-

Posts

189 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Thescandall

-

I’m going to try wiz’s setup before I drop some funds on a smaller machine then. I wish I could get my hands on some kangaroo leather lol.

-

Thanks wiz. Good read and seems like a good used machine might be in order. Most of my work is on thicker materials and I’ve got it stitching great as it’s set up. But the wife is coming up with things to make that are thinner.

-

I have a 23 in 704 as well. The specs sat the 5100 will sew down to #18 needle. Your right I need some smaller thread for those needles tho. I think 96 or something. Suggestions would be great. I only have about 11” of stitching with it under my belt. I want to do some smaller stuff like wallets and ladies. wallets.

-

Hey Rocky Tracking says my narrow feed plate and dog are actually in Houston now. Should get it in a couple days. I’ll give a report on the fit and function soon. I got some small needles. #19 and #21 and some #138 thread. Installed the drop down guide and put the left side presser foot on getting ready for it.

-

My first gunbelt

Thescandall replied to Thescandall's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Not yet. But it’s on the list. -

My first gunbelt

Thescandall replied to Thescandall's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Broke a needle in the middle of stitching the buckle loop on. Really freaked me out. But it was thru 4 layers. Defiantly learned a thing or 2 on that one. -

My first gunbelt

Thescandall replied to Thescandall's topic in Gun Holsters, Rifle Slings and Knife Sheathes

It’s a Techsew 5100 standard. I’m really enjoying learning how to use a machine. -

Using my new machine. 5100. I have about 11’ of stitching with it under my belt now. I used Chicago fasteners for the Bullit loops. .357. 3/4” spacing on the belt and 11/4” on the strap. If I switch to .45 I can take it off, add 1/8 to the strap centers and it should work using 4-5 oz veg tanned. Everything will be copper tho. They were in the post so I’ll have to swap the stainless ones out when they get here. anyway. Here it is

-

I would like to add. Shipping here in the USA is at an alll time slow. Getting parts and accessories from Techsew Canada is taking weeks because of the truckers storming the capital. Lots of unhappy truckers over the mandates.

-

It’s still on the boat steaming across the big pond. But as soon as it gets here I’ll give a report. Looking forward to it.

-

Wiz you were correct when you said the cost was trivial. I just got a low pressure spring just in case

-

Thanks for the info. I did contact Techsew and they sent me a pdf manual for my machine and servo motor. Really helpful folks. I’ll try the adjustments first. I got one of aussies new feed dogs and narrow cover and a left side presser. I also got 1 of the drop down guides and watched ewu’s video on how to drill and tap for the bracket. I’ll get her set up and stitchen the way I think it should soon.

-

I know there is an adjustment somewhere. I bought this machine used and didn’t get a manual with it. I’m sure it’s a simple thing. There is the big screw on top, which way makes the feet have less pressure and for the walking foot in the middle, is there a tension adjustment. video would be nice. But!!!

-

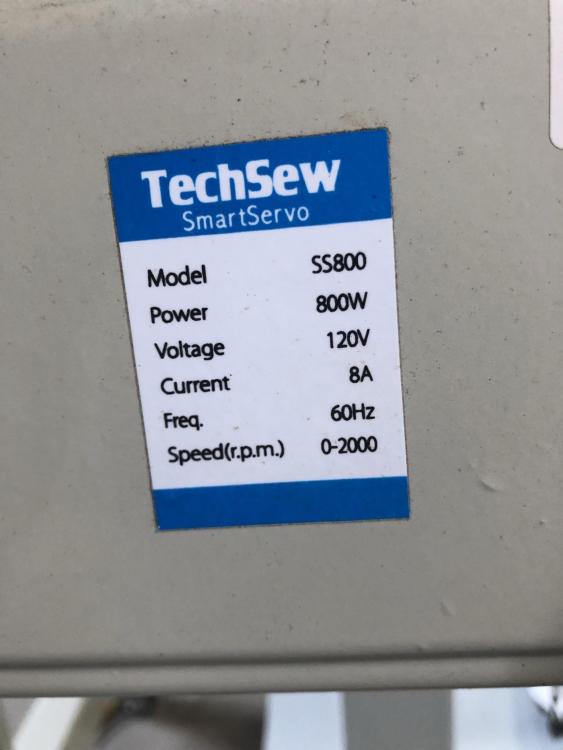

Techsew smart Servo Motor manual

Thescandall replied to Thescandall's topic in Leather Sewing Machines

-

I have a techsew SS800 motor on my 5100 machine. I can find no info about it on the web. Does anyone have a manual for it or someplace to download it from.

-

The fit is fantastic this morning. Other than a little crooked stitchin I’m somewhat impressed with my first go around using a machine. It’s super thick and should last as long as the 277 thread holds up. I used 9-10 oz with a 4-5 oz liner. Now I get to try ,this machine with Bullit loops. That’s my horses name. Lol. Bullit.

-

I’ve never sewed a thing in 63 years with a machine. Hands ( mostly thumbs) are getting a bit of arthritis from hand stitchin. So I bought me this machine and put it in my shop Wednesday and started messing around with it. Now I have watched every video of a 441 class machine on the net for over 1.5 years procrastinating about unassin the funds for one. The deal came around for a used one and I pulled the plug. I really have a lot to learn like, going around corners, sewing close to the edge, focusing on the needle position when turning, that kinda stuff. A lot of my problem is I’m blind. I was wearing 2 pair of Cheater reading glasses so I could see better. its not terrible tho. Not great but I’ll wear it. It’s for my personal 357. I oiled my gun and crammed it in a freezer bag , wet the leather ,then stuffed it in. Put some scrap spacers in strategic places and now the wait is on. This is just the holster. It goes in a drop down gun-belt that is in the making. I used Chicago fasteners to close it so I can open it back up later and sew the flap on the back thru the slot in the belt Oh well !!! It’s a start..