Search the Community

Showing results for tags 'pigskin'.

-

Hi everyone, This Is my first post here on the site, but I've used it for awhile now. When it comes to lining leather, whether it's pig skin, lamb skin, etc., how is it that I burnish the edges without the lining mushrooming or crumpling when I go to bevel? I've read that you should cut the lining smaller than the leather piece it'll be attached to... but I've also read that to get a full contact with lining to glue it down to the leather, than cut down to the needed size. So, I'm not too sure. Any advice helps. Thanks

-

I quite like the look of pigskin and would like to buy good quality pigskin in 3-4oz weight an 1-2oz weights ideally from a store in the USA. Smythson used to use this material a lot. It is quite attractive particularly in a golden brown and lighter colors...seems like they don't use it anymore though. Picture from Watch Collecting Lifestyle

- 1 reply

-

- pigskin

- pigskