-

Posts

850 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by MtlBiker

-

@chuck123wapati Thank you for the good info! What's your opinion of this Japanese water King Water Stone Set? That plus maybe a rougher sandpaper for initial forming and a strop for polishing? When you say you use various sandpapers for the "finish sharpening" do you mean at the end after you've used a stone? I think you told me in another thread that you don't use a strop for polishing. Oh, I don't use the stones in the photo I posted, at least not in the last few years but they have been used in our shop for close to 50 years. Various employees have used them for sharpening all kinds of things. I have no intention of using them for my leather cutting tools. That's a kind of sharpening stone?

-

I started off looking for an oil stone for sharpening my new round knife (should arrive hopefully by tomorrow) and I'm totally confused by the vast choices that are available and I have no idea what to get. In my company workshop (picture framing shop) we've had a couple of oil stones for probably 40-50 years. They work fine for what we use them for. But I want to equip myself with what I need to keep my leather cutting tools sharp which I'll keep at home where I do my leatherwork and sewing. I guess I need something for getting a rough edge on a new blade in better shape and then something else for fine-tuning the edge and getting it razor sharp. And a strop (which I've got ready) for polishing the edge. I found Arkansas Oil Stones in medium, fine and extra fine grits (no actual grit value specified, but they recommend both the medium and extra fine) at Lee Valley tools. Then I find diamond grit stones and also ceramic stones and even green silicon carbide. Totally confusing. I don't want to go overboard, but I want to learn how to and then maintain my leather cutting tools properly. What would you suggest as a minimum to get me started? Thanks very much. Here are the two oil stones we have in our workshop... they are the only oil stones I have any experience with.

-

After I print out my pattern, I do glue it to the template material. Because often there is other information on the pattern that's handy to have right on the template, such as where holes need to be punched, where other components align, etc. Plus with the pattern glued to the template material, it's a lot easier to cut it out (at least for me). Now, several months after I started this thread, I still find my favorite template material is the Plugghast from Ikea. Thick enough to cut against (with some care) yet easy enough to cut out my pattern. And not expensive. (I haven't found a dollar store cutting board to be big enough for my needs.)

-

I have a Sailrite Ultrafeed LSZ-1 (Premium) machine and I love it. I really didn't think I'd have much need of a zig-zag machine, but I'm surprised at how useful that feature actually is... Even if I'm not making zig-zag stitches, being able to move the needle position left, center or right within the presser foot is a great feature. It makes it really easy to sew zippers (without changing the foot) and using the presser foot as a guide, just by the needle position I can get my 1/8", 1/4", 3/8" and 1/2" seam allowances without any other guide. I did change from the rather aggressive sawtooth presser foot and feed dog to their "knurled" set and for leather that's much better. I generally use v92 thread but Matt Grant (of Sailrite) assured me that the machine would have no problem with v138 thread (top and bottom) as well. But I haven't yet tried that. With the current motor, I have no problem sewing through three layers of 7-8 oz veg tan leather with the v92 thread. With the addition of their new WorkerB servo motor system and speed control the machine will have even more punching power and be even easier to control at slow speed. I'm in line for one of their earliest shipments of the WorkerB upgrade. My only nit with the machine is the rather small domestic size bobbin. I wish it had a bigger bobbin. And Sailrite's service and support, both pre and post sale are outstanding! And their tutorial videos are super helpful and very well done. Oh, a couple of months after buying the LSZ-1, I added the portable folding table they sell for the machine. I love the combination!

-

Thanks Klara. That's what Chuck said... that using a strop is more like polishing than sharpening. I've just make a couple of strops to try out... one each of veg tan with flesh up and down, and one each of chrome tan, up and down. My Green Chromium Oxide and round knife should arrive next week, so in the meantime I'll be checking out the numerous YouTube videos about stropping and of using a round knife. Cheers!

-

Thanks very much the the fuller explanation, Chuck. I appreciate it. I'm going to pick up some 2000 grit sandpaper. Do you use the sandpaper dry or with something to lube? "...it would be with the right stuff and not whatever is laying around..." What IS the right stuff? I have veg tan leather and some chrome tan. And I've got to order most leather online and I really don't know what to look for, for use in a strop. I will certainly be experimenting with various materials and trying my best to learn the techniques. Thanks again!

