Search the Community

Showing results for tags 'oiling'.

-

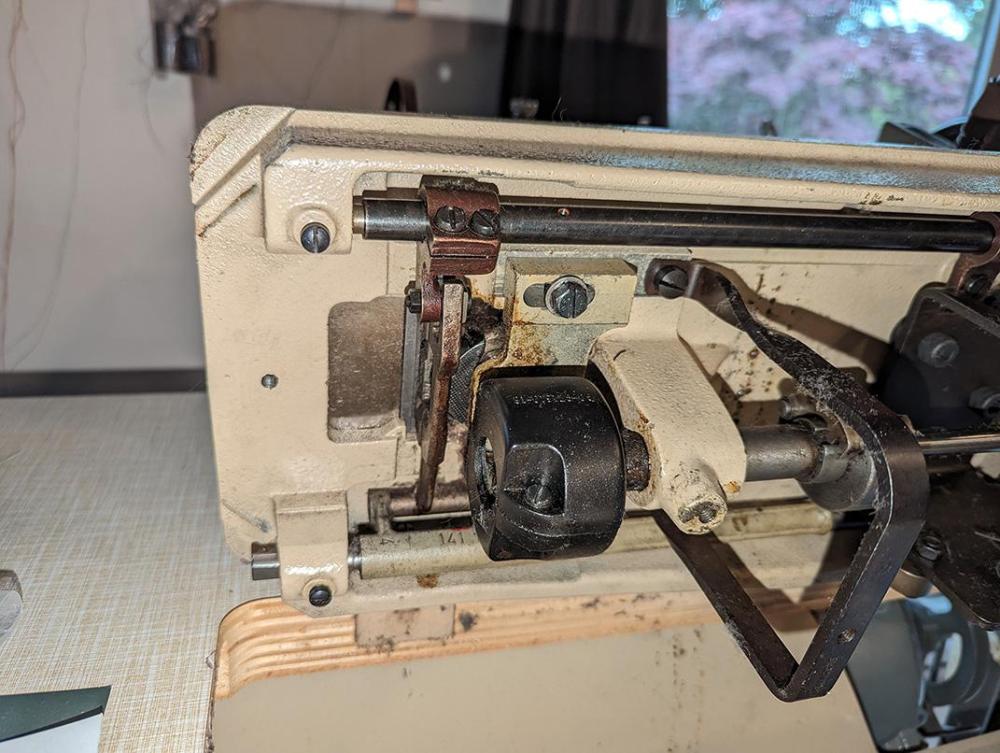

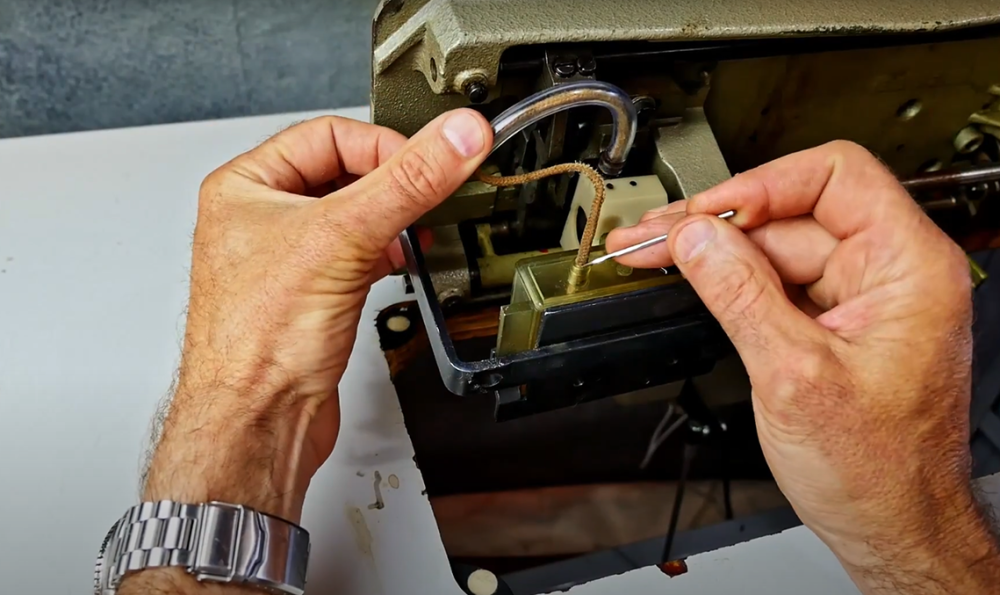

Hi everyone! I've recently acquired an older model Pfaff 1245 and I have a parts/maintenance question that I haven't seen discussed anywhere else yet. A bit of context, this machine was on it's way to the dump and I rescued it - it was abandoned in the alterations department of a clothing store that had gone bankrupt and I was able to take it when the space was being cleared out. As far as I can tell it was being used up until the store closed about two years ago. There were other machines in there which were missing parts or needed fixing but they were labelled pretty clearly so that makes me think this machine is in good shape. The balance wheel turns very smoothly, outside of some oiling and greasing I think it should be ready to use except for one issue: It seems to be missing the oil reservoir that I can see in a youtube video walking through the cleaning of this machine (I'll also attach a screenshot). I also have a pdf manual I've downloaded which isn't very clear, it shows the same oil reservoir (which is supposed to be for hook lubrication, I believe) but also mentions you can oil the hook via a hole in the bobbin area. I'll attach a photo of the underside of my machine as well. It looks very similar to the one in the video, just no oil reservoir and slightly different plastic coverings for some gears. So I suppose my question is - do I need to find an oil reservoir for this machine? It seems like an obvious yes, but there's also evidence that it was being used without that part, and a manual that suggests an alternate way to oil the hook system. Is it possible the reservoir is an optional part to make oiling easier? Seems weird that they would make a machine that way but I've only used domestic machines up until now so I wouldn't know. Or maybe there's a sub-model of this machine that doesn't have the oil reservoir, and mine is meant to be oiled manually? I'm a little confused, would appreciate any insights. Thanks in advance, this forum has already answered a ton of my questions just by reading older posts, I appreciate the expertise!

- 4 replies

-

- maintenance

- pfaff 1245

-

(and 1 more)

Tagged with:

-

I'll be starting to make sandals in a week. The front strap will be an inch and a half wide where it crosses over the big toe's knuckle and one inch wide over the little toe's knuckle. These are the bony protrusions over the ball of the foot and the little ball of the foot. The strap slots will be curved to be parallel with the edge of the sandal. I want to treat the leather with something to make it conform to the shape of these knuckles. I'll be using 8 ounce veg tan for men and 6 ounce for women, an Italian luxury veg tan for the ladies. I had heard I could tell my