-

Posts

115 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by AlamoJoe2002

-

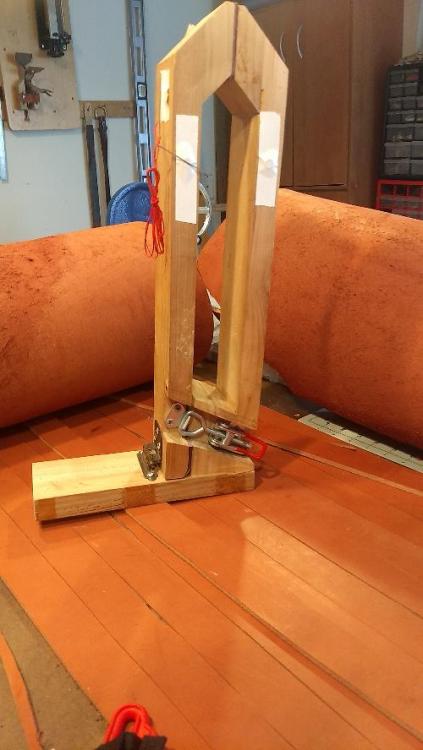

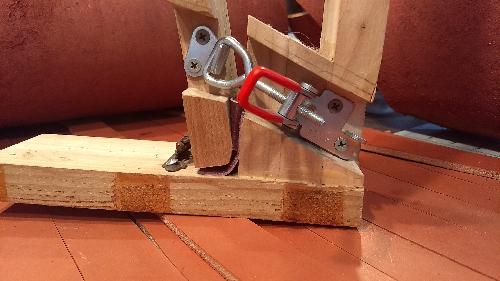

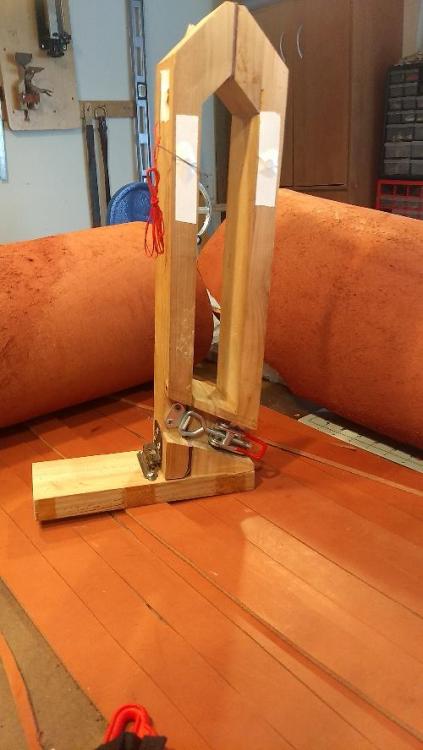

Hi all! I also made a stitching pony with a used kitchen cabinet hinge and cam-lock hardware. My jaws are lined with thin leather. I am experimenting where to put the magnets for my needles...thus the taped down magnets under the white duct tape. It is designed to clamp onto a bench or sit in a chair under one of my legs. I have no clue on attaching pictures...but I resized them. In the back of one of the pic's you will see a inverted driftwood tree root bird house I'm making..."never slow down, never go old." Joe

-

Round Knife workbench stand STL file

AlamoJoe2002 replied to chrisash's topic in 3D Printers and Lasers

Chrisash, Nice work. I also liked your 2 round knife concept you displayed in an earlier post. I don't have a printer but could find someone...I know the University of Colorado has one in their student library. So...maybe I can find one at a more local university....or I'll send the file to my friend who is on staff at the University of Colorado and ask him to make one. Can you send the files/ single and double versions in a PM to my message box here in leatherworker? I'll provide my private email address to send the file. I have a few bits of 13 oz leather. I'm thinking of taking your design and making a stand up box using what I have. I think that may be a good start for trading ideas on storing the round knife on a workbench in a handy location with the blade not drawing blood every-time I reach in the last general location for it. My other consideration is with all the time I'm investing in sharpening my own tools I don't want to mess with an edge that took time which had me put on another band-aid to stop the bleeding. Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

