-

Posts

57 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by BianVariani

-

-

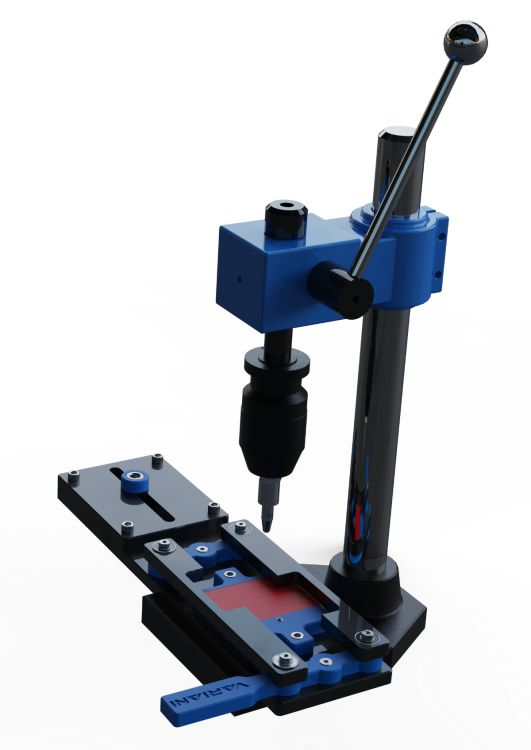

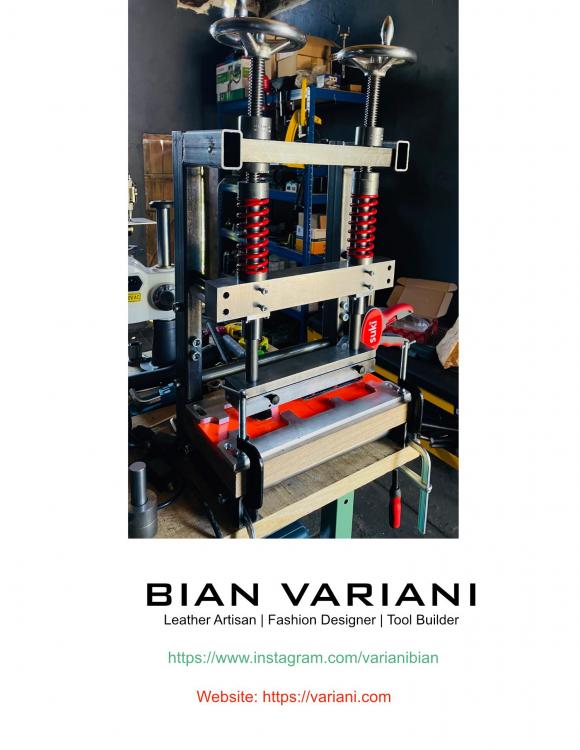

Yes, I do indeed craft high-quality tools for both the fashion and leather industries. As a fashion designer and leather artisan, I produce high-end apparel and accessories under my own brand. My background in mechanical engineering enables me to design and manufacture on demand my own precision leather related tools from concept to final product. Throughout my journey as a leather belt and buckle designer, I've encountered and overcome numerous challenges, refining my craft along the way. The leather belt press/punch/cutter tools I create are specifically designed to streamline the tool setup process, ensuring precise alignment in presses, punches, and cutters, and minimizing unnecessary tool changes. While I have not yet commercialized these tools, I am proud to share my knowledge and expertise with the public. I welcome collaboration and constructive criticism to further enhance my workflow as a leather belt artisan. Having invested in top-tier industry tools from Landis to Omac, my objective was to create a precision tool that is portable, lightweight, and user-friendly—a goal that I have successfully achieved.

-

Advertising??? Where?? How? I do not sell the Punch or Press? I am showcasing what I build and make. These are my private and personal tools that I use in the belt making process. But I do appreciate the incentive to advertise. Thanks for the data above!

