-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BianVariani

-

I'm available for custom jobs such as sewing, dying, edge painting, cutting hides into belt straps, hole punching, mechanical engineering, graphic design, CNC work, Product design, 3D Printing, web design, web hosting and programming, just to name a few. I am multi-talented and well rounded. I own all of my own machines. Call Text or WhatsApp: (604) 449-0099

-

- product design

- custom work

- (and 6 more)

-

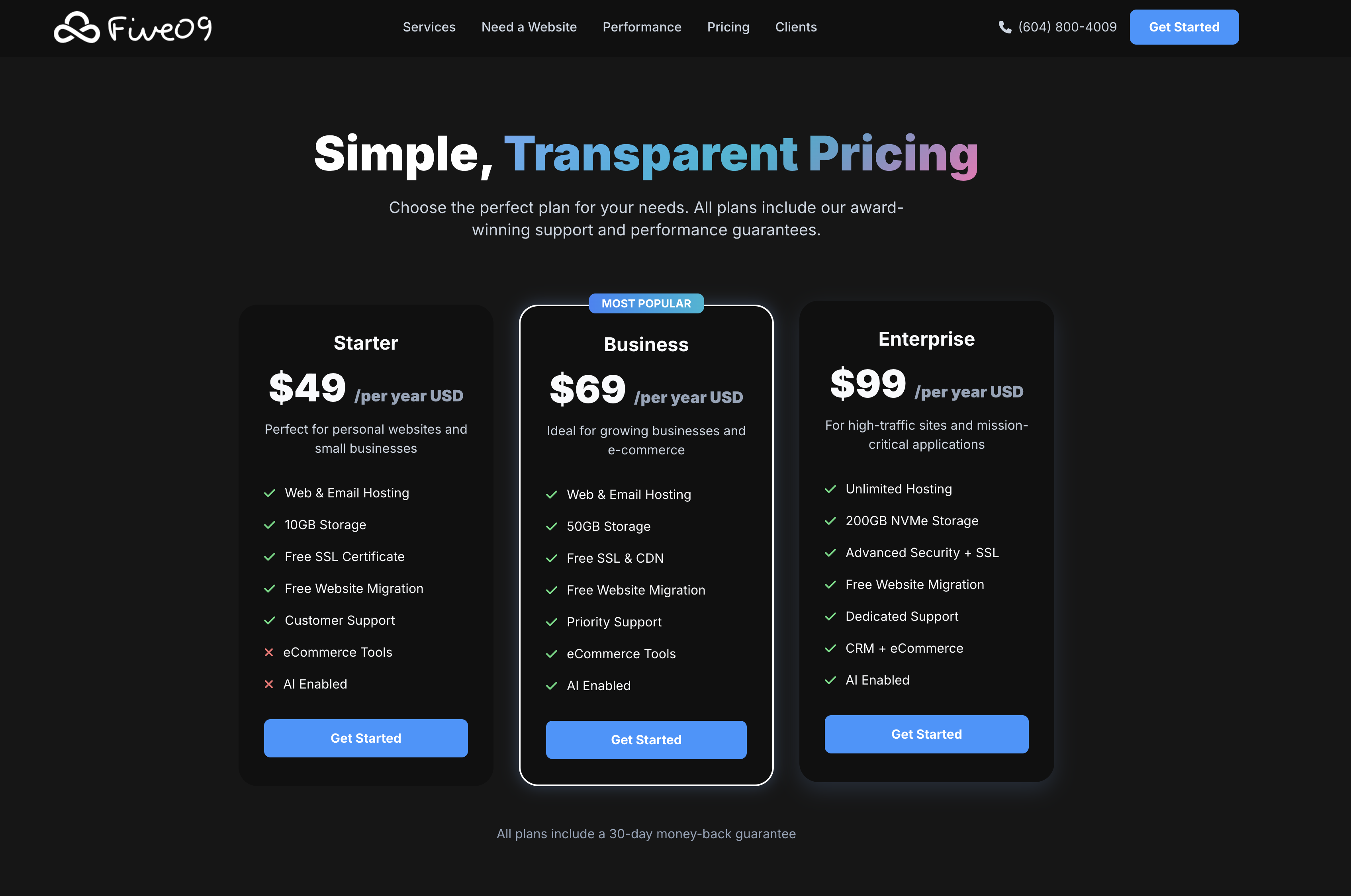

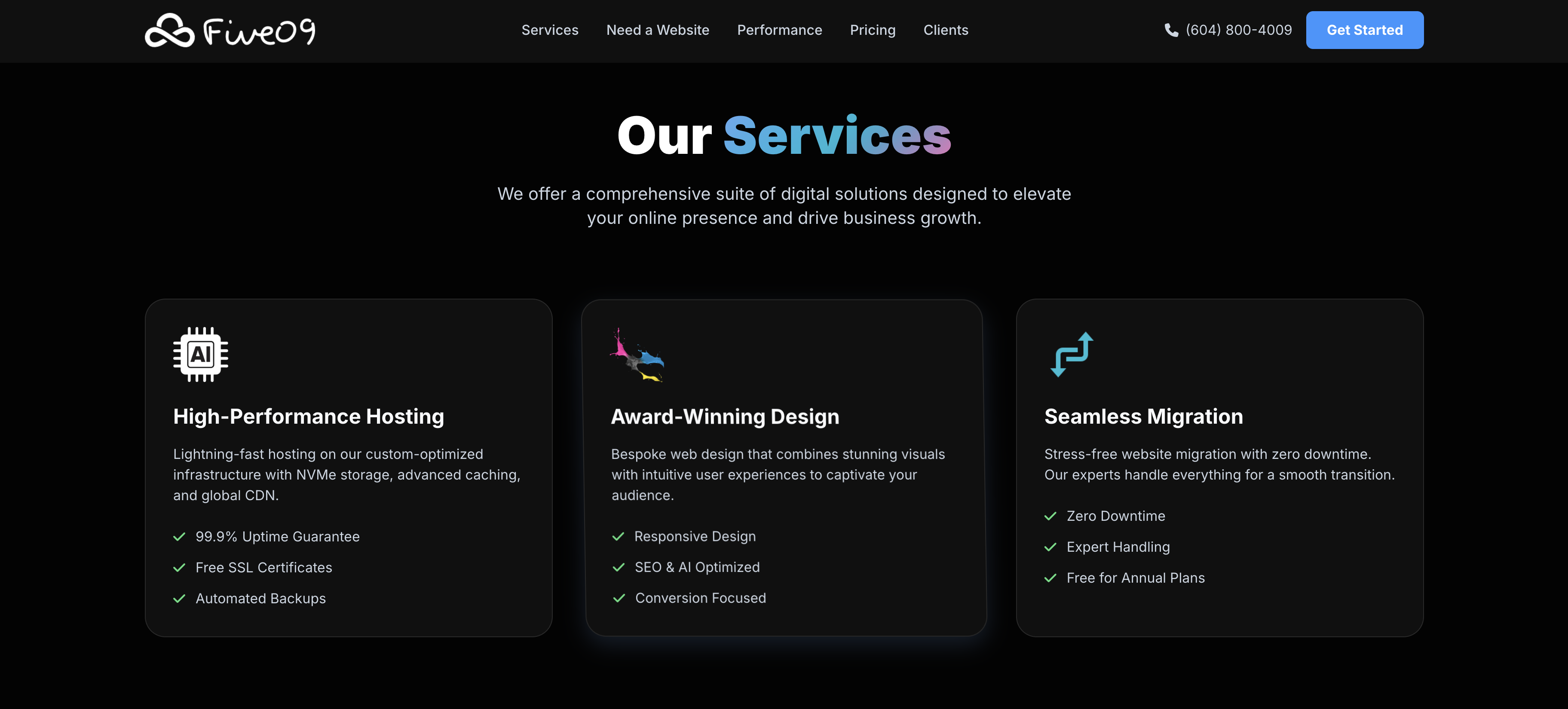

Five09.com - I offer affordable web hosting and web design services. Need eCommece, Shopping Carts, SEO, No Problem!!! Call Text or WhatsApp: (604) 449-0099

