George1520

Members-

Posts

58 -

Joined

-

Last visited

Recent Profile Visitors

2,752 profile views

George1520's Achievements

Member (2/4)

-

I've been getting 2pt rule from Ameriken. I've talked to them last week and they didn't have any 6pt rule in stock. Is there any other supplier where I can get thicker rule? Thanks

-

Shoe finisher dust collection bag material

George1520 replied to AlizabethThomas's topic in Leather Machinery

Try duda energy fabric or google 1 micron fabric The material on mine is heavy felt fabric. The fleece material is not a bad idea. The nice bags are made out of felt and cheap bags are made out cotton canvas. Rubber doesn't need much dust collection. It is heavy enough that it doesn't make it into the bag. But you definitely need it for leather soles or foam. The bags get pretty nasty. The combination of fresh glue and leather makes the bags like a big discarded tissue full of snot. -

Steel rule die fabrication table

George1520 replied to Ozarksleathersmith's topic in Leather Machinery

That is the idea behind dies used in printing. Cut the pattern in plywood, bend the rule close enough and then hammer the rule in the cut. No screws, the rule is free to move up and down but not sideways. The cut has to be accurate. Most dies are laser cut, but for leather work scroll saw is definitely good enough The other thing is that the die can be made out many smaller pieces of rule not just one continuous piece. . -

SKIVING MACHINE: V-belt drive vs. Direct drive

George1520 replied to Leatherbag's topic in Leather Machinery

What you want is the knife to rotate fast and the feeding stone to rotate slow. Having the option to slow down the feeding stone it will make skiving corners a lot easier. You can buy a regular skiver and add to servo motors. I slowed down the feeding on my skiver with pulleys and it made a big difference but I still wish that I had a skiver with top feeding roller. -

They are not that big. Those machines are made for factories to skive the same part over and over. Better question is why are leather sewing machines so big when all you need is a

-

Steel rule die fabrication table

George1520 replied to Ozarksleathersmith's topic in Leather Machinery

I got some stuff from Ameriken before, they are nice What rule size do you use and what bit for the cnc? I've been using 2pt rule with 2pt scroll saw blades. The other think to consider in choosing a bender is that if you use 6pt rule, you will need the bender that is foot operated. The hand bender is for 2pt rule that is used in printing and you will need be supported by the plywood like in the photo above. It will be really difficult to bend rule thicker than 3 pt with it. The 2 pt rule is sharper, cuts better and it is easier to work with. It took me a while to find a my bendender. They are not cheap and not many around. It will be cheaper to get the dies made. -

Good guess the Pfaff 138 feed dog and plate fit, the problem is that the zig zag on my machine is 9 mm and the 138 is smaller. But the singer 111 presser bar fits and I will have the option to find a presser that will match the current feed dog. Talking about favorite machines. Would you rather have a Singer 457 or 143 over a pfaff 438? I still need to set a zig zag machine that would do a raw edge on leather and spacer mesh.

-

The one I got has domestic zig zag presser welded to an outside Adler foot. Not a very precise welding. Do you know if the the 138 will work? The it looks like the Durkopp uses different presser feet. Are they the same as the Singer 107? I'll try to see if an Singer presser bar is the same dimension. That way I might be able to use Singer 457 feet. So far I'm pretty impressed with the machine.

-

I just got a new/old Pfaff 114 and I'm looking for the manuals. It is not the new version that basically the singer 20u. The one I have is half Singer W 143 and the other half is Pfaff 145. I didn't have any luck finding the manuals on the web. I think they are more popular in Europe than the states. Thanks

-

Frustrated by Consew 199 - Timing Issues

George1520 replied to spotty's topic in Leather Sewing Machines

First fix the tread path. Here is another way from consew to timing a zig zag machine http://www.consew.com/Files/112347/InstructionManuals/175.pdf Different machine but works well. I had some issues timing my 199, skipping stiches and the upper tread tension was out of control. All was good after chancing the feed dog. I still dont know why that caused the problems. -

Anyone wants to get rid of their zig zag machine? I'm looking for a Singer 457 or Pfaff 438 or Juki LZ with at least 6 MM wide zig zag. I also have a couple of machines for sale/trade. Singer w 108 cylinder walking foot and a flat bed wheel driven Pfaff 591 type machine. Both in great shape.

-

For speed control only have two choices the one that has been already mentioned, a dc motor with a brake and the other kind, a step motor that can use a needle positioning. People call them servo motors but they are not. Sewing machine servo motors are huge and bigger much than a clutch motor.

