That's if I stop JUST before the seam and get ready to make "the jump"! thx again