-

OMAC Leather Belt Machine for Sale

BianVariani replied to BianVariani's topic in New and Refurbished to Like New

The edit feature is not displaying for me. Please all to all of the Ads. Shipping: Worldwide - customer pays for shipping or Pickup Available -

Leather Belt Strap Cutter and Punch

BianVariani replied to BianVariani's topic in New and Refurbished to Like New

Shipping: Free Shipping - Worldwide -

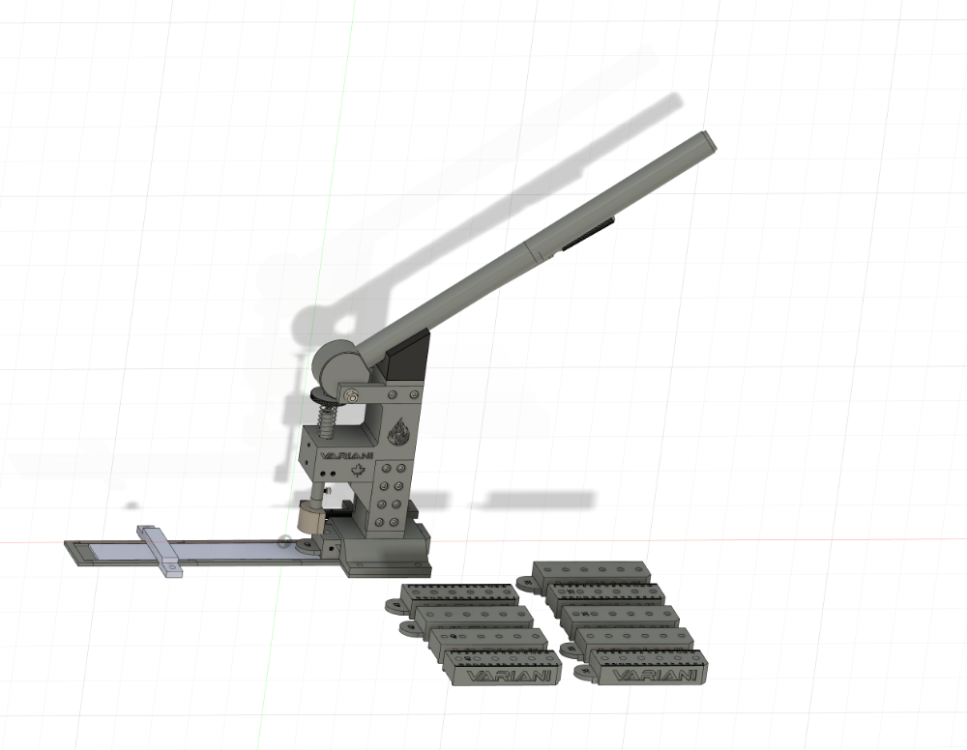

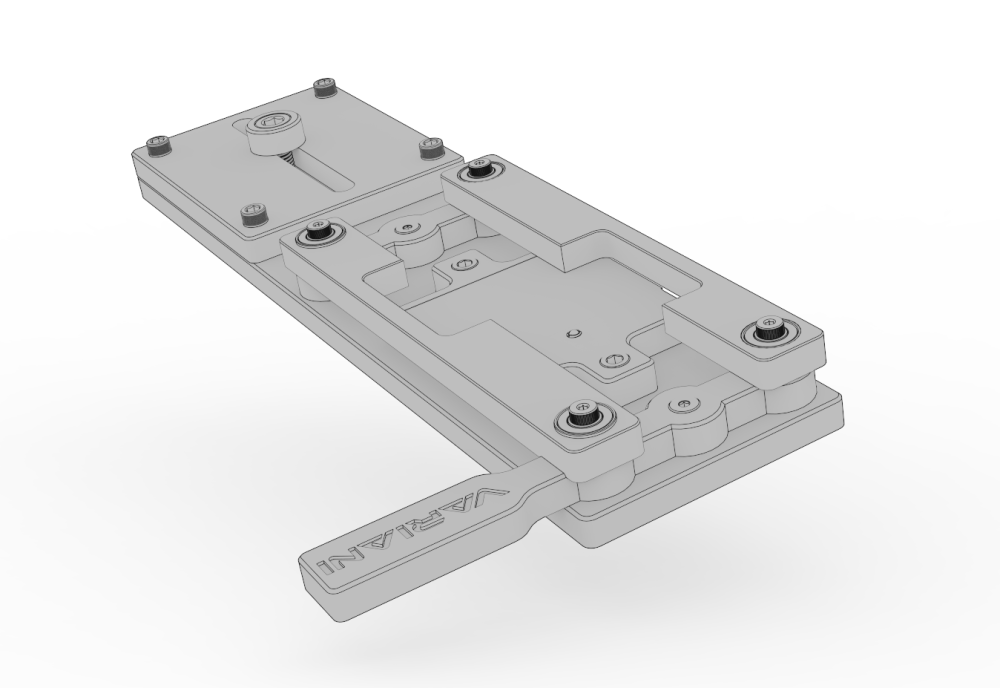

Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: 100% New - Never used - Original Box Price: $1200.00 USD Shipping: Free Shipping - Worldwide Description: Self Centering, Variani Leather belt Strap Cutter and Punch

-

OMAC 991 - Vertical Edge Dying Machine

BianVariani posted a topic in New and Refurbished to Like New

Used for 1 month, OMAC 991 vertical edge dying machine for sale. Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: Almost New - Used for 1 month - Refurbished Price: $2000.00 USD -

Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: Almost New - Used for 1 month - Refurbished Price: $5000.00 USD Description: Industrial OMAC Automatic Leather Belt Punch/Press

- 1 reply

-

- cutter

- leather cutter

-

(and 1 more)

Tagged with:

-

Almost New Omac Leather Belt Machine for SALE, only used for 1 month. Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: Almost New - Used for 1 month - Refurbished Price: $5000.00 USD Description: Industrial OMAC Automatic Leather Belt Punch/Press

-

Tandy Leather Tipping Machine for Sale

BianVariani posted a topic in New and Refurbished to Like New

Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: 100% New - Never used - Original Box Price: $600.00 USD Description: Tandy Leather Belt Making Machine. Cut & Punch Leather Belt Straps. -

I have a Tandy Leather Tipping Machines for sale. 100% New in Original Box! Custom make leather belts! Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: 100% New - Never used - Original Box Price: $600.00 USD Description: Tandy Leather Belt Making Machine. Cut & Punch Leather Belt Straps.

-

I have 25 of these Tandy Leather tipping machines for sale. ALL NEW in Box! Contact: Call, text, WhatsApp (604) 449-0099 Location: Located in Vancouver, BC, Canada Condition: 100% New - Never used - Original Box Price: $600.00 USD Description: Tandy Leather Belt Making Machine. Cut & Punch Leather Belt Straps.

-

This just cuts the belt strap tip, billet end, and the holes, not the whole strap itself.

- 10 replies

-

Please note, the design is a concept design and the cutting die would need to be added.

- 10 replies

-

Does anyone have any videos on the belt strap build/process you use?

- 10 replies

-

Share what you use? My cutter is not a commercial cutter, nor for sale, just a design for myself!

