-

Posts

972 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by gtwister09

-

Where is the "View new posts since last visit" ?

gtwister09 replied to TimberWolf's topic in Feedback and Suggestions

I was reading about this upgrade and here's a work-around that has worked so far for me. Click on the View New Content and it will generally say...sorry. Click on it a second time and it will give you your new posts to view. Only one time it hasn't worked. Hope that helps. Regards, Ben -

day planner

gtwister09 replied to bran7347's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

bran7347, I would agree with what Bob has brought out. It does look good for your first one. It almost appears that the basketweave is too steep for this piece but that again is a personal preference. When you get a basketweave too steep or apply it horizontally or vertically then any small variance shows up more distinctly. A flatter angle tricks your eyes to some degree. The checkered borders do jump out at you as well as the almost straight corners. Another item was the lines that extended past the borders on the basketweave areas...almost into the edge of the planner on the top. One of the other things that jumped out at me was the sunburst in the corners. It would have been much better to not have the overlap that you have on those. In fact if you look at the top as an example you could have placed the first sunburst tight into the corner where your small seeder is at. This would have filled the space for the vertical portion as well. Likewise the bottom has the same issue. If the sunburst spacing isn't going to work out I usually leave about 2" or so and lightly measure out my sunbursts to determine if I need to tighten them up or spread them out a little in order to fit the remaining sunbursts into the space. Your starting on either side of the scallop in the midle was an excellent choice for starting the sunbursts. These are just little things that can help the next project.. Regards, Ben -

I haven't talked with Duey for a few months but here's the latest email address that I have from him in March. Duey's email address Hope that helps.... Regards, Ben

-

45 WINCHESTER AUTO BULLET Leather Adjustable SWIVEL KNIFE

gtwister09 replied to manuelKOS's topic in Old/Sold

Interesting twist on a swivel knife. They do look nice and well built. Regards, Ben -

Thanks Gary and Lucas! One for one... Lucas what type of pigskin did you use specifically? Regards, Ben

-

Care and Maintenance of Display Saddles

gtwister09 replied to Curbstrap2's topic in General Saddlery Discussion

That's too funny!!! -

Very nice knife and sheath. Very complimentary to one another.. Greta work. Regards, Ben

-

Rob, WOW! Somehow I missed this. I am with Alan on this....that is a lot of braiding. Regards, Ben

-

Lui, It has been awhile. Good luck with your new endeavor. Regards, Ben

-

Bob makes some great points about material selection. Matching them to the customers use is important. Mesquite thickets are awful unforgiving. I have seen a new pair of elk skin chaps be eaten up by the thorns (not to be confused with chromed elk skin) in a relatively short amount of time. Regards, Ben

-

Care and Maintenance of Display Saddles

gtwister09 replied to Curbstrap2's topic in General Saddlery Discussion

Bruce gave some good information... Instead of the WD-40 for the iron hardware, we have used another one called Strong Arm Spray that appears to work much better. Strong Arm Sprays Regards, Ben -

Bree, I believe that looks more like Asian Satinwood but I may be wrong. Ofcourse it may be a lightly figured curly maple but I know Ed has used the Asian Satinwood before. Ed may be able to cast some light when he gets in... Regards, Ben

-

airbrushing finish

gtwister09 replied to brinyar's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Scott, I like the matte finish. Thumbs up from me on the weep or "drain" hole...but that's just my opinion. It's unique. Regards, Ben -

Steve, Slick 9 - good marketing name. As others have already said it looks nice. Lots of shadows... One big shadow on the lower left...??? Nice work. Regards, Ben

-

Nice work and stitching. Unique idea on the the use of stingray on the eyes in the skull. Any issues with sliding across the skill and catching as you slide across? I saw what appeared to be some stitching hidden in some of the skull features. Regards, Ben

-

Storm, Send Ed a personal message and ask him about a mallet. He does do nice work... Regards, Ben

-

Getting the spacing and alignment right with letter stamps

gtwister09 replied to UKRay's topic in How Do I Do That?

