Search the Community

Showing results for tags 'pancake'.

-

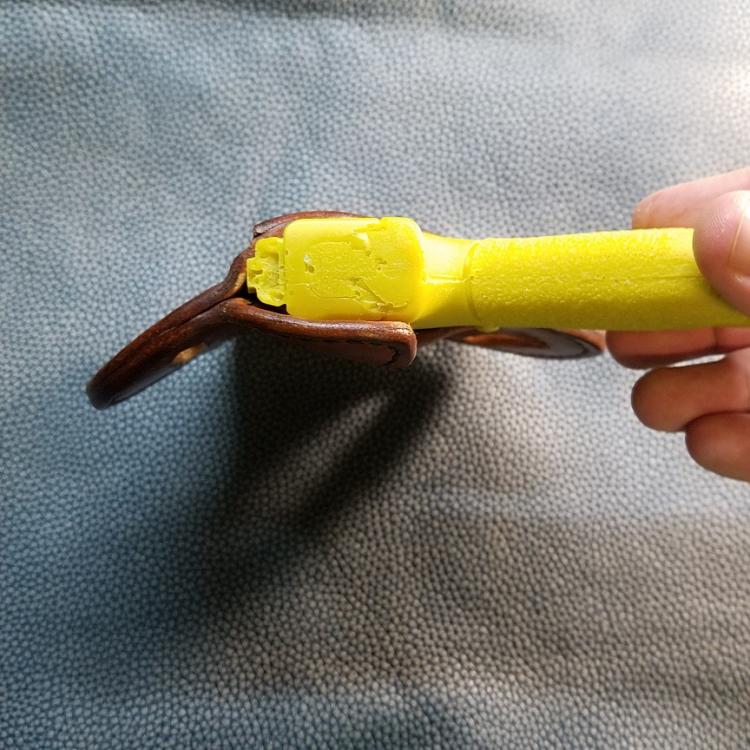

Hey everyone! Been a while since I posted, but in the meantime I got an order for a 1911 pancake holster, first one I’ve made! This was also my first time trying any sort of thumb break, so I made my own stiffener and heat treated it, and it work just like it should. I’d like to hear any feedback y’all have! Cheers, Morgan

-

My very first holster and my very first commissioned piece. I think it turned out good. The customer loved it. I have to pay thanks to JLS holster patterns and instructions, the many hours of youtube videos, and the Tandy Leather holster/knife class to help inspire this work. Tell me what you think.

-

Here's another one off my bench. A holster for a SW Shield 9mm. I tried building it in the curved style. The retention on this one is really nice. I'm happy with that. Threw in a cool Paracord bullet bracelet for kicks, force patina 9mm shells to match haha. It is 2 layers of 4/5 oz stuck together. Critiques welcome. Thanks!

-

Just finished this one up for my uncle. 8 oz. Wicket and Craig, hand stitched, saddle tan and mop n glo finish. I experimented with this one and it came out pretty well. I wanted more of a 80/20 pancake instead of the regular 50/50 to avoid binding. Let me know what you all think. And as with most of my posts, critique is welcomed.

-

Me and a friend both bought springfield armory xdm 9mm with suppressor heigth sights and added streamlight tlr1 weapon lights. Problem . No one makes a holster to accomodate yet. So i made this test pair. I will be making some adjustments to the pattern soon and making another pair but works pretty good so far. Also you can see stitching is not quite completed when i took these.

- 3 replies

-

- springfield

- xdm

- (and 10 more)

-

Me and a friend both bought springfield armory xdm 9mm with suppressor heigth sights and added streamlight tlr1 weapon lights. Problem . No one makes a holster to accomodate yet. So i made this test pair. I will be making some adjustments to the pattern soon and making another pair but works pretty good so far. Also you can see stitching is not quite completed when i took these.

-

- springfield armory

- pancake

- (and 10 more)

-

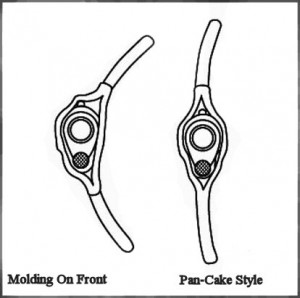

Stumbled across this picture on the web somewhere.. guy claiming that one is thicker than the other and thus his was "better". In under a minute, let me show you why it doesn't matter Here's the picture. Somebody was claiming that the one on the right was somehow "thinner" and thus "more concealable" (and it's debated on a number of gun forums). BUT ... In both 'versions', the gun is the same thickness. And there are two layers of leather, one front and one back. And that's it. The gun thickness plus two layers of leather, is the same either way. While they can be made to RIDE differently, just changing which piece gets the molding will obviously NOT change the thickness of the holster. When worn, there could be a little air space between teh wearer and the holster, especially close to the firearm. But the holster where the gun is will be against the hip (in both cases) and the thickness is the same, so they protrude the same amount. So what's the point? Molding in the front panel, or molding both panels to the middle, SAME thickness.

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power© Privateer Leather, 2016

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power© Privateer Leather, 2016

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power© Privateer Leather, 2016

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power, rear© Privateer Leather, 2016

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power, rear© Privateer Leather, 2016

-

From the album: Various Holsters

Privateer Leather Highwayman for Browning Hi Power, rear© Privateer Leather, 2016

-

Here's a new holster with a lizard inlay (from the Springfield Leather scrap bag). It's Fiebing's mahogany oil dye, Ritza 1.0mm cream thread. I was especially trying to keep clean edges and stitching on this one. Always something to improve! All the best, Tanner @claridge_leather (Instagram)

-

Here is my first revolver holster- a gift for my Dad. He likes to inlay a Montana coin in his woodworking projects, so I thought I'd do the same for his holster. Thanks to everyone here for all the tips I have gleaned over the past months as I've taken up leatherwork. My learning curve has been shortened considerably thanks to all the expertise offered here. What a great community! God bless, Tanner

-

From the album: Holsters

-

From the album: Holsters

-

From the album: Holsters

-

- saddle stitch

- pancake

-

(and 2 more)

Tagged with:

-

A friction pancake sheath for a Leatherman Blast. Made of 2,5 mm veg tan, dyed with vinegaroon and hand stuffed with a mix of tallow, beeswax and extra virgin olive oil. Front piece was moulded on the multitool and it's my first attempt at boning. It has great retention. I tried turning it upside down and shaking it, won't come off even though it's quite heavy (6,9 oz. / 196 g). On the belt. Also, a couple pictures of the process. Had to scrap that one. The bottom was too narrow. Cheers

-

From the album: Various Holsters

"Highwayman" mid-ride pancake for CZ-75 -

From the album: Various Holsters

-

From the album: Various Holsters

-

From the album: Various Holsters

.thumb.jpg.891e1a568fe12892afcab0e6d40cb306.jpg)