How about I configure and mount a ceramic tile onto the orbital rubber pad and eliminate the soft moving vibrations? Will a hard baked sandpaper do a nice job? I have an idea where I will use spray adhesive to mount the sandpaper on a granit or marble floor tile. Then make a linkage-dinky-mount on to the orbital sanpaper machine... Or take all the rubber off the sander and replace it with solid metal or ceramic to attach the sandpaper to the sander.... My friend always is telling me I am over-thinking and incorporating unnecessary steps in a process to achieve results desired.... Make me go Hummm...and my wife kicked me out of my own shop a few hours ago. Looks like tomorrow night is a date night. JOE -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

Here are pictures of the Osborne Blade after I scrubbed the black iron oxide in water, rubbed down with acetone to prevent flash rusting, then rubbed the blade with WD40. The WD40 seemed to hydrate the wooden handle. I just let this air dry after pulling it and treating it to prevent flash rusting. I saw a round blade kit that had a few magnets glued flush in wood on youtuber where an individual was developing a sharpening system for round knives. I did something similar but used a piece of granit counter top trash picked on the side of the road. I might not be making any leather goods but I am sure enjoying making a few things and keeping my mind and hands busy. I started at 40 grit sand paper with a block of wood by hand. I have since moved to 60 grit. I think I will experiment with an orbital sander next. The blade does have character and will remain that way. I received a quick reply from B about their product. Here is a cut and paste from the email. I will say the company is customer service driven. "Please see attached product flyer for Belzona 1111. This would be your best bet from a Belzona perspective. 1kg unit is $281." No epoxy for this renovation! And...I don't see any benifit of filling in the pitting and eliminating the "character" of the blade. The next update will be when I get time to sharpen and polish the blade. Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

Thanks for all the great feedback. I saw a video on rust converter (phosphoric acid). I will hunt this down. I used this in the past as part of the process of recoating petroleum storage tanks that were rusting to prep for epoxy painting. Great stuff...I bought the coating from a local paint supplier (Sher-Erwin Whatever). After 48 hours I notices a very small on going reaction. I changed the solution, scrubbed the rebar with a wire brush to expose good steel, scrubbed the knife with a brass brush to clean off the black coating from the electrolysis. Below is the dirty solution. Here are pics of both sides of the round knife. My focal point is looking for the star under the Osborne Makers Mark. It is there and faint. I reloaded using distilled water from the dehumidifier and less quantity of washing soda. I restarted the reaction and it was 20 times more reactive than the 1st attempt. Very aggressive reaction. Below you can see the suspended knife and the reaction of the closest rebar to the knife. I went an checked the reaction and it was very aggressive. The solution had warmed...the 1st attempt never generated any reactive heat. I must have better connective areas of the blade and rebar (cathode and anode) since I scrubbed them. I attempted to load a 21 second video. I'm using a chromebook and can't find an good easy extension or app that will quickly resize the video to insert. Ideas on video software requested. I want to show this almost violent reaction that is ongoing and heating the solution. It's warm and bubbling. Enjoy. Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

That is a good observation Vintx. Originally I suspended everything above the blade, including ferrule above the solution. Then I moved the ferrule about 1/4" into the solution to see what the iron electrolysis will do to the copper ferrule. The should have no reaction to the electrical current. We shall see. Once the blade is removed from the solution I intend to place it in a oven at around 150 degrees F to dry out the handle slowly. The handle was tight prior to all this soaking. Once dry, hopefully it will return to the steady position it was in before the wood got wet. I never took apart a knife before...well once or twice with a large hammer...I thought I'd go with a little bit less effort on this handle. JOE -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

The blade has been in electrolysis for 40 hours and is still exhibiting reactivity on all the surfaces. I lowered it by mistake which put more of the tang into the solution and the reaction took off. The reaction resembles very little formation of smaller than a needle point to a pin head bubbles and appears to be an opaque white stream of material floating away from the blade. Here is the picture of the blade at the 40 hour mark. I will continue the process. Now I'm really interested on what will be left of the knife when I remove all visible rust and rust down in the pitting. JOE -

