-

Posts

42 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Brownie1

-

So after reading through the thread I am aware of all the basics, thread size, needle size etc. However taking the suggestions again I decided to retrace my steps with good thread, brand new needle proper for thread size and material and then retraced how I was threading the machine. Turns out due to my declining vision I missed the hook between the tensioning springs and with the new needle it worked out and started to sew properly. So just wanted to say thank you for making me retrace my steps; it fixed the problem! yeah!!!! On a side note, there are no marks on the needle bar to assist with setting the timing. So I was wondering if anyone had any manual on how to set the timing and specs for a rather modern day Singer. I have watched some instructional video on how to set some of the machines up but would like something more detailed or specific; not sure if what I'm asking for actually exist?

- 4 replies

-

- set up timing

- model 2732

-

(and 2 more)

Tagged with:

-

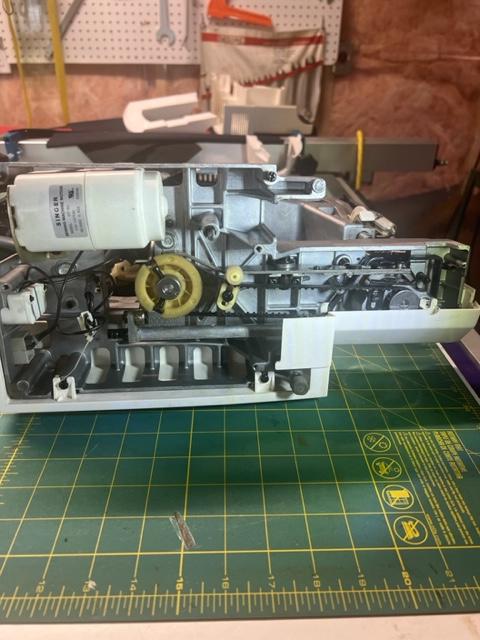

Could some one give me some advice on how to set up the timing on a Singer Model 2732. It's not a heavy duty machine it is supposed to sew zigzag and decorative stitching but everything seems out of wack. It breaks thread and sounds like things are binding internally and skips stitches; I'm sure it's the timing. Does anyone have instructions on how to set this machine? Any information would be greatly appreciated. Thanks Kevin

- 4 replies

-

- set up timing

- model 2732

-

(and 2 more)

Tagged with:

-

Hi guys, I'm looking for some advice as to what machine to go with if I were to purchase one of the 2 machines. Either the Consew 227R or a Mach 3. They are both comparable in price. What are your thoughts? I'm presently making small leather goods such as passport holders, some leather and canvas bags and change holders out of veg tan leather. Thanks Kevin

-

Tote for wife

Brownie1 replied to wkleather's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Someone's wife is going to be happy .... great job! -

I recently ordered a part for my machine, a guys said he had a race for a singer class 7 that would fit my 7-55 so I went ahead and ordered the part from him. I don't know what he sent me but it definitely does not fit my class 7. does anyone know what this part would be for? The guys I am dealing with was closing for the day so he said he would call his supplier in the am, he seemed good and knew what he was talking about. The old race is the smaller one, obviously.

-

Another question, the presser foot on this old 7-55 makes it so that it will not climb over welts. The front part of the presser foot (toe) once it hits the seam or welt it lifts the rear portion that makes contact with the feed dogs and thus the material does not feed. Is this normal for these old machines? I'm not sure what to do to combat this issue, any ideas would be great.

-

Thanks for all the good information guys I appreciate it. For some reason, and I don't know why, but it looks like someone had modified the race, it doesn't seem to have any effect on the machine other than the shuttle frame moves more when it gets to the top where the race was modified. Long term effect it may compromise the shuttle frame???? I was thinking of ordering a new race but I'm being cautious.

-

Constabulary you are awesome!!! In the third photo with the large screw head on the slide with locking bolt on other side, I moved it as far down the slide as it would go and it did what it was supposed to. I can put 1/2 inch or more of material under the foot and no problems. Thank you Now do you have any good sources for presser feet for this machine?

