George1520

Members-

Posts

58 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by George1520

-

That is tall. Do you know how much it weights? I guess the force is not that important because I can click it twice. Also, what is a good price for a press like this?

-

When this happens does the press clicks at random? While setting the die or moving the head to the die or just after pressing the button to click. I would like to own ten fingers. Looks like they still sell those presses on http://www.shoesmachines.com/5-ton-clicker-press.html and they say it is a 5 ton press. I'm looking at getting one of those clicker, to use in cutting shoe uppers. Will it have enough power to cut a full upper? Thanks George

-

Screwdriver and a hammer will work too.especially if you heat it up with a touch

-

Like new sewing machine Made for shoes and softer leather. Pfaff design sold by Nick-o-sew. Ball bearing, automatic oiling, 5mm stitch length. No reverse. 800 plus shipping

-

1000 plus shipping. I’ll build a wood box for shipping

-

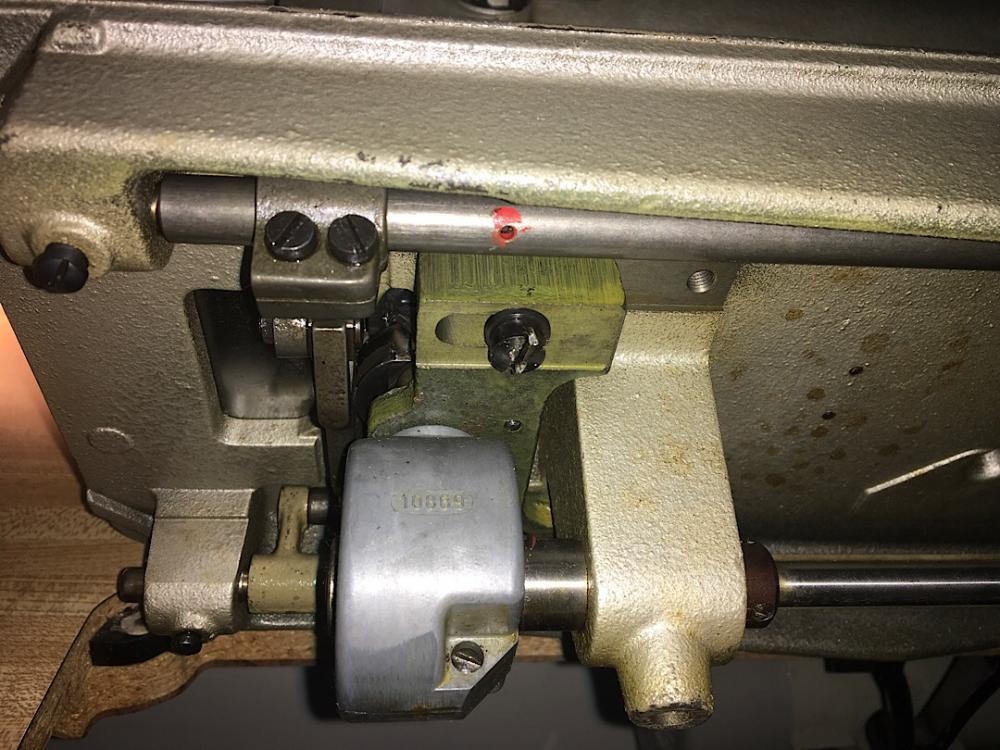

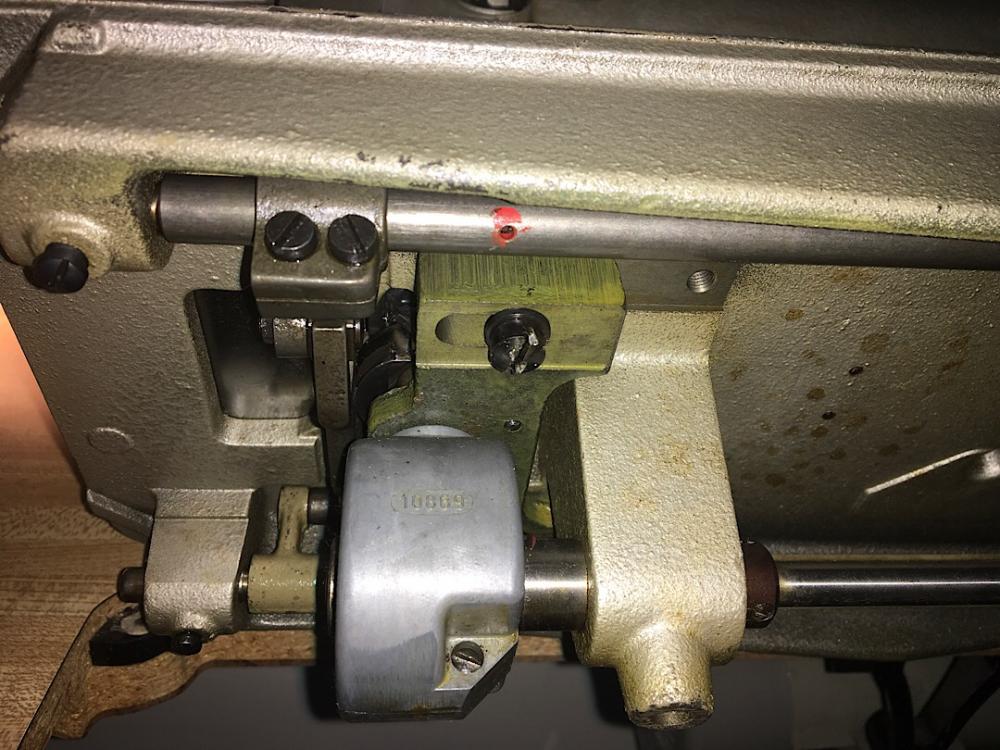

I have an extra Pfaff 145 in great condition that I’m trying to sell to finance a post roller feed machine. Complete and like new machine, no worn parts. The head of one of the big screw that adjusts the hook is a little scared. It works fine,it is just cosmetic. Please see the image. If you live in Colorado, I have a table for it.

-

I have an extra Pfaff 145 in great condition that I’m trying to sell to finance a post roller feed machine. Complete and like new machine, no worn parts. The head of one of the big screw that adjusts the hook is a little scared. It works fine,it is just cosmetic. Please see the image. If you live in Colorado, I have a table for it.

-

Im surprised no one mentioned Consew 146 or 199, that are used in the shoe industry for joining leather. Like in the heel area. The 146 will be better because it is a walking foot and it will keep the pieces together in place before starting to sew. there is also the the type that sailrite sells or Reliable Barracuda but it is small and one of the foot is really close to the material. In any case you might want a machine that will make a zigzag wider than 4mm

-

Can anyone help me identify this thread? It is nylon but not bounded. I just need a name for it to find some. Thanks

-

Limitations of Last Modifications

George1520 replied to AdamGadut's topic in Shoes, Boots, Sandals and Moccassins

My father said that my grand grandfather used hard red seal wax to modify lasts. That was before plastic lasts. If you are in a hurry plastic lasts are a lot easier to work with. You just melt some milk gallons , spread it with a butter knife and grind it to shape. You can also look for George Keloff’s Last Designing and Making Manual book and video it has step by step instructions on making lasts But why not use leather like everyone else? I’m sure you can find some on the leatherworker.net ;-) -

I was surprised to find plastic gears in my 230. The Pfaff 130, 230 or 360 type of sewing machines have two plastic gears one driving the hook and one at the zizgzag fork. I don’t think it matters that much because it doesn’t require much to turn the hook and make the needle from left to right. But those plastic gears get old and crack. I do like the build in knee lift option and I think that makes a big difference sewing small pieced. The problem I found with domestic machines is that, they don’t feed as well and you have limited choices of needles. If you don’t sew thick leather a sewing machine like Singer 20U with a servo motor would work

