-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gtwister09

-

My latest saddle...number four for me.

gtwister09 replied to Elton Joorisity's topic in Saddle & Tack Maker Gallery

Bruce, I saw that one as well... I really like the carrier idea for the mart dees and rope strap versus the lumps. The rope strap lumps have always been something that stood out like a sore thumb aesthetically on Wades to me. I do realize that almost everyone does it that way but it still stood out as a sore thumb. Steve and Barra's comments about nylon, chaps and weak links have been drilled into me by my Dad and several of the cowhands that we rode with (over and over and over again...time after time....anyhow you get the idea. These were their pet peeves). I look forward to seeing more of them and seeing how they perform/hold up. Regards, Ben -

JW, Your experience with the strainer is one that is shared by a couple of saddlemakers that I have talked to. One of them used the trees back to Wilford and won't change out for nothing... Regards, Ben

-

I'm with Greg, It would not be practical. However I guess it's like anything else.....if there's a will there's a way. Regards, Ben

-

rht, They look nice. The finish looks nice also. Welcome aboard! Taking time out has happened to a lot of us. Regards, Ben

-

Ray, I don't know if you already know Francis Burdett-Mills at The Leather Connection but he would be a good contact over there. He is generally very helpful. His email is Francis Burdett-Mills. Regards, Ben

-

Warren, Gomph-Hackbarth Leather Tools 10754 N. Martineau Road Elfrida, AZ 85610 520-642-3891 Hackbarthtools@hotmail.com Regards, Ben

-

Tina, The first one on the chart under irons got messed up. It appears to have lost the decimal point. An ounce is equivalent to 3/4ths of an iron. Regards, Ben

-

Greg, I do remember that one. I do not know who got that stamping stick. In fact I think that he may also have that on his video set as well. It has been more than 12 years since I looked at the videos so I may be mistaken. I know that he had some rhino and elephant rawhide both at one time so it is likely that it was one of those. Both would be extremely durable. I don't remember which one he used. I might watch the first one with the majority of the tools and see if he comments on it. Regards, Ben

-

Marlon, Thanks. I had heard that as well..... He fit the part quite well! Regards, Ben

-

Not to pick on anyone but here's one of the many reasons that I believe in pictures being stored locally on the forum's server. Regards, Ben

-

Bree, Imelda Marcos now that's a blast from the past.... Bob isn't the only one that has that many...Have seen several pictures around with that many and more. Greg, The one that looked like Bob's only worse was the double ended. Tne one with lead was single ended and made of lignum vitae. It didn't make sense to me to add that much lead with that heavy wood. Glad you like yours. Regards, Ben

-

Art, Looks like it beats a soldering iron. Hmmm.. Regards, Ben

-

How do I sharpen the blade on splitting machine?

gtwister09 replied to ruthless's topic in Leather Tools

Bob, It does have a lot of GREAT information and it uses jigs.... It would be fairly easy to use his method for splitter blades especially the smaller ones. It would only take slight modifications to do the larger blades. Regards, Ben -

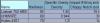

Greg, I had a couple but don't use them anymore. One was extremely poorly made and the other had so much lead in the end that it was too top heavy (the center of gravity was about 1.25 inches from that end).....so I never really took to using them. Bob, I had one of those but never really liked the feel and the action of them. I gave it away (Don't worry it was a 24 oz). However I have to add that it did seem a little better for stamping basketweaves and geometrics. So we adopted some of the ideas of the heft at the end of the maul (additional weight and longer/larger diameter maul heads) to make one that I like for that purpose. One of these days I will get a metal lathe and turn some brass to replace the washers at the end of the maul. The washers work great when prototyping because you can keep adding weight as you test them. A lot of the poly heads are HDPE (High Density Polyethene) and some are UHMWPE (Ultra High Molecular Weight Polyethene). I have not seen much HDPE in black rod form but I have seen UHMWPE and ABS in black a lot. Both of them also come in White and sometimes green. I have a sneaking suspicion that Bob's might be ABS Machine Grade Rods like Lustran 752 or Polycarbonate like Hydex 4301. It most likely is the ABS due to the Rockwell hardness and a fairly high impact resistance. I would have to look at them to see because it has been quite a while since I gave mine away. When I was looking and selecting rods for the heads I looked at 3 specific properties to gauge it by. The hardness (Rockwell R or Shore D for plastics), density or specific gravity and impact resistance (specifically notched izod due the the edges of tools sometimes striking at less than a 90 degree angle). The three that I considered were Lustran 752 (ABS), Hydex 4301 (Polycarbonate) or UHMWPE. Here's the three specs for them. You notice that UHMWPE has the best overall impact resistance but falls behind in hardness to the Lustran ABS. However a 69R for hardness isn't too shabby either. The Lustran has the highest hardness and the 2nd highest notched impact resistance. Either one would be a good choice but I would stay away from HDPE because it is about 10R less and it's notched izod for impact resistance is low at 1.5-3. Regards, Ben P.S. Probably more than you wanted to know about plastic rod!!!!

