-

Posts

165 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by mixmkr

-

Uwe, your photos (frame grabs??) and videos are some of the technically best ones I've seen on the internet. Your vids are crystal clear, totally in focus, and the lighting is superb. I dabble in some YouTubes myself, and found that good "daylight" lighting...either natural or bulbs is very important...done "correctly" too.. However, yours take the quality to the next level. At some point, a video on how you DO your videos, explaining some of the technical stuff, like frame rate, lighting, cameras, etc would be EXTREMELY interesting to watch and learn from. Again I only say this because your quality is A+.

Here's the quality I'm getting, using a $300 Canon camcorder at 1080p @ 60 fps and a bunch of daylight bulbs along with using Sony software to sharpen it up and for editing. The background floor lamp is just for "looks".

-

This status update area is a public messaging area, by the way. You'll have to use private messaging if you want to communicate in private.

My technical macro videos are quite different from live action people subjects. My lighting approach may not translate well to your studio sessions.

My camera is a bit more costly than yours, but mainly because I have a good macro lens to get very close to things. I use a Canon 70D with EOS 100mm F2.8 L macro lens, about $2K for the combo. My "video lights" are super cheap in comparison. I use Feit LED shop lights I got at Costco for $25. The tubes are made of plastic and flex a little. I often point my lens between the two tubes to get a cheap ring light of sorts that has almost no shadows.

I always use manual focus when filming technical stuff. With close-up macro photography, depth of field is often very small - sometimes less than a centimeter (1/2") or so of depth is in focus, everything else get super blurry real quick. Sometimes that's useful, sometimes not. To get around that I crank up the ISO sensitivity setting to 6400 or so that I can stop down the aperture to around F/22 to get maximum depth of field so that (most) everything is in focus. The high-ISO video is a little more grainy but the sharpness more than makes up for it. The camera records 30 fps, with 1/30th second shutter speed, at 1920x1080 resolution. I edit in iMovie for the simple stuff.

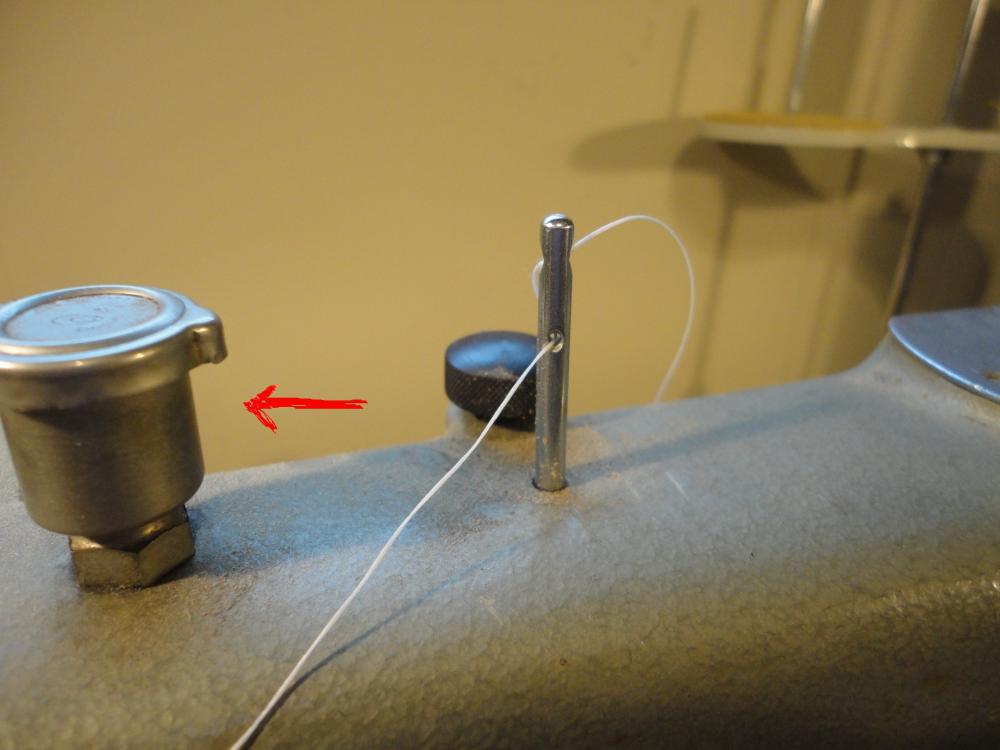

Here are a few behind the scenes photos of my high-tech studio setup

with the Cowboy 4500 ready for its close-up.

with the Cowboy 4500 ready for its close-up.

I used four LED shop lights (one is out of the frame behind me) for the lighting setup. You can see how I splayed one set of plastic tubes apart at the top and point my lens right between it. One light points at the white background to make it bright white.

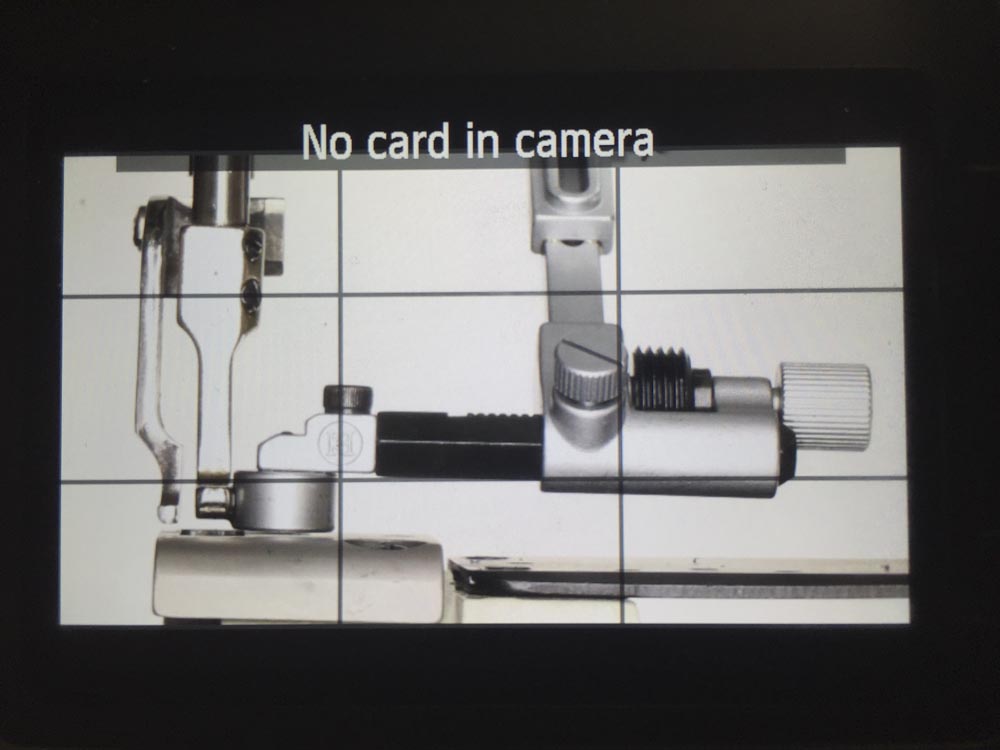

Here's the view from behind the camera:

And here's a close-up of the screen:

-