dans79

Members-

Posts

149 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by dans79

-

I tried to find one locally, but I'm in a tool wasteland/dessert. no one around here seems to fix/make anything. I looked at purchasing a new Osborne #65, or #66, but they were lighter, at 14 oz, and the face wasn't really any larger. The ball pein's head is ~1-1/4", the #65 is 1-1/4" and the #66 is 1-5/16". The big issues for me with the Osbornes was the fit and finish of the face, and the cost. I didn't think it was worth it to pay 3 to 5 times more, and still have to work on the face to make it suitable for use.

-

Last night I started converting a $10.49 big box ball pein hammer into a cobblers hammer. The first step was to strip all the Varnish and Japanning off the handle and head. The handle wasn't to bat but the varnish on the head was probably 1/64" to 1/32" thick, I had to break out the wire wheels to get it off. The face was almost dead flat to start with, so it only took a few passes with a file and coarse sanding disks to give the face a slight dome, and to round over the edge. With sandpaper and scotch-brite pads up to 600 grit, I refined the shape of the face, and removed any tooling marks from earlier steps. To finish off the face, I progressed through black, read and then white rouge on a stitched cotton buffing wheel. Its not perfect, but I'm pretty happy with it so far. Tonight I'm going to see if the head will take a decent cold blue, and I will probably finish of the handle with boiled linseed oil and wax.

-

Personally, as someone who is just getting into leatherwork, I found Nigel Armitage's video more beneficial than most of the other video's or articles I've seen/read! His round hole demonstration starting at about 5:55 was very informative!

-

are dividers and creasers used for the same task?

dans79 replied to dans79's topic in Leatherwork Conversation

Just for reference I'm not interested in anything decorative, and I will probably work almost exclusively with vegtan. -

are dividers and creasers used for the same task?

dans79 replied to dans79's topic in Leatherwork Conversation

Thanks for that bit of information. I purchased some 8" dividers from amazon. They need a little clean up, but hea they were like $8. -

As i wait for my first order of leather to arrive, I've been reading and watching videos. I see a lot of people use dividers to layout a stitching lines, but every now and then i see someone use a creaser similar to these. Are they pretty much interchangeable tools, or does one have an advantage over the other? Also every now and then I see people heating the creaser with a flame, what is the reasoning for that?

-

I know this is an old thread, But i thought i would share some good shots of the tools I just received, as I struggled to find good shots of Kemovan tools when i was shopping. If anyone wants some different shots of what I got just let me know.

-

Whats a decent japanese edge beveler and french skiver?

dans79 replied to ToddW's topic in Leather Tools

Most likely made by someone else and rebranded. I wonder who the original manufacture is. -

-

Whats a decent japanese edge beveler and french skiver?

dans79 replied to ToddW's topic in Leather Tools

I have a set (2,5,10 teeth) of 4mm round dent irons, and a V3 #1 edge beveler on the way to me from Kemovan based on recommendations i saw on the forum and other places around the web. -

that part i assumed. :-) ok, 2-1/2" or so will for sure require a hinge.

-

Sorry, I was referring to the distance you would expect the distance when closed. If I can get away with it, i wasn't going to use a hinge, just the natural flex of the wood. Thus the total range of motion will be less.

-

Custom leather stamps (video)

dans79 replied to Campleathergoods's topic in Leatherwork Conversation

A blacksmith I follow did something similar with a cheaper FDM printer.- 3 replies

-

- brass stamp

- makers mark

-

(and 2 more)

Tagged with:

-

I'm nowhere close to a master, but I've done paid work before. This is a simple side table a coworker commissioned me to make several years back.

-

I planed on making mine the type thats sits on the floor, you put your feed on. You do bring another question to mind, what's a good jaw opening distance?

-

Even though the raw materials for my maul have arrived , it's still far too cold in the shop to even think about machining it. Thus, I've been learning about stitching ponies as I know I will need one, and i have a few questions. how wide should the jaws be? I've seen them as narrow as 2 inches and as wide as 8. Is it just personal preference? what's with the 360 degree rotating base? I understand being able to tilt forward & back for ergonomic reasons, but I don't get the rotation, nor have I seen someone actually using this feature.

-

I have a propane heater and it does a good job of warming up the shop. However i only use it when the shop temp needs to be increased by 15 to 20 degrees. Any more than that, and the carbon dioxide and moisture starts to build up. The carbon dioxide is bad for me, and the moisture can cause flash rust on my tools. Usually the cold fronts only last a day or two, but this one has been going on for nearly a week and shows no sign of ending any time soon.