-

rdb, We have used some of the polymer clay for very weird shaped molds several times and you are correct it works quite well. I haven't tried paper mache but would think that applying a finish over it after it was dry would keep out the moisture. I never would have considered concrete. When we do concrete countertops and such we build molds or forms for them rather than using them to create a mold....different thought...Uh-oh. Regards, Ben

-

Ray, I have used birch plywood for some molds and I use polyurethane on it to keep the moisture out of the layers of plywood. When I first used those molds, I did not apply a finish to them and they started to delaminate over time. All the later ones definitely had a finish on them. I also use a lot of used plastic cutting boards. I used to go around and pick up the used ones from various thrift shops and I used them for molds and our initial maul heads (no longer use these for maul heads but I do use stock poly rod for them now). Now a lot of people around give me their used ones and I get a care package every so often of delrin and other plastic cutoffs. If I have a special shape I generally rough cut it on the bandsaw and then use power tools to shape it to its final shape. Nice thing about these is that they don't absorb moisture. You can make an inner and outer mold quite quickly. Regards, Ben P.S. My son broke the keyring portion of his alarm system and we made a piece mold for this one (inner and outer). Total time for mold making , drying, hand stitching, edging and finishing was a hair over three hours. Drying time was the longest factor (almost 1/2 the time). A heat gun would have helped to dry it. He could have spent a little more time on the cutouts but.......

-

Unfortunately mauls is something that my son and I played with qute a bit when we were testing and trying what we liked best. We probably gave away 10-12 mauls with exotic wood handles and 3-4 leather handled ones to people that were starting out. We have several of Barry's, a Maul Master , a Stohlman and many handmade ones. I prefer the poly hands down to the rawhide because as Bruce Gibson so accurately stated "....Rawhide peels and flakes like a sun-roasted tourist." I haven't tried one of Wayne's either. it was interesting to hear Bruce Johnson's choices.... I prefer the tapered on for because it allows me to tool a little longer without feeling as tired. The reason being is that my elbow is slightly lower and I don't have to expend as much energy (simple biomechanics). The one that we use for stamping larger basketweaves and geometrics has some extra weight added to the top end of the maul. We have also going to try a maul with a larger diameter piece of poly. Bruce is right...test and try to see what you like. Bob - Which one did you like so much? Regards, Ben

-

Conway buckle as adjuster buckle on shoulder strap

gtwister09 replied to Troy1's topic in Hardware and Accessories

-

How do I sharpen the blade on splitting machine?

gtwister09 replied to ruthless's topic in Leather Tools

This guy has some great ideas on sharpening and it is very well researched. Beach Sharpening There are a lot of different areas to read about. I like him a lot because he is ALL about jigs and the repeatability. In my research, I talked with a couple of tooling and grinding experts who I worked with in the past that perform cutter tool and grinding in a large manufacturing site. They were impressed with his work and his research. They knew that I was not a great fan of microbevels in sharpening but I also can't argue with the data that they have compiled over tens of thousands of hours of tool monitoring comparing with and without microbevels. It cuts thier sharpening time dramatically and yields a slightly longer cutter time. The time was not that much different but when using CNC machines that time counts because setup in a holder and checking it on a digital comparator takes time. So if they can leave it in a little longer it adds up over time when you are discussing thousands of tools that are used in their high speed machining environment. I have used it for plane irons and chisels but will have to modify the setup to use it for my 10" splitter blade. I was also thinking of using a setup for my smaller planer blades as well (12-1/2). Instead of having all three cutting surfaces together I will have to make it where I can do one at a time. Enjoy the reading... Regards, Ben P.S. As Bree said BE CAREFUL!!!!! More than one person has cut themselves on these blades. -

Ryan, That one's nice. It looks like Kamloops was a great place to be to see some great saddles. Regards, Ben

-

Darc, Great photos. Great lines and flow. Great saddle. Thank you for the additional photos. I really like the combination and placement of tooling and neutral space on this saddle. Once again.... CONGRATULATIONS! Regards. Ben

-

Gordon, Very nice modification of Ole George! Regards, Ben

-

Congratulations to both of you! Well deserved I am sure. Post some pictures for us to admire. Regards, Ben

-

My latest saddle...number four for me.

gtwister09 replied to Elton Joorisity's topic in Saddle & Tack Maker Gallery

Elton. Nice looking saddle and congratulations on the win! Regards, Ben -

I think that he also did one of the 2007 LCSJ covers. I believe that it was either the July/August or September/October one. I will have to look and see. Regards, Ben