-

I'm looking for a supplier for micro suede and real suede. I would like to use both in combination in making shoes. Find thin micro fiber but not is not a problem, but I need micro suede around 1.4 or 2 mm thick and real suede the is 5 oz. Thanks

-

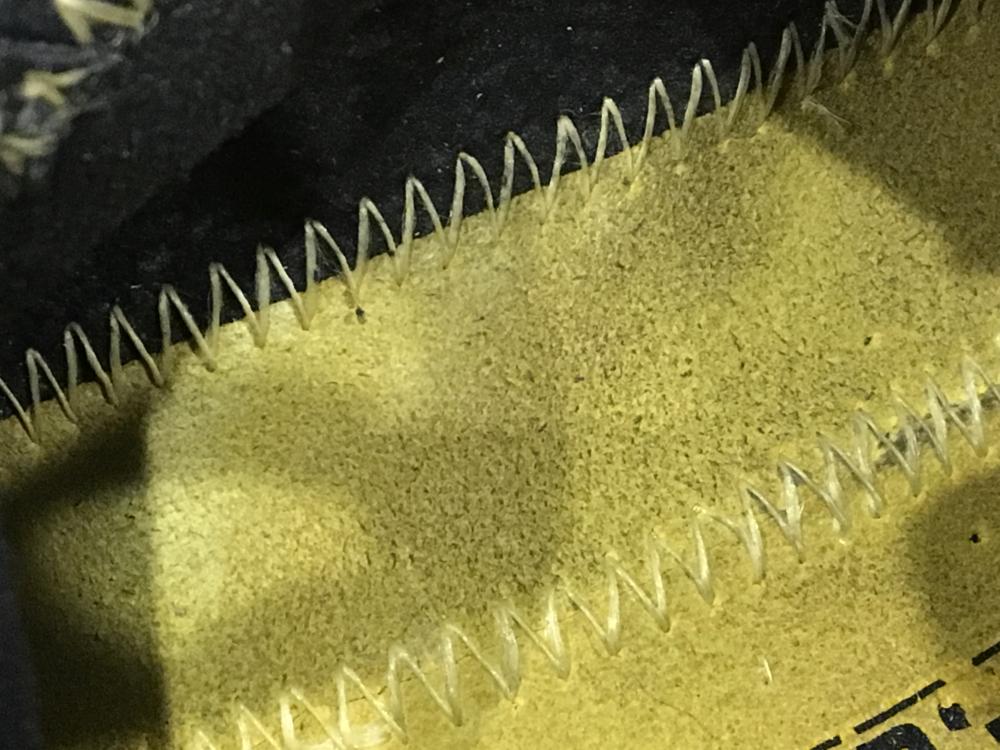

Hey Gregg That is what I'm looking for. I didn't know that Stager made the first version of the machine. What is the equivalent Seiko model? Do you have a pdf of the manual? I was playing with the cam in the image but I was moving it more then 1.6mm. Since last week the machine has been taken apart cleaned and put back together. Now I have to adjust everything. Thanks

-

It is good enough for government work it is good enough for me. Chapter 4 has good info on Consew Model 225, the Juki LU-562, the Singer Model 111 W 155 & 31-15 sewing machines http://militarynewbie.com/wp-content/uploads/2013/11/NAVEDTRA-14217-Aircrew-Survival-Equipmentman-1-C.pdf

-

I'm looking for a repair manual for the Consew 146 not the parts or instruction manuals. I have those. The machine I have feeds backwards and the thread gets fought in the bobbin finger holder. It needs some more adjustments but those two are the major problems right now. thanks

-

I NEED ADVICE ON THIS ADLER SEWING MACHINE

George1520 replied to jollins's topic in Leather Sewing Machines

Just curious. Does it have the walking foot drive or it is a only a roller foot? -

I was watching a video on youtube and a french shoemaker lighted the contact cement on fire after he apply it to the shoe. He said that will speed up the drying time. I did a google search and supposedly cyclist call it hot patching. Any of you set the cement on fire? Does it waken the bonding strength? For your enjoyment https://www.youtube.com/watch?v=Zwq59bBJSbs