-

Interesting. So you don't use a strop at all? Just the 2000 grit sandpaper? In terms of leather hardness, I really don't know what I have. I've got some veg tan and some remnants I bought of chrome tan. The chrome tan feels much softer than the veg tan, much more flexible/pliable. The veg tan is stiff. Is hardness of leather something else? As a novice, I really don't know. But I'd want to use a piece of something I already have instead of buying leather specifically for making a strop. Anyway, I guess I'll make something, maybe one of each, and see if I can learn to use it properly. At this point of my inexperience I probably wouldn't be able to tell which is better. In another thread here about round knives, etc. I was told multiple times that I'd have to strop the heck out of my new round knife and that when the knife arrives it wouldn't be sharp enough. But I'll pick up some 2000 grit sandpaper too... here at work the finest we use is 400. Thank you for your comments.

-

Funny, but that's what I was thinking also... that I didn't want to waste "good" leather. Merci beaucoup!

-

I'm about to make some strops, but I don't recall ever having seen one in real life (unless as a kid, I saw a barber sharpening something)... I have some pieces of veg tan leather and some that are chrome tanned. Would either work equally well? I'm talking about using the flesh side for sharpening and gluing the other side to plywood. I've also ordered some green Veritas Honing Compound. Thanks.

-

That Lee Valley flexible curve looks like it'll work well. I actually had one, oh maybe 30 years ago, but have no idea where it's disappeared to. I'm going to order one of those. Thank you. (Funny, I usually use a VPN, and with it active the Lee Valley site was blocked for me. Turning off the VPN allowed me to access it. Guess they don't want anyone who is not in Canada to access.) Do you think you could cut against that flexible curve? Or would you use it only to trace the curve onto your material? This is the kind of curve I would do most often... Using Bezier curves in a drawing program allows me to fine tune the size and shape exactly how I want. But of course the resulting paper template cannot be used to cut against.

-

Thanks for the tips about the sharpening. We use a fine whetstone at my work to sharpen tools but I've never used a strop. I guess I'll have to make/buy one. I do regularly sharpen my pocket and camping knives, as well as chef's knives. So I expect moving up to a finer edge and strop won't be terribly challenging. Can't help but laugh though, about making a sheath for the round knife... It reminds me of an old Harry Belafonte song, "There's a hole in the bucket, dear Lisa, dear Lisa..." The song goes on and on about what should he use to fix it, then how will he cut it, how how will he sharpen the knife, and the stone is too dry, and Lisa says he should wet it, which brings us right back to the hole in the bucket. I guess you'd have to hear the song to see the humour. Anyway, what should I use to cut the sheath for the round knife? Here's a link to a really old YouTube video of Dear Lisa. Cheers!

-

Believe it or not, I just ordered from Barnsley direct. Their shipping to Canada is quite reasonable (even less than Amazon US sometimes charges) and I'm getting the Barnsley Saddlers Round Knife, a Narrow Skiving Knife and Extension Clicker's Handle with curved blades. That should be more than enough to get me going with cutting leather. And it should arrive here before the end of next week too! Now to watch all the YouTube videos I can find about using these tools properly. Thanks for the recommendation.

-

Did it take long to master the round knife? I can see that it should make cutting curves easier, but I'm surprised at your statement that with one you can also make long straight cuts without a straight edge. Surely you couldn't make two long parallel straight cuts, like for a belt, without using a straight edge as a guide.

-

Couldn't find the knife in Canada with a Google search, but Amazon US has one. Is this the one you use/recommend?

-

I'll give those scissors a try... thanks. Funny, Amazon in Canada doesn't have the 8 1/2" version... only an 8" and a 9 1/2" (both Red Dot) version. I'm going to order the 9 1/2" version, thinking the extra length might give more leverage for thick materials. A "plate, a bowl, a lid, anything that has the right curve to it" just didn't appear in my kitchen or garage. As you can see from my first post photo, I needed to round the top of the flap in a shape sort of like a tongue. I found the easiest way to get that shape was to make a bezier curve in a drawing program. But of course the resulting paper template couldn't be cut against. I found it very easy to cut out the paper template using scissors, so your suggestion of a good pair of scissors to cut the leather might work great for me. Thank you!

-

I've got really good Gingher fabric scissors which I've been afraid to use on leather in fear of ruining them. I guess leather scissors are different. To get my curve pattern I use a drawing program on the computer and form a bezier curve exactly as I need and print it out. Then cut it out (using paper scissors ) and position it carefully on the flesh side of the leather. I don't use a pen to mark it but rather just an awl, which leaves an easy to see line. Follow the line to cut however, has been challenging for me. Scissors would probably be easier.

