Double U Leather

Members-

Posts

655 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Double U Leather

-

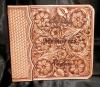

Custom Cattle Show Halter

Double U Leather replied to Double U Leather's topic in Saddle and Tack Accessory Items

Thanks for the nice words gang. The customer picked it up today. It was actually a belated birthday gift for his son. He brought the son along with, and the lad was just beaming! I love to see the look of a satisfied customer, especially when it's a kid. Eugene....I made it with 8-9 oz. HO and lined with 2-3 oz. Royal Oak. -

Finally able to get something knocked out in the shop. Been on the road doin' my real job and now am home for a few days. This is the first time I've ever made one of these, but it turned out okay. Pretty basic...brand on the nose with basket stamp, and a name on the cheek pieces. Anyway, have a look and let me know what you think. Prayers to my neighbors to the north in Ft. Collins. The High Park fire is a doozy. Friends lost their house and a probably some of their horses. Be blessed gang.

-

I'm an electrical tape guy myself. I have a couple of other tape issues I have to deal with too. On my ring finger, left hand, I've got a stinkin' little wart that the over the counter stuff won't touch. I've tried DMSO (not to be used for human consumption...equine only) and it isn't even working. So...when I've got a lot of beveling to do, I crack out the duct tape and away I go. And, duct tape actually kills warts in time....or so I've heard. Sometimes it gets kinda rolled up and I get the sticky on my tools, but it's not too much of pain to get rid of. The other "age related" I'm finding out is I've got a touch of arthritis in the first joint of my pointer finger on my right hand...you know, the finger that fits into the saddle on your swivel knife. Doesn't hurt too bad when I'm working, but at the end of the day, dadgum gets tender. Maybe it's the result of riding bulls way back in past life. I don't know, but I'm not any too thrilled about it. As was said earlier, savor your youth....one day you just kinda wake up and go..."Dang...I'm old". The thought of my birthday a year from now is making me a bit sick. Fixin' to not be in my 40's anymore. "Dang...I'm old". LOL.

-

Thanks for the kind words. The real hard part was getting the edge to be straight when all of the middle is cut out. It wanted to get wavy. The gluing process was also kinda tough. I actually had to take a scalpel and shave the parts of the hair on down to the hide so I had something to glue to. And that gets real tricky so as not to shave a spot bald that won't be covered. Used typical Barge for the actual gluing. I don't know off hand what my machine is. I want to say a Singer 411, but without looking at it I'm not positive. I use 138 nylon thread, and probably 9 stitches an inch. Again, without looking at the setting, I'm not positive. I sew just about everything at that length. I'm really not much of a person who tinkers with my machine once it's sewing good. I really do need to work on that end of this game i.e. construction, stitch lengths, etc. I tool okay, but I sometimes really struggle with the other stuff. Anyway, gator should be easier since there's no hair to deal with. I might try another inlay project just for giggles to see if I can dial it in better. Thanks again for the compliments, and stay blessed.

-

Here's another order out the door. It turned out okay, but nothing stellar in my estimation. The inlay was a booger to do, and it didn't come out as straight as I'd have liked it to. But, I'd never done one like this before, so there is that stinkin' learning curve to deal with. Glad it's done. Now I've got one more thing to do in the shop before I hit the road for a month doing my "real" job. Anyway, take a look and let me know what you think. Any tips on how to do these would also be greatly appreciated. Thanks for looking and stay blessed.

-

Satin Shene As Resist?

Double U Leather replied to DaltonMasterson's topic in Floral and Sheridan Carving

I'm a Neat lac fan myself, but I have to admit, I've started using RTC from Bee Natural and so far have had real good results. If I've got something that has a portion dyed, I'm leaning toward RTC. Speaking of dyes, I switched to Angelus black and that seems to be light years better than Fiebings for me. No smear when applying resist on top of it. But, then again I'm using the RTC in a spray bottle for things like that. Anyway just my $.07 (figuring for inflation....LOL). -

Jon, On this project I used the RTC rather than Clear Lac, but yes I did put it on over the top of the Cova. I let the Cova dry for several hours....maybe even overnight. And, I used a spray bottle to apply it. I've ruined more than one project rubbing Clear Lac on over the top of dye. I didn't want to even risk it whether it be RTC or Clear Lac. I think for me, the hardest part of getting my game up to the next level is the finish work. But, I'm gonna keep pluggin' away and experimenting with stuff 'til I find the magic touch. Keep being blessed.

-

Floral Bible Cover For Preacher

Double U Leather replied to BearMan's topic in Books, Journals and Photo Albums

Very nice. I'd also like to see more pics...especially of the insides. I'm not sure what you meant about how the Bible sits in there. As for the Angelus dyes, I switched to Angelus black a couple weeks ago, and I'm sold. I don't think I'll be going down the Fiebing's road anymore. Anyway, excellent work. -

I'll second the Springfield Leather reference. I've bought alot of Herman Oak sides from them, and they are super people to work with. Fair on prices, and a wealth of knowledge. Sure enough stand up folks.