I would like to find a vintage round knife to shape sharpen and make my own. Currently, I'm working on a very pitted subject and I may be wasting my time on trying to shape, sharpen and put to work. This is my 1st round knife. Please send a PM (private message) if you have a reasonably price candidate. Joe

-

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

Thanks Bruce. You have got me thinking...may be I need a new specimen to spend my time on. I truly am looking forward to learn how to properly sharpen and use a round knife. The blade is still in the electrolysis bath. The pitting is still bubbling the rust away. It has been 24 hours and I don't see much of an improvement to the blade material. I will keep up the process and see how long it takes in solution for the reaction to stop. So in the mean time I am now on the look out for a round knife to clean up, sharpen , and make it mine. Right now I paid $26 US for the knife. I will begin the hunt for a new specimen. I feel honored to have Bruce weigh in on this project. If anyone has a vintage round knife they would like to pass along at a reasonable price please send a PM. I say vintage because the train of thought is the newer manufactured knives on the market are produced with lesser quality steel. JOE Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

Dikman: I have a belt sander...I'm looking for design ideas to change the symmetrical profile to asymmetrical...almost a two in one round knife. I was thinking I need a sharpening board to mount the blade on for sanding. I'm thinking about using a handheld sander in straight line sanding (lateral as opposed to round) movement. If I can use the 10 inch portable sander I can really work on a gradual reduction of material to the cutting edge. I have a feeling I will be starting out with 80 grit paper or more aggressive sandpaper and hours of relaxing mind numbing meditation while I hand sand this blade down. My goal is a sharp shinny blade and something like world peace... Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

The blade has been in solution under 3 amp DC Power for 12 hours. I checked it this morning. I pulled it out and wiped it off. I was expecting a black residue to cover the white cotton cloth. Not much...so back into the solution and power it up. I know the process is working as I observe a reaction on the full surface of the blade and around the ground down areas of the rebar. I'm taking this low on power and long on time. Another 12 hours and I will check it again. If it continues to have a very slow reaction as I have observed I will keep the blade on electrolysis. I don't think I can hurt the blade. However, I am concerned about the water content of the wood under the ferrule. I am thinking about the re-profiling the side of the blade where it chipped. So the question is how would you improve a standard round blade if it chipped a point? Joe -

I purchashed an original Osborne blade. It is too thick. Then I purchashed the same blade tuned up by Bruce Johnson. A world of difference. Rounded off tip for safety, thinned down and beveled correctly which produces a nice cut. However, I guess I should have known better than teaching myself how to use a draw blade on a side of 12-14 ounce skirting. Lessons Learned. Go big or go home...and always keep on learning. Fixing my mistakes is quite an educational experience. Joe

-

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

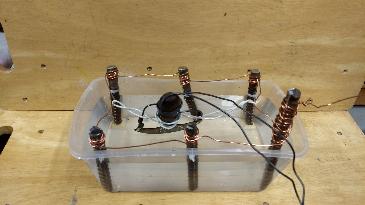

I made a quick electrolysis tank using an old laptop power source that converts 120 volt AC to 12 Volt DC @ 3 amps. I used a multi-meter to determine the negative and positive wires. I used a clear tub and zip-tied a few rebar cutoffs that I hit with a grinder to provide a clean conductive surface. The blade is hung using coated wire to where just the blade is submerged. I hooked up two alligator clips to the immersed blade which is the negative anode and the rebar is tied together in series as the positive cathode. The idea is to surround the blade with the cathodes as the current travels only line of sight. The solution is distilled water from my dehumidifier and Arm and Hammer Washing Soda (Sodium Carbonate) to increase conductivity. I don't know if tap water and a higher amp power source would work just as well. I am going to leave the blade in solution at the low current overnight. One of the good things about electrolysis is that new metal will not react...so only the oxidized metal / rust will be affected. The pitting will remain...but will be free of rust. I'm interested in seeing how the Osborne Makers Mark turns out. The key will be if the star is more visible under the stamp. Will it be more legible or will it fade away with the rust? This is the first time I have used electrolysis. I don't know much about metal...but if this lowers my sanding time on the blade I will be happy. I uploaded a few about 11 images. However, I may have screwed them up getting them into this forum. I resized at 364 pixels...I think at that size they have no detail. What do you resize your pictures for uploading to this forum? Tomorrow I will pull the blade out of solution, dry it off, and maybe put it in an oven around 180 degrees f to dry out the handle. Oh, part of the brass is in solution. Don't know how that will affect anything. Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