-

Constabulary, here are some side shots of mine. It looks like one of the arms have been pinned so I'm not sure if that's normal or not. Is it possible that it was pinned at the factory that it was being used at back in the day to prevent slipping or prevent someone from messing with it?

-

Hey guys, I recently purchased a Singer 7-55 and have been cleaning it up, of course after taking things apart and cleaning and then putting them back together when the presser foot walks over the fabric the rear foot the one without the needle does not seem to lift as high as I want it to. So as it makes the step and then picks up the rear foot to spring forward, it doesn't really lift that high. I was alway under the impression that it would lift higher. Is there a way to get follow up foot to lift higher off the material after it completes the stitch?

-

-

Yes I agree I could watch that video all day as well. Makes me want to go buy a class 7 LOL

-

Thanks JJN, the big question is do you buy the machine and set it up and keep it for big jobs. Really not sure what you would use the machine for. I have done some reading that it was possible used for canvas tarps and ropes. Not sure why or how they would sew ropes together.

-

Restoring OEM Stitch Length on Singer 29K70

Brownie1 replied to Snakeoil's topic in Leather Sewing Machines

Make sure you take before and after pics of the model 66, love to see how it cleans up .... being able to produce your own parts is a hugh bonus Snakeoil. -

Definitely overkill for what I want to do for now, and yes don't really have the space. Factoring in just those 2 things I just mentioned, the $1600.00 price tag is too high. Now if the person wanted to sell it too me cheap maybe my wife wouldn't mind it in the bedroom . Thanks for the input guys. Check out this other machine that's up for sale as well Singer 47K5 for $750.00.

-

Thanks shoe patcher, what does everyone think of the price?

-

Pushing the old Durkopp 239-125

Brownie1 replied to toxo's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Wow that is sweet! Nice job, your daughter should be very happy. I just learning the craft but I'm hoping to work up to that quality. -

Restoring OEM Stitch Length on Singer 29K70

Brownie1 replied to Snakeoil's topic in Leather Sewing Machines

Good tip snakeoil. I don't know how many times I've dropped a part or even the hook when changing out my bobbin. I cringe as I watch it hit the floor and pray it didn't damage. Wizcraft gave me some good information to get this one 29K71 up and running and Bob from Toledo Industrial Sewing Machines also helped me out with parts . -

(Singer 7-33R) Came across this machine for sale what do you think of the price tag $1600? Even though they say it functions well how hard is it to get parts?

-

I have to say that it has been rather rewarding both working with leather but also cleaning up vintage sewing machines bring them back from being just a decorative item to a working functional machine. Machines that work by treadle are my favorite and I'm not quite sure why. I guess it's a time that some people have long forgotten; when we didn't have gas or hydro.

-

Restoring OEM Stitch Length on Singer 29K70

Brownie1 replied to Snakeoil's topic in Leather Sewing Machines

Hey guys, great information here, I've also had some of the same struggles with my 29k71. I replaced the free motion cam roller which sits directly on the back of the head and my machine improved to where my stitch length was acceptable for me. I was also going to go a step further and replace the roller on the rear cam but found the machine performance acceptable for my needs; plus I wasn't quite sure if I should screw with pulling the rear cam on the machine. Great information on this thread! -

Dear Kevin, Thank you for your inquiry. As far as we are aware, needles for Junker & Ruh machine are not available anymore. We had some requests last year and we then made quite some inquiries, also at the 2019 International Shoemaker Trade Exhibition in Wiesbaden/Germany, but no helpfull info. If we can be of service to you in any other way, please let us know. Best regards,Allen Jongepier Dear Kevin, Allen Jongepier https://www.power-shoe.com/en : ( No needles here, and the person on eBay does not respond. Any other ideas please let me know guys.

-

Hi Silverback, I'm looking or any needles for Junker and Ruh SD 28 5,6,or7. I found this thread and was hoping you might have some extra kicking around that I could buy? Kevin