customers to brush saddle soap and water into the straps before wearing them, and I wonder if that's a good idea and if there's something better? I'll be stitching along the edges, about 1/8" in, to help resist stretching, but it would be great if the central portion of the strap between the stitch lines could bulge a bit to accommodate the tops of those balls. Generally I would like to know what I can do to make the top sole and straps soft and supple, and to prevent cracking teen years later. The top will be shoulder veg tan, 10 ounce. I have another, different, question. If I use 10 ounce shoulder for the bottom sole, glue and stitch the three layers (28 ounces total, equal to 7/16"), and then glue an 1/8" thick layer of gum rubber to that, do you think the sandal would protect the foot from walking on gravel? Or should I use veg tan bend (grain roughed off for two coats of glue)? Does anyone on here make custom sandals? Thanks in advance. My Cobra 26 arrives a week from tomorrow, and I'll finish the six drawers of my work bench maybe tomorrow. After that I'll unbox all my tools into the drawers and onto their fronts, and then start making some sandals. Patrick PS The front strap can be adjusted because the narrow end passes through a channel in the midsole and becomes one of the two other straps that are adjustable by a Conway buckle. I can't figure out how to get this picture appear.

- 21 replies

-

- conditioning

- softening

-

(and 1 more)

Tagged with:

-

Hi! I'm totally new to this machine- I usually sew for a sheepskin tannery on the isle of Skye in Scotland using a one thread overlocker, and at home using domestic machines. My workplace is shut indefinitely due to bleedin covid19, but they've given me loan of a Seiko Stw 8b to see if I can make use of it if and when I go back. I've looked at several grainy manuals online for it, and I think I've neeeaarrly got it going... Its been sitting untouched in an office for ages so I've oiled it, changed the needle- I'm worried I've made a mistake somewhere threading it, and also worried the timing might be out maybe- if it was one of my machines at home I would change the needle and rethread.. any advice would be amazing! I've attached pictures of the wonky stitching and my probably wonky threading. Cheers!

-

Alright here's a question that came to me in the grocery store of all places! As best I've heard olive oil is the best option for conditioning/oiling leather particularly saddles yet, we all know supply and demand has made olive oil definitely not the cheapest oil to choose from. So my question here is what about cotton seed oil? I go to Texas Tech University in Lubbock which is surrounded by fields of cotton, so since cotton seed oil benefits my area I'd love for this to work. It is supposed to be growing to reach more markets but what if this could be a newfound market?