- 10 replies

-

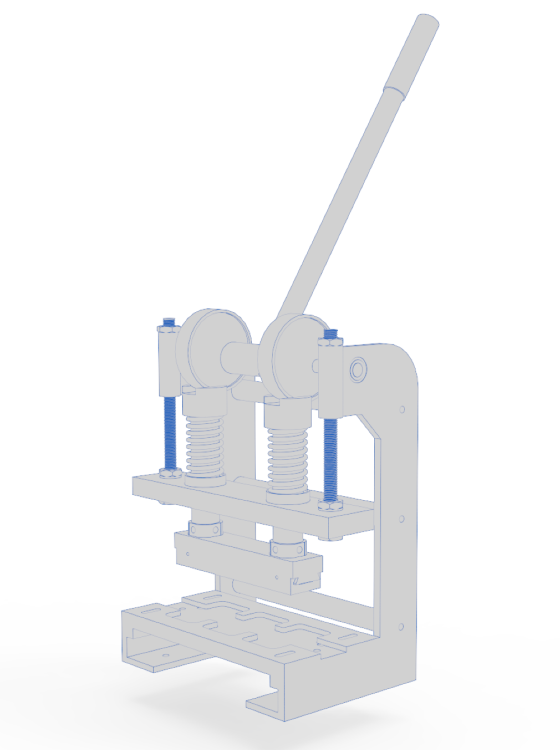

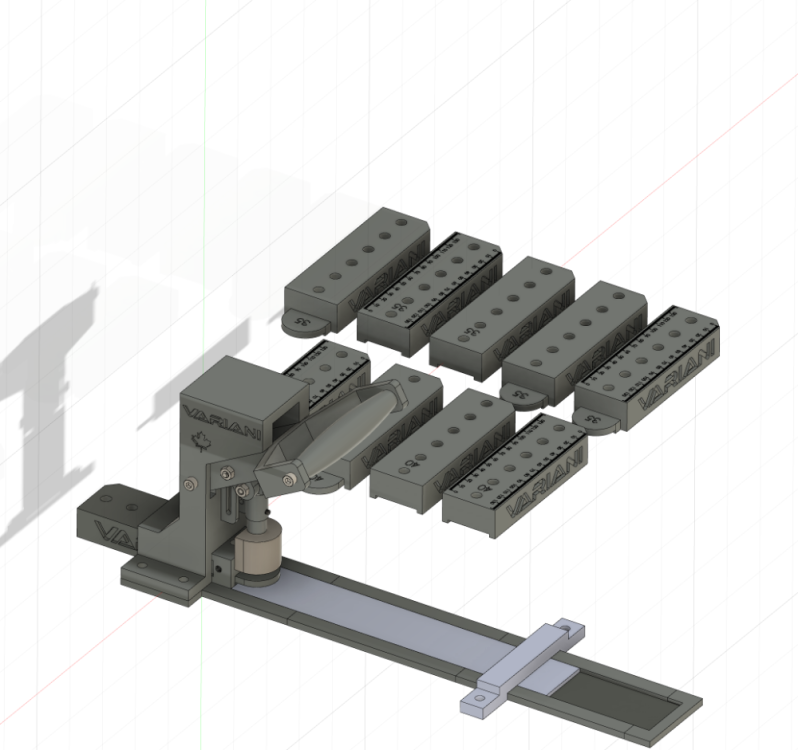

Here is a NEW design concept I have been working on to cut leather belt straps? The guides and the tooling are self centered. No Setup on tool changes, just drag and drop. What do you think? Any improvements, comments or suggestions? Please share the leather belt strap punch and cutters that you use?

- 10 replies

-

-

-

-

-

Over the past 10 years, I created all kinds of prototypes. This design went nowhere aside from using it as educational.

-

Please note that the self-centering guide is versatile and can be easily interchanged with other guides. For example, it can be replaced with guides designed for hot stamping, edge stitching, edge-painting, or precisely positioning holes in various offset locations. As I travel across the country and visit retail locations that carry my products, a common request from people I meet is whether I can make them a belt right now. In the past, I had to decline due to the lack of tools on hand. However, I have now bridged that gap, allowing me to say "Yes, absolutely!" This innovation has made my process more flexible and versatile, enabling me to meet customer requests wherever I am.