-

Jon.....thanks again for your compliments. I don't know about killer, but I feel like I'm kinda getting there. But, I'm sure not even in the same ballpark as some other folks on here i.e. Hidepounder, John Ivy, Clint Haverty, etc., etc. Nonetheless, I still keep striving to improve. As for the finish, I use Tan Kote and rub it on with sheepskin. My whole finish process is basic Sheridan. Oil, ClearLac (now using RTC from Bee Natural and really liking it), antique, Tan Kote. Too bad you don't live closer, I'd be happy to sit down with you and show you stuff I've learned about Sheridan style along the way. Anyway, thanks again for your kind words, and I hope God blesses you.

-

Thanks for the nice words guys...I appreciate it. Jon...I used Cova color dyes. I don't know if they're acrylic or not....LOL. I tell ya, I'm not real sharp on that kinda stuff. Ken....thanks for the bit of history. When I googled the logo, it did say it was the US Army Air Corp. The customer sent a pic of the logo type she was after. BTW.....the customer picked them up this afternoon, and was pretty excited with both of them. In fact, gave me a $10 tip!!

-

Here's the next item done. This seat goes with the other one I posted a few days ago with the eagle on it. The customer bought one for her brother, and this one for her dad who was in the Air Force in WWII. I wasn't sure how it would look dyed and all, but I was pleasantly suprised with the finished product. I hope the customer likes it as well. As always, thanks for looking, and let me know what you think. Blessings to all.

-

Really nice work. I've got an inlay job coming up using hair on hide instead of stingray. Hopefully, it turns out as well as yours. Speaking of 'ray, I've heard it's a bear to sew. Any tips on working with it? Great job.

-

Here's another order out the door. These were a bit out of the norm for what I've been churning out, but it's what the customer ordered. I did learn something on this project. Steel guys call their maker's marks "touchmarks". That's the C hammer F deal on them. The customer is a knife maker, and the big one with the bone handle was one bad cat of a knife. 11" blade, and made out of a horseshoer's rasp. Very cool. I should have traded him the sheath's for a knife...LOL. But, as always, I opted for the $$$. Take a look and let me know what ya'll think. Stay blessed.

-

Iphone Case

Double U Leather replied to Double U Leather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Robyn, Apparently, I didn't make a pattern for this project, but simply measured and used a square and drew it on the leather. I'll check my notes and give you the measurements at least. Sorry. I do things kinda bass ackwards alot....LOL. -

DC....I don't know if Angelus or the RTC that cured the problem, but I'm not going to mess with it. I finally found a combination that works. If it ain't broke, I ain't gonna fix it. Both the RTC and Angelus were suggestions from Barry King. I figure he's much more of a guru than I am, so I'll just listen...LOL.

-

Iphone Case

Double U Leather replied to Double U Leather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Robyn, I'd be happy to send it to you. Let me see if I can find it. -

Thanks Jimbob. I appreciate the compliment. Terry....I've had Fiebings oil base dye smear, as well as Fiebings mineral dye smear. I've dyed things let them literally dry for a couple of DAYS and when I wipe on the the Clear Lac, the smearing begins. And, I've buffed the dry dye, oiled first then dyed, dyed first then oiled.....you name it. But with the Angelus dye and RTC, not a hint of smudge or smear.

-

Couple Of Bible Covers

Double U Leather replied to Chief31794's topic in Books, Journals and Photo Albums

Those look good Chief. The owners will be proud to carry the Word of God in them. You're right about different Bible sizes too. Anytime I get an order for one, I insist on the customer sending me the Bible the cover is supposed to fit so that I can make exact measurements. Good work. -

Terry....I've never tried the Bee Natural oil. As happy as I am with the RTC, I sure might think about it. Barry is the one who recommended the RTC to me. I called him in a twist one day after the Fiebings smeared on me. He suggested the Angelus dye and the Bee Natural RTC. And along the way, it seems I tried every combination in the world...neatsfoot, then dye...dye first, then neatsfoot...same methods with EVO...let it dry for days...let it dry for minutes....same results. I never had any trouble back in the day when they made Neat Lac in an aerosol. When I had to start using Clear Lac and wiping it on with sheepskin, then the train wreck began. As for the antique, I'm using Eco-Flow gel. It seems to work okay for me. Goes on smoother and less blotchy for me. Anyway, thanks for the nice words, and the hint about the Bee Natural oil. Dallas...I cut my own. The first thing I do when I get a side is square off an edge (neck end to other end), and then cut about 3 or 4 strips the length of the hide 1 1/2" wide. It seems I sell quite a few belts, and I always like to have plenty of belt making material on hand. My base price for the floral belts starts at $225. This one, being dyed, cost the fella a tad more...LOL.

-

I don't really know what RTC stands for. It's a product by Bee Natural and came highly recommended by various folks. I was having a lot of trouble with the Fiebings dye and Clear Lac smearing. There wasn't an ounce of smear using Angelus dye and RTC. I promise you, I was as nervous as a barefooted boy in a red ant pile when I started putting the RTC on. I could just see the "smear gremlins" ruing the whole thing. Thank God, literally, it worked out.

-

Here's another order ready to go. I really, really like how this turned out. It's background is dyed black, with wide dyed edges. This is the second project with the RTC resist. I'm liking the RTC. And, this is the first time with Angelus dye. It's way lots better than the old Fiebings. No smear, no streak. Anyway, take a look and let me know what ya'll think. Stay blessed gang.