-

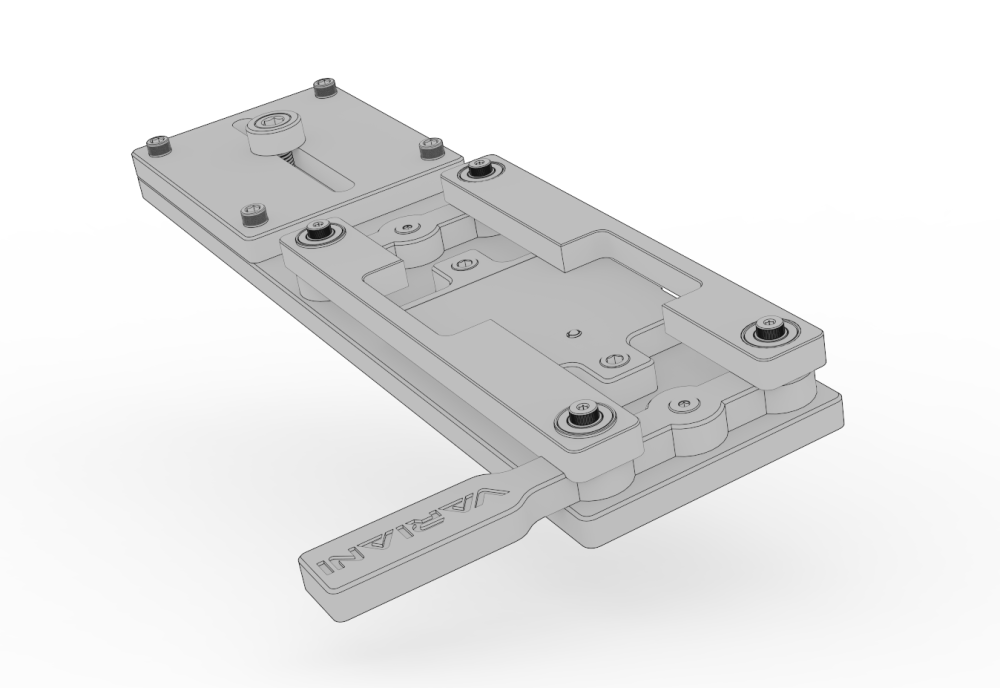

The cutting plate integrates both a cutting surface and a tool guide. This innovative design features a built-in, spring-loaded bearing that consistently aligns the belt hole distance from the hole punch, guaranteeing perfect spacing with every use.

-

Achieve flawless hole punching, precise cutting of belt tops, and seamless cuts of oblongs and billet ends. Our system ensures rapid tool changes with unmatched precision, eliminating any concerns about alignment issues.

-

I have developed self-centering tool holders designed to enhance tool positioning and efficiency. These tool holders feature a mechanism that allows the dowel-pin to rotate 360 degrees once secured in the drill chuck, ensuring precise alignment. Additionally, the tool itself can be rotated within the holder to any angle, offering full adjustability in both horizontal or vertical positions (pending on design). Once your tools are aligned to the desired position, subsequent tool changes are as simple as a drag-and-drop operation, significantly streamlining the workflow.

-

Here is a quick video I just made. My volume on y phone is not working the best so I apologize. VIDEO: https://variani.com/videos/belt-punch-and-cutter-machine.mp4

-

Here is a NEW leather belt press punch design I have been working on. I engineer tools for the fashion and leather industry as a hobby on my CNC machine.

-

Here is Leather Belt Hanger/Holder that I made on my CNC. I customize all of my tools and parts for leather belts.

-

3 piece belt buckle. As a skilled fashion designer and mechanical engineer, I create luxury leather belts that combine elegance with exceptional durability.

-

- 2 replies

-

- leather belt tools

- leather belt punch

-

(and 1 more)

Tagged with:

-

-

- belt machinery

- machinery

-

(and 5 more)

Tagged with:

-

I made my first one about 25 years ago. I'm sure that after my posts are public you will see other similar prototypes and ideas of the design above and now with sizable and changeable inserts. It's okay I got a patent on the above 25 years okay. Thanks for the tip Bruce, I will contact my lawyer and see if we need to crack down on more people steeling my ideas. All over the internet I see fake people selling my brand/products.

-

No one on the planet has a leather strap cutter that has changeable and sizable depth inserts. This is an original concept. Are you saying it is similar because it has a ruler and a guide? That's like saying the first electric Tesla car is similar to the gas ford car from 1920.

-

This is what I use for a portable leather belt strap cutter. I made a bunch of custom sizing inserts in addition to the design. https://variani.com https://www.instagram.com/varianibian

-

That depends on the type of stitching you do. For my belt above in RED I used 5 times the length of the entire belt.

- 11 replies

-

-

Ahh yes, I was editing the above in real time. Need time to update. And YES I'm known for grammar errors!!! I copy and pasted the fields as I was building the spot to input data. No big-deal. No I have not made any videos as of yet but it is on my to-do-list.