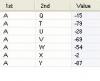

Ray, One of the major problems with the idea of reworking them is that it will still require different spacing for certain letter combinations (kerning pairs). If you open a font and look at it's metrics specifically its kerning pairs (for capitals only in this case), you will see different numbers for every combination. For instance an "A" and a "W" require a whole different kerning pair than say an "A" and a "X". For instance common ones for the "A" might be Q,T,U,V,W, and Y. In some instances you might have a slight tightening for an X. These numbers are how far you need to move the letter from the edge of it's bounding box. The bounding box is equivalent to the edge of the square portion of the letter stamp. Here's an example of what I am talking about. The negative numbers denote a tightening between the two letters. Regards, Ben -

Paul, As a LONG time customer of yours, welcome aboard! I look forward to your new information. Regards, Ben

-

I have seen a couple of advertisements for pigskin wrapped horns on some Wade saddles and was wondering about them. Last night I was reading an article in the Western Horseman and saw a saddle in the article with a pigskin horn wrap from Big Bend I believe. I was wondering a few things about them.... How many have used them before? If you have used them what is your opinion of them all around? Your likes/dislikes, pros/cons and any information you would want to share. Regards, Ben

-

Bob, Great looking chaps! Love the tooling as always. Great detail on the double stitched seam, Elton did a great job steering and mentoring you out of trouble from the looks of it. I like the inset detail. Regards, Ben

-

Bob, A lot of people swear off of draw gauges because just like plough gauges the blade needs to be beveled more or less on the side nearest the guide. There are just as many gauges that bind up as wander. Beveling more as in the case of Bob (Jim gave this tip as well) allows the leather to pull up against the guide and preventing the blade from coming out of the material or wandering. The outside bevel in this case generally has little impact on the gauges. Now for caveats when sharpening to fix a blade (SOMETIMES the gauges are garbage and no amount of tweaking the blade fixes their wandering or bunching ....... GET RID OF THESE ASAP). This is not a fix for every gauge (draw or plough) but can help if the problem is slight. Excessive (or let's just say "too much") bevel on the blade facing the guide will likewise make the leather gather and bind against the guide. This will make the work difficult if not impossible to get through the gauge.Too little as already discussed and blade will wander.A good rule of thumb for any blade is increasing the bevel will make it dig deeper. Likewise shortening it will make it rise. As in the case of the gauges increasing the bevel on the blade side towards the guide will make it bite deeper. Only do that if it is wandering out of the material. Likewise as stated above if it binds against the guide (biting too deeply) then decrease the bevel. I generally only add or subtract bevels about 1/64" at a time and test. Several draw gauges that people said were garbage and one plough gauge were fixed in a matter of 10-30 minutes with one or two tweaks to the bevel of the blade. One such plough gauge was an old Barnsley in VERY GOOD condition and it had been given to this guy. Anyhow he brought it to me to trade because it was a piece of garbage (his words). He sold it for $25. I looked at it and asked what he intended to do. He wanted to get something to do belts and other strap work. I asked what his issue was with it and he said "It was a bear to pull any straps through. Worst design he had ever seen...his wooden one did better". I tested a strap and lessened his blade bevel by 1/64" and SHAZAM it slipped right through there next time. He was sick and upset at that point. Needless to say I told him how to keep it tuned up and got my $25 back. Too bad it was a GREAT plough gauge. Regards, Ben

-

I too had a couple of the Procrafter series tools bend. Bob's warning is not without merit. Good luck. Regards, Ben

-

Jim and Dan, Great family history and horse. Welcome aboard. This is a great site as you will find out soon enough. Regards, Ben

-

neat-lac

gtwister09 replied to dustin29's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

They do carry it and yes they don't have a lot of their items on the web page. Just give them a call. Regards, Ben -

neat-lac

gtwister09 replied to dustin29's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

Panhandle Leather in Amarillo carries it. Panhandle Leather Regards, Ben