-

Hi folks, I've started using a couple of machines that I've had for a while and was wondering what type of oil and grease you would use for it. My fabric industrial machines came with a few litres of clear machine oil (no label) which I use for them but I'm not sure if they could be used for these machines. I have a Pfaff 335-17B (Cylinder arm for Light-Medium weight material) and a generic 801 Skive machine (bottom feed, no brand name). The 801 Skive has a grease catchment in the top left corner and I don't think every oiling port is visible or I haven't noticed them, the manual that came with it was in Chinese and I downloaded an English version but it wasn't much help (diagrams were too small). With the Pfaff 335-17B I've found the oiling ports and painted a red ring around them. The other question I had would be when I've oiled each port do I run the machine with some scrap leather to clean off the excess oil or do I just wipe it off? Cheers, Jim

-

Hi, I have been practicing with the swivel knife and stamps for a few weeks now. My first projects were going to be checkbook covers but decided they would be a little too advanced for me at this time and the stick barrettes are needed more anyways. The barrettes will be about 2-1/2" to 3", by about 5-1/5" long. They will be dyed black. I will use a dowel rod for the sicks, I will dye those black too. I bought 4oz of Feibings black pro oil dye and from what I understand, this doesn't bleed as bad as the others. Do you think 4oz will be enough to do both? I bought a piece of 6-7oz 8.5"X11" veg tan from Springfield Leather. This should be enough to make both barrettes, but not leaving much scrap for testing I bought a set of hole punches for the stick holes. I was going to burnish the edges and the flesh side. I ordered tools for that. I was thinking that burnishing the flesh side might help make it a little more moisture resistant. I'm concerned about making the barrettes moisture resistant because our hair might be damp when we put it up. Any suggestions on what we can put on the flesh side to protect it from the moisture in our hair? I'm ok with having to reapply something every so often. on the grain side, I will tool them and plan to use Mop n' Glo mixed 50/50 with water to seal them. I read about it on here. I already had it on hand and don't have much money to work with. Does it crackle really bad? The barrettes will be pretty flexible, so I'm concerned about that. I was thinking I should apply the Mop n' Glo, then put the dowel rod through the holes and let it dry in that position. Does that make sence? the barrettes are going to be oval shaped. To cut it out, I plan to use the 28 year old swivel knife I inherited (I have a brand new one for the good stuff) It has been sharpened and I have stropped the h**l out of it. It will cut through tough, roughly 8-10oz cased veg tan in a few passes with a little elbow grease. I know there are other knives I should be using, but I'm very clumsy and feel less likely to cut myself or ruin my project this way. I know I can't do it this way for long, but I will learn the right way in time. Is there anything y'all think I should know? Constructive criticism, suggestions, ideas and insight are very welcome. I'm very sorry I have so many questions. I have no idea what I'm doing, I have no one to learn from. The person a inherited the swivel knife and stamps from got them as a gift and knew nothing about leather work. I know absolutely no one that has worked with veg tan leather. I don't even have access to leather working books through our library because of personal reasons. All I really have is the Internet, just this website really. I have learned a lot here the last two weeks already. Please don't suggest any wool products, I'm allergic. Except the wool daubers should ok since they won't come in contact with my skin. Any responses are greatly appreciated. Thank you for taking the time to read this novel lol.

- 12 replies

-

Ok, so I have a juki ddl 8700 machine that has an oil pan under it. My husband is an auto mechanic and wants to learn more about sewing machine mechanics, but he refers to this method of "self oiling" as "pressure lubed". I also have several other vintage singers for my leather work. The one I primarily use is a 111w155. It does not have reverse, I have trouble adjusting the stitch length, it does weird things with the lighter weight leather, etc; so I'm thinking of getting a new machine. My husband is convinced that the best way to go is a "pressure lubed" machine. Besides juki and singer I have sewed on adler, consew, and brother and would feel comfortable buying any of these. I don't remember any of the machines I've worked on being "pressure lubed" and it has never been an issue, but in searching, I haven't even found any walking foot machines that are "pressure lubed". Does anyone have any info on this? And does anyone have any reason as to why an adler, consew or brother would not be as good an idea as a juki or singer? And is there a place that has a comprehensive list of attachments for singer 111 and their applications? I have a lot more questions, but I'll stop there. Thank you, heather

-

I HAVE TROUBLE GETTING MY WARM NEATSFOOT OIL TO APPLY EVENLY ON WICKETT AND CRAIG SKIRTING LEATHER. IT WILL WICK OUT AFTER A WEEK OR MORE. WHAT AM I DOING WRONG?