-

Yes it helps. Thank you. Time isn't really a factor... but two months for delivery is pushing it. A week, no problem, even two, but two months?? I found the Osborne round knife in Canada (Quebec) and I linked the site a couple of posts up. Aaron Martin wants 50% more for the knife PLUS shipping than Cuir Desrochers. I was going to order that, plus the skiving knife, but they're out of stock on the skiving knife so I'm holding off ordering for a week (still better than two months!) until their supply arrives. @PastorBob - That's really great! Thanks very much.

-

Thank you! I found that exact same knife on the Amazon Canada website but it says delivery estimated to be Nov 5th to 18th!!! (But I want it NOW!!! ) The search goes on... I found a supplier (not quite local but in Canada) which has two different Osborne knives... one is called a 5" Round Blade and the other 4 1/2" Head Knife. From the photos (especially as a novice) both knives look extremely similar. Can you or someone else tells me what the difference might be and which you'd recommend? Both are the same price. They also have an Osborne Skiving Knife but the width isn't specified. Their product code (might not be Osborne's) is MR-469a. The website is: Cuir Desrochers

-

Thank you! Now I know what that kind of knife looks like. Too bad it's sold out - I'll try to find one here in Canada.

-

Your (and other) reply have steered me away from the Stohlman round knife. I'll see if I can find Osborne knives from a supplier here in Canada. Another vote against the Tandy. Thank you.

-

Great reply... Thanks! As I said, my last attempt was with a utility knife. I use knives like this all the time at work (framing shop) but I still found it next to impossible to cut an even curve on the leather following my outline. I will check out clicker knifes. I'm sure using a round knife would take a lot of practice, and I was ready to buy one, but thank you for steering me away from that Stohlman knife. I will search out those videos. I have one of Nigel Armitage's books (most recent one I think) and he shows a photo of a round knife but doesn't talk about how to use it. Cheers!

-

Thanks very much for that link! Can you possibly point me to what a "flat bladed Japanese" knife looks like? A Google search shows up hundreds of Japanese knives. I'm not sure what you mean by "flat bladed".

-

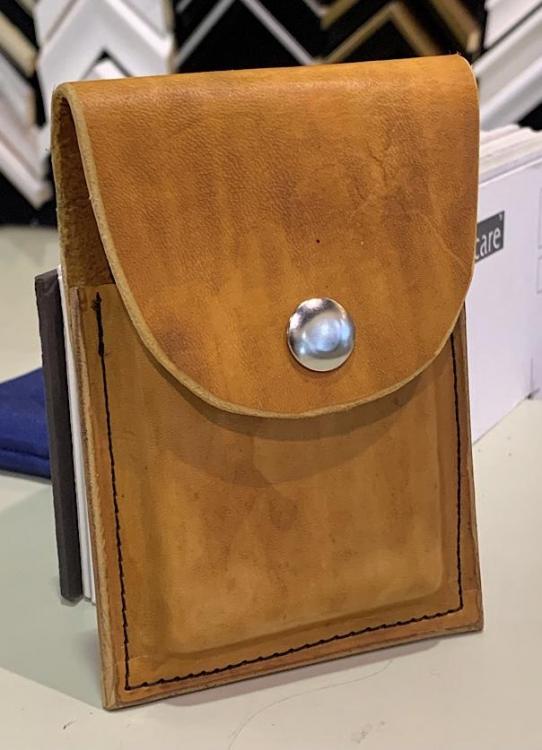

I'm very much a novice with leather work and I've been trying to make a little belt pouch to hold a "Secrid" metal credit card holder. What I'm having particular difficulty with (besides making straight stitches) is how to cut the curve on the top flap. An x-acto hobby knife (#11) is just too flexible. Better is the 18mm utility knife with a carbon blade. Better, but not good enough imho. Are those curved knife blades good for cutting curves? I'm thinking of this one from Tandy: Al Stohlman Round Knife. Would that make it easier to cut a smooth curve? I'm thinking that you'd rock the blade back and forth, cutting off bit by bit of the leather. Any suggestions would be most welcome. This is my latest attempt... far from perfect but getting better with every attempt...

-

Maybe if you add some rice and maybe a cucumber raita.

-

Nice! (But what's the "804 RNR" refer to?) The part where the money clip is installed... is the leather doubled there (so that the back side of the clip is inside) or what? Your photos don't show that part. Have you done anything with the edges of the leather? Beveling, burnishing, etc? (I'm trying to learn what to do.) I really like the distressed look.