-

I like cheese. Melted cheese to be precise. Bronze is easy to weld with a tig. I used to work in a foundry for a while and making a big sculpture is done in pieces and welded together. Also, imperfections in casts are filled by welding and than chased the welds. You can't even tell the difference. Unless, you switch the arms around on a sculpture. One guy at the foundry welded the the left arm were the right should be on life size sculpture. It tool the sculptor while to realize :-) if you really want to fix it do this. Time for fondue

-

The best way to weld cast iron is to heat it red hot first and then braze it with bronze roads. The heating part is important and it it will destroy the paint around the weld. Unless you have other cracks, leave it the way it is. There is still plenty of tread and and material for to nut to tighten. Also, look for bend shafts too.

-

Ok that was in much worst shape than my machine is right now. That is what I was thinking of doing, but only to the part that is perpendicular to the bed. I don't think I have to weld the whole crack, because it stoped at a bolt hole in the middle of the bed. Did the weld crack again? Cast iron is not that easy to weld, and welding it with nickel roads is not the strongest way to do it. UPS doesn't want to do much about the damages. They send me to the UPS air cargo office in China, and the office in China doesn't want to do anything until the I get a letter from the forwarding company that the seller used. It is the forwarding company that has to file the claim until I will get the letter. So if you do ship something do it on your account, otherwise you can't file a claim. The other thing You want to do is open the package and inspect the contents before you leaving UPS. If you don't the will say that it could've been damaged after leaving the station. Also, UPS made me sign a paper that I received the package undamaged before they actually give me the package. And they charged me 30 bucks to actually bring me the package to the door of their station. The people I met there were nice.

-

I doubt 1/2 pig iron casing would help they managed to crack that already. The shipping was airfreight from China for a zig zag post sewing machine and a skiving machine. Both packaged were damaged but only one is in bad shape. I could not find this type of machine in the US. I just heard from the people that sold me the machine. After I send a video they told me the machine is junk. Anyone needs any parts for a Consew 199 or 146 type sewing machine?

-

Who is there to blame? UPS charged me 500 to deliver the head, that is a lot of money I paid them to destroy something. I know how they operate. My father worked worked for shipping companies for 20 years. He used to pick fights with coworkers because he was disgusted on how they handled packages. It was packed in the original packaging form the factory and tied to a pallet. I'm sure that manufacturers would not send thousands of machines just to to be destroyed before reaching their customers. At my last jod we purchased and had to ship back an 48 inch printer because they did the same thing. Crushed one end of the box. The paper roll carriage was bend about 5 inched. It probably it probably costed them 5 or 10k

-

I've been in contact with the seller. They handled the shipping and they didn't get insurance. I called UPS the next day after I got the machine and they want me to open a claim. That was Friday when I only knew about the crack, I will call Monday again after I talk to the seller. My father used to work for DHL and he said that is nothing out of ordinary. They throw around and drop packages all the time.

-

I finally got my sewing machine and UPS managed to mess it up real good. The machine is similar to a Consew 146 but it has a post bed instead of a flat bed. They hit the flywheel hard enough couse it to bend. I didn't notice that, because I got distracted by crack in the middle of the bed and the 90 degrees bend in the needle. Luckily the crack stoped spreading where there is a bolt hole. I could live with the crack but I could not recenter the needle, it still hits the back of the feed place away from the operator. Or that the machine turns really hard. The clutch motor has a hard time starting to turn the machine and when it does it give full speed for a couple of seconds and then the clutch starts to sleep. When I turn the machine by hand (no belt attached) it is difficult to turns. It turns for couple of rotations and then it gets binds and then starts turning again. It might be because the main shaft is bend. So my question is. Is it wort to get it fix? And anyone has any experience with gettting reimbursed for a broken machine? Let me know if you are interested to see video. I'm going to make movie to show UPS. Thanks