The knife just arrived via US Post. I did a quick touch up cleaning with xylene, a brass brush, a green scrub pad and a bit of wet 2000 grit sandpaper. The blade is solidly set into the handle. No movement. However, the blade is leaning toward the side with the Osborne mark. I will have to be very gentle with alingmnent. I will do this after sharpening. Now some choices...I might just try to use the electrolysis to clean out the makers mark....the star is very faint. I think I will forget about filling in the pits... The edge is as dull and pitted when I run my finger nail along it. Public Service Message: Don't go hunting with a dull spear...it's pointless (Your turn.). Here are the pics. I hope they load as I resized them to 364 pixels in width. -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

Gents, you have provided a ton of information. If the knife arrives today I will present a few pictures of the subject. I am not a knife maker and never forged anything in my life except my bond with my wife. Hah! And I'm finding I don't know squat! However, I have learned not to spend too much time on my hobby interests as that also gets me in trouble. I'll probably need a few counselling sessions by the time I'm done with this round knife...if you know what I mean... Joe -

Filling Pitted Round Knife with Epoxy for refurbishing

AlamoJoe2002 replied to AlamoJoe2002's topic in Leather Tools

I found this product which is sold as a metal epoxy designed for pitting. https://www.belzona.com/en/products/1000/1151.aspx I have no idea the cost... Joe -

I have an CS Osborne, Newark NJ, Round Knife due in which will be my 1st round knife. The metal blade is pitted. Hopefully I can work on the blade without removing the handle. I would like to remove the rust using electrolysis by suspending the blade into solution and adding current to remove the rust. Then instead of removing material to the lowest pitted level, I propose to fill in the pitting with a metal epoxy, then begin profiling the blade by hand using various grits of sandpaper. Do you have a few words of guidance for the electrolysis rust removal? How about products for filling in the pitted metal? How do I protect the manufacturing stamp when I begin to sand down and profile the blade? I also like the idea of reworking the #70 Blade into a more custom knife similar to the Terry Knipschield non-symmetrical Round Knife. Then again, I want my first knife sharp, shinny, and a pleasure to use as it will be mine! Joe

-

Hand Sanitizer as Reducer for Fiebings Pro Dye

AlamoJoe2002 replied to AlamoJoe2002's topic in How Do I Do That?

I experimented on an old leather belt using a Fiebings Pro light brown dye at 1 part dye to 4 parts hand sanitizer, 1:4 ratio. It reacted exactly as any alcohol reducer would. Didn't notice any benefit from the glycol. It may be a hindered as the effect on a old belt that wasn't stripped of the top sealer, as expected, had an non-uniform appearance. I used acetone and partly removed the existing top seal and am just trying now to get a consistent color on the well worn belt. Conclusion: Not cost effective to use as a reducer. However, will work is that is the only item on hand (humorous pun attempt) Respectfully,, JOE -

Any experience on using ethyl alcohol and glycerin (Purell) hand sanitizer to reduce Fiebings Pro Dye which is denatured alcohol based? I'm thinking reducing and thickening with glycerin will give me a lighter color and more control in applying. Thanks, JOE