-

Singer 108W20 - My New Binder Setup

George1520 replied to Constabulary's topic in Leather Sewing Machines

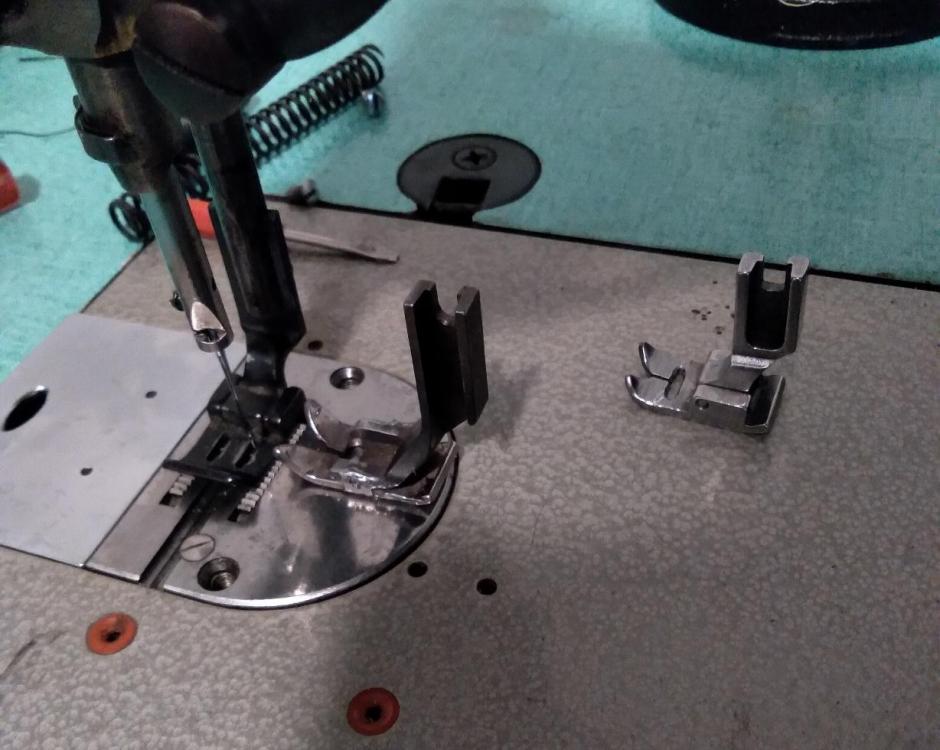

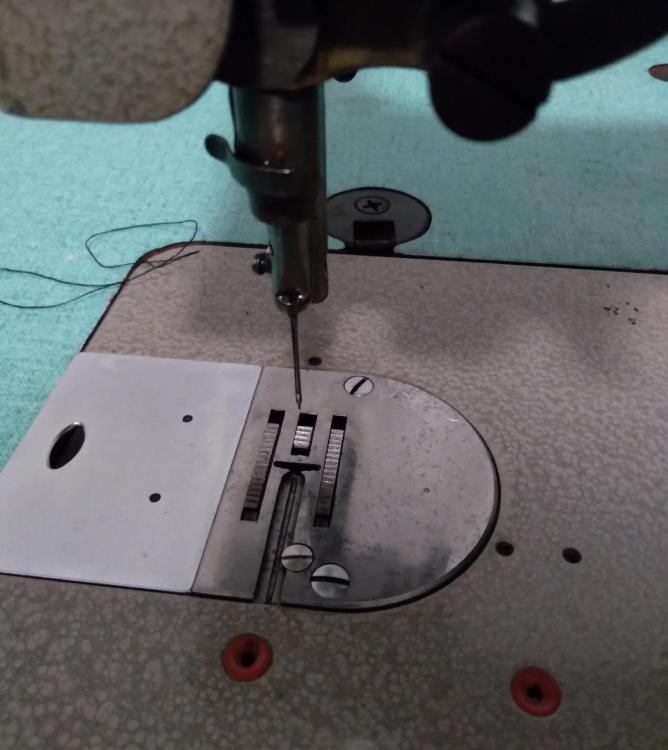

On your machine, is the binder synchronized? I’ve made two plates the black one from some scrap metal and the shinny one from an old Singer 111. I don’t make it synchronized, I could by connecting to the feed dog. First I’ll try it this way. Also, be made a hook cover out of 3pt die cutting rule. It is a couple of mm short but it covers all the sharp parts of the hook. The steel is good quality steel and it is held in place firmly by itself. It will comes off only if I have to fix the hook timing Here are some photos. -

Singer 108W20 - My New Binder Setup

George1520 replied to Constabulary's topic in Leather Sewing Machines

I think I will try to make one from a measuring cup. It looks like it belongs there. Or make and open end circle like the one on Pfaffs. I’ll make one out of die cutting with the bender. -

Singer 108W20 - My New Binder Setup

George1520 replied to Constabulary's topic in Leather Sewing Machines

I just picked up a machine like yours. Older I think. It works but it has a couple of missing parts. The end cap at the cylinder bed and the plate/binder attachment. They guy I got the machine from, used it sew wallets, I’m planing to use it as a binder and to sew pull tabs on shoes. Sooner or later I will get the either get the shoe or my finger caught in the hook. Do you know where to get one? Or if the one form another’s machine will fit. Like a Consew 277