-

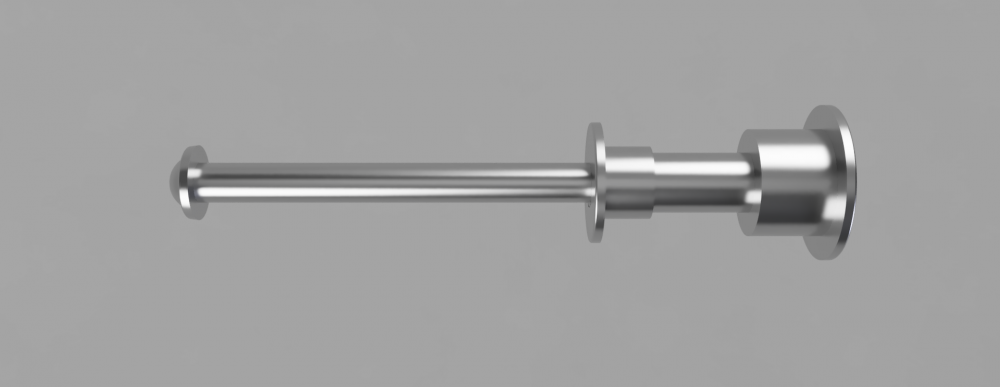

It will be a while before I can get to the maul, thanks mainly to the cold streak keeping the temperature in my shop barely above freezing, and I have another project related to my 3d printer that needs some time at the milling machine. I did turn a burnisher before the cold streak hit, here it is with some other hand tools i made over the years.

-

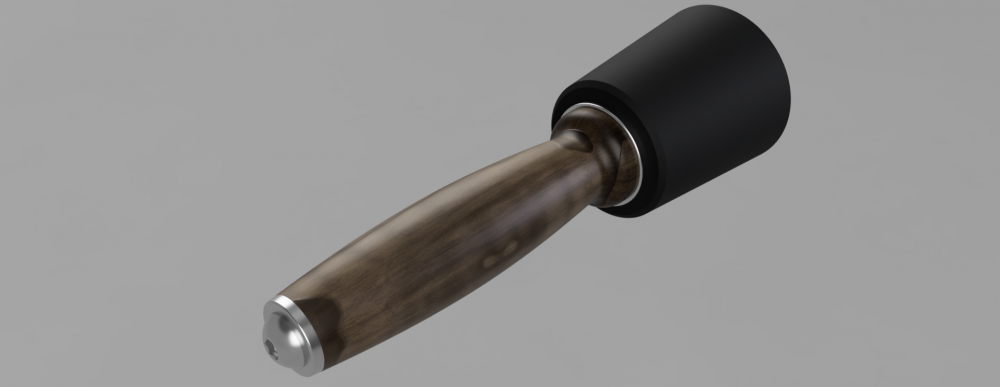

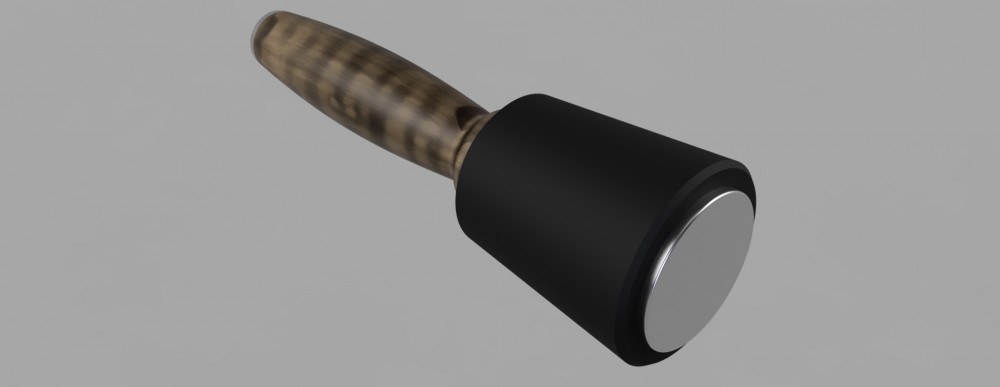

I'm just getting into leather work (still gathering tools in fact), and I plan on making my own maul. Since I have the ability to machine the various metal components to size, I have the ability to shift the balance point/ center of mass forward and back. Would it be better to have the center of mass as far forward as possible, or more back towards the handle? This is my current design.