-

Happy Merry Everything! I would like to buy a trifold wallet for a gift for my brother. He said black or brown...but I'm open to creativity. Maximum price is $50 and I will pay shipping. I can pay several ways. Venmo is easy and fast. Background: my family draws names for holiday gifts. This year I have my brother. I never made a wallet but wanted to find something from this forum. I sent him a card and told him I was still hunting. Maximum purchase price for our gift exchange is $50. I would like to see what people can offer here on the forum for this price. I’m in the Greater Philadelphia Area, Pennsylvania. If you have something you want to show me use the member mail system to contact me. Note: I have no idea where this post is allowed. I posted it in the Market place but it looks like its for selling...I will make corrections to post location as directed and do penance as required. Respectfully, JOE

-

Wanted: A $50 Trifold Wallet to Gift my Brother. Want to buy a trifold wallet for a gift. He said black or brown...but I'm open to creativity. Maximum price is $50 and I will pay shipping. I can pay several ways. Venmo is easy and fast. Background: my family draws names for holiday gifts. This year I have my brother. I never made a wallet but wanted to find something from this forum. I sent him a card and told him I was still hunting. Maximum purchase price for our gift exchange is $50. I would like to see what people can offer here on the forum for this price. I’m in the Greater Philadelphia Area, Pennsylvania. If you have something you want to show me use the member mail system to contact me. Note: I have no idea where this post is allowed. I posted it in the Market place but it looks like its for selling...I will make corrections to post location as directed. Respectfully, JOE

-

FF, I'm an hour drive from you...Philadelphia. I'm thinking of making my own press as a clicker press and heated stamp press. Did you take a look at the bottle jack designs as apposed to the arbor press designs? I also am looking at hydraulic actuators and screw type actuators which will use a 120 volt motor...trying to stay away from the hydraulic fluids which use air pressure to run the hydraulic pump which will supply tons of pressure....something that will move and reset quickly. I like the inexpensive magnets from harbor freight...however, I never compressed one to failure. I envision an press I can center an item on a plate which has an adapter bore to accommodate various stamps and set-ups. Let me know what you are thinking about. I have a friend who has a machine shop that will build what I need using recycled older presses...I need to get a custom clicker plate made for hole punches in double pronged belts or slings. Looking at Texas Custom Dies this week. Let me know how your doing neighbor. JOE

-

If your lathe has a mores taper #2 (MT2) you can find an inexpensive chuck from Harbor Freight (U.S.) for $12.00. Then cut your burnisher material, drill a hole for all thread rod up to 1/2 inch, secure burnisher onto all-thread with a few washers and nuts and you are in business. The H.F. has a MT2 and a chuck key. This is what I'm using. Not sure what type of design or material I'm going to end up with...but the lathe and correct cutting chisel will allow you to design your own. JOE.

-

1st Side of Skirting, How to Cut Belts w/Minimal Waste

AlamoJoe2002 replied to AlamoJoe2002's topic in How Do I Do That?

Thanks all. I'll look into the videos. Please keep the ideas coming. By the way can I get an opinion on the quality of the W&C standard side skirting? The color is inconsistent...is this normal? JOE -

I hope this inquiry finds you well. I am focused on making belts from this side of 12-14 ounce, W&C, Chestnut Skirting. It is their standard grading which was 26 sf x $9.42/sf + shipping. Under 2 weeks to arrive after placing order over the phone. I am new and have been working with chrome tan from salvaged couches. The dye isn't consistent across the entire side. I also see a lot of stretch marks. I don't know what I'm looking at as this is my 1st side and I'd like your thoughts on the material. what I'm After seeking advice for members of our forum I made a decision to start making belts. I have an Osborne draw gauge and clone 6" pull thru skiver. I have snaps and chicago screws. I need to order 1.5 inch and 1.25 inch buckles for mens belts. I don't know what women are generally looking for in bet sizes. Here is a pic of the hide taken on a ladder with out my belt on...I put the 38 inch sized belt on the side for scale. I think the dogs were weirded out for a minute... So I can begin making full length strap cuts. But that would leave short strap scraps. I would like to know what is a good side cut process to get nice normal sized belts and save larger portions of the hide for future projects. Respectfully, JOE