Sham

Members-

Posts

30 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Sham

-

I have one on a treadle, works good for thin leather, shoe uppers, etc. the machine is not made for real heavy stuff anyway. Easier to control on a treadle

-

https://siska.com/services/machine-setting-dies-tools/

-

If you wanted to use a Chicago screw, you could grind it down, I do it a lot , not that hard if you have a sander, grinder, dremel

-

@Wizcrafts wow, my mind is blown, I just had a few missed stitches when I changed direction, went through an existing hole and when the bobbin was running out. I also was sewing thin leather, with a little gap between dog and foot. im actually using the foot more than the wheel. But this is an eye opener!

-

@DonInReno wow! I just assumed that should be done, damn! .. that’s crazy, I’ve been doing it for years. And was thinking the design of the machine was really not conducive to that! ok, well enough of that then, pressure adjustment only now, what do you think is a good height? Just so the teeth aren’t touching?

-

@Constabulary on a non walking foot, like 45k25, 31-20…you would sew a thin piece of shoe leather and two pieces of veg tan belt leather with the same foot clearance? I guess you couldn’t do that on a 31-20, but the concept is same

-

@Wizcrafts any machine really, but 45k25 specifically, I usually adjust my 31-15 do a piece of paper can d add life through when the teeth are at their highest. But I only see thin leather on that

-

What is the proper way to adjust foot height to material thickness? Do you make it just a little less that the material, or leave it just above the feed dog teeth? Or something else?

-

@DonInReno thanks! Yeah, I really like old black iron stuff, prefer to keep it going. Fingers crossed. I looked on eBay in England, lots of em for $200-300!

-

Thank you @Constabulary and @Wizcrafts ..,amazingly, I just raised the feed dog up and sewed with it, snd it was working well! I’m not convinced yet, but I am hopefull. I wonder if the cb machine or other clone would be close enough to swap out a feed crank? I would doubt it? I have some techsew tension parts and needle plate that I haven’t tried yet, but look right

-

Thanks @Constabulary, I think it’s #91163 but I’m not sure. They’re going to talk to me soon from the shop. Sewing guitar straps, belts, belt loop key things, shoes. I like the 207 thread

-

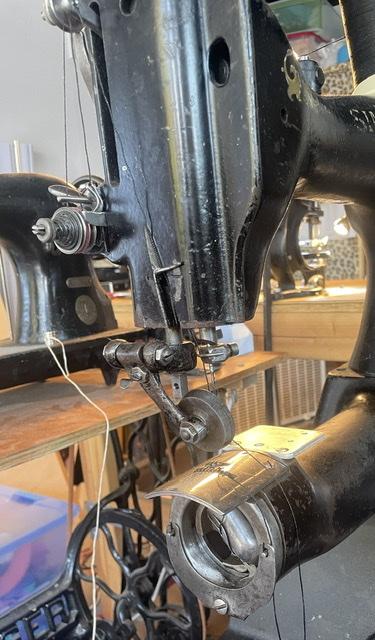

Man, I just spend a bunch of money and time getting my machine serviced, and it was great briefly, but now it only makes tiny stitches and a little intermittent. I’m airing to hear back from the mechanic, but they said something’s worn out and not holding. I think it’s the feed crank 91163, but I’m not sure. I love this machine and I’d be happy to get it going, but wondering if I should cut my losses and buy something else ? I don’t know. Anybody got some parts or recommendations? @CowboyBob @Constabulary @jimi @Wizcrafts

-

Machine is back at the mechanic, we’ll see what they say. Would be interested to hear what you say about the adjuster not going down further after lengthening slot though @CowboyBob? Also seems like it started with bigger stitches and got smaller after using for awhile

-

Thank you @jimi @Wizcrafts @Constabulary @CowboyBob @CowboyBob.. I just filed out the slot about 1/4” but the stitch adjuster piece still won’t go any lower? The motion of the feed dog looks like it would make at least 1/4” stitch, but it’s about 3/16” max, and then if I see uneven material it likes to shorten up

-

Lexol Replacement

Sham replied to Sham's topic in Dyes, Antiques, Stains, Glues, Waxes, Finishes and Conditioners.

@ScottWolf Excellent! Thank you so much, exactly what I was hoping for -

I know there has been a little discussion on this, but not much.. Lexol has undergone ownership and ingredient changes for many years. It now in the past couple few years, is completely unusable, smells like an overpowering car air freshener, leaves sticky/ oily residue, they don’t care..do weird when old historically successful companies destroy the good product they are known for. Anyway, I’ve seen a couple of msds sheets, I know it’s mostly neatsfoot oil, I tried mixing some with water, not the same. U.S. their another product that is similar? Not a thick crème or anything better but different, but like old Lexol?

-

@Constabulary @Wizcrafts ok, now it is really messed up, I messed with everything, switched springs on the tension assembly’s, raised and lowered the needle bar, foot bar, ..the timing seems ok still, but it’s now making loops snd knots on smaller stitches. I think I probably can get it back stitching thinner leather with smaller stitches. But it doesn’t want to do anything with belt leather. Here’s some video links, I’ll see if I can upload photos too.

-

@Wizcrafts, ok, I’ll see if I can make a video, and do some tests

-

Well, I don’t think adjusting the check spring did much, but I put 69 in the bobbin and top with a 25 needle and light tension through 9 oz. Veg and it worked fine, even with that tiny thread the big holes really weren’t that noticeable. Maybe. A 28 needle w/ 277?

-

Thank you @Wizcrafts & @Constabulary, I was thinking a bigger needle might do it, but 25 was as big as I had w/ 277, I did put some thin thread on top but it broke.. the check spring, I’ve never adjusted, was thinking maybe that would help, cuz I have that automatic thread regulator tab thing, that says it’s for the purpose of adjusting to different thicknesses, but I don’t really understand. I’ll go fool with it a little more

-

You would think that’s it, but the bottom tension is very light, and the top tension is so tight I’m breaking needles pulling thread through by hand..,only as a test, I’ve adjusted it all different ways. Is there any reason though that everything would change only at the longer stitch length though? Cuz it is fine at shorter spi

-

My 45k25 seems to stitch pretty well, but when I set it to the longer stitches it immediately leaves loops and knots on the underside. I’ve tightened the top tension until it’s way too tight and still does it. I’ve played with both top and bottom tensions. Tried a 25 needle 277 thread. When I move it back to shorter stitch the loops go away. …Also!…this is my post, “courtney” and I’ve been locked out, forgot password for a really long time, tried so many times to reset, and contact admin, but never get a response/email…can someone help me please?

-

After I bunch of hassle, my 29-4 still isn’t stitching right, I know the new bell cranks won’t fit, I did the brazing, maybe the motion ring is worn too, I don’t know. what about a new motion ring and compatible bell crank? Would that work?

-

Man, I’ve spent a lot of time and some money on this thing and I think it’s worse now. I did build up with brazing. But not sewing so great and only tiny. What else could it be?