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

This is one of my 1st belt press/punch that I made for leather belt straps. This is the Hole-Punch for the machine above!

- 8 replies

-

- belt press

- belt punch

-

(and 8 more)

Tagged with:

-

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

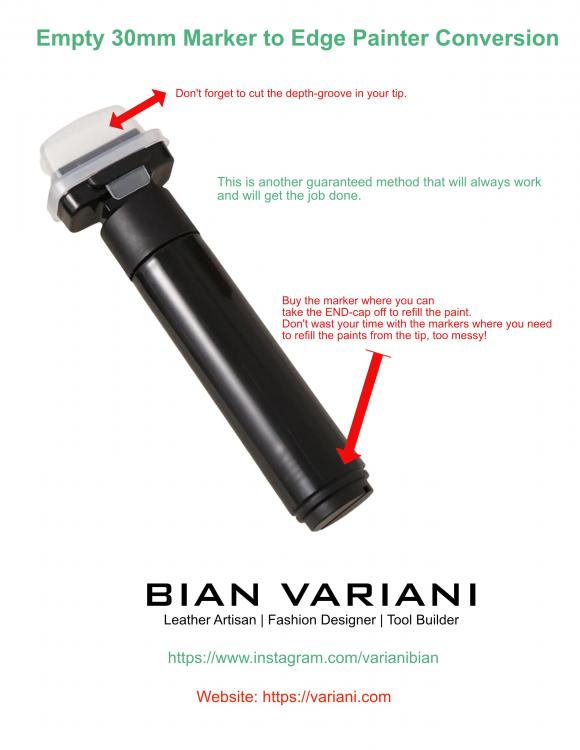

I use different markers for different colours. No cleanup needed, just put the cap back on and put it in a ziplock bag.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

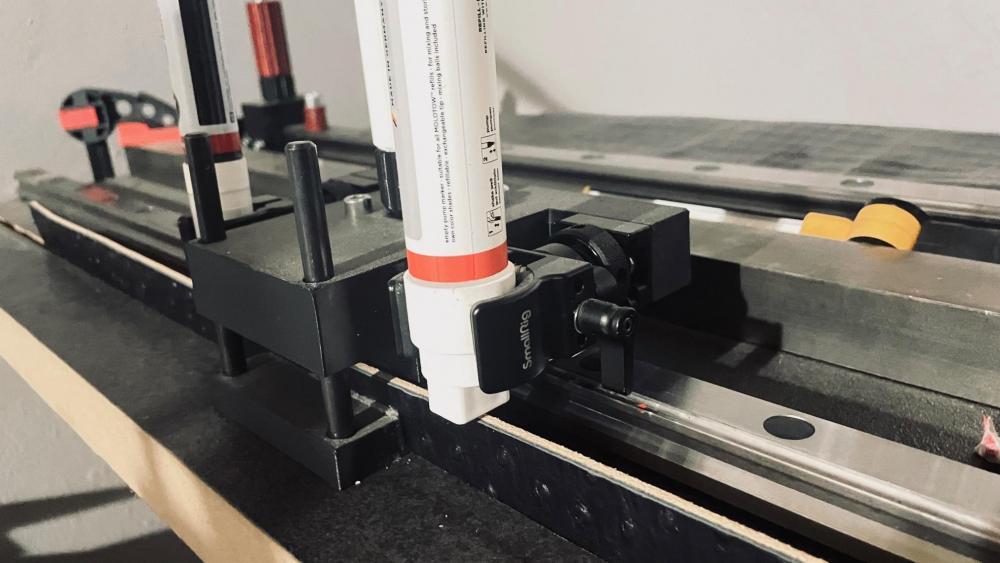

I have the air pressure end capped off with a bolt (not needed). You just can use the trigger and pump the paint to the felt.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

This will always work, but I need perfect pressure and flawless paint strokes so I built the concept with the linear guide.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)

-

The problem I faced with my "Paint Gun Edge Painter Conversion" innovation is that it's too big and clumsy when your belt is sitting in 6mm groove and you need to get above it. The gun would hit the table BUT if you are free styling it and holding your product, then no problems. But I have better methods that work as well. Look at my post with the Spray Gun. All you need to modify is the tip. I customized everything in black.

- 12 replies

-

- edge paint

- belt tools

- (and 10 more)