-

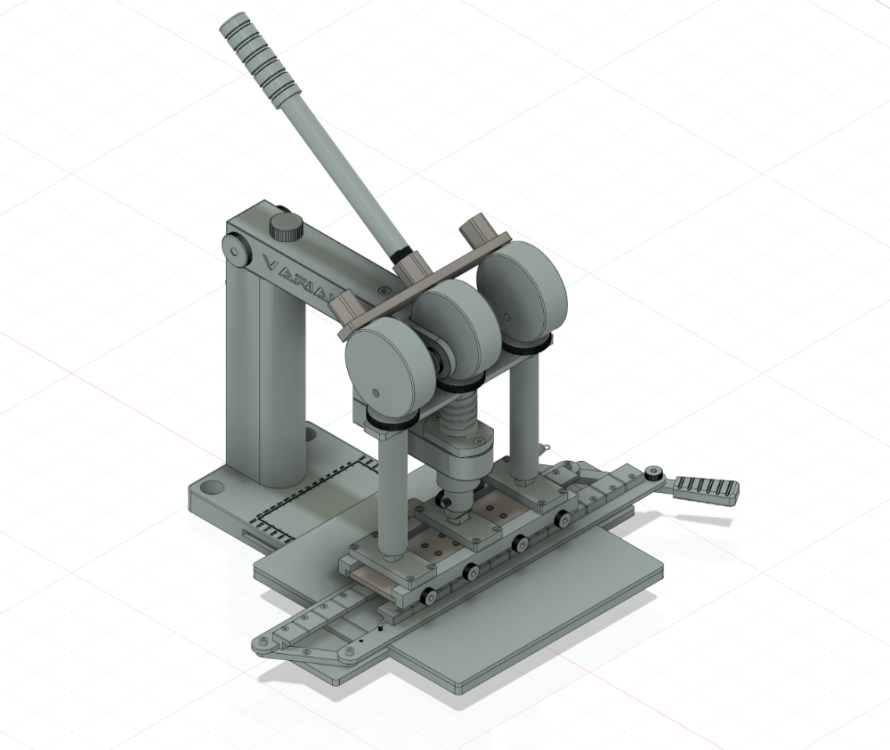

The belt hole distances I use are tailored to the belts I create. However, it's a valid suggestion to update the design to make the spring-loaded alignment bearing adjustable. The cutting plate, which incorporates this spring-loaded bearing, is interchangeable, allowing for different dies or cutting plates to be used as needed. The cutting plate itself functions as a die integrated into my manual hand press. Depending on the project, I use various custom-made dies and cutting plates designed specifically for the belts I produce. One of my concerns with die-based punches that rely on a clicker press is the limitation imposed by the fixed design of the die. If the die components are welded together, you're restricted to that specific design. I needed a tool that allowed flexibility, where I could easily swap out cutting and punching tools in my manual hand press, which led to the development of my design. My goal was to create a small, lightweight, and portable press/punch that is user-friendly and versatile enough to make belts on demand, whether I'm in a hotel room, at a trade show, or visiting a client. Clicker presses are often too heavy, bulky, and restrictive from a design standpoint. I wanted the freedom to create and adapt designs as needed, which my model allows. While I own a range of clicker presses, from manual to hydraulic, and even high-end machines capable of punching belts at high speeds, none offer the on-demand design flexibility that my portable press does.

-

Thank you for the above. If you google any one of my products and I have many, you will find out that I do not sell them or market them anywhere. My intentions are to network with like minded people in the leather industry. What is your opinion on my leather punch? Do you find it an asset or a valuable tool for belt makers?

-

I am showcasing / showing off what I make. Maybe someone else may need help or advice that I can help with. Every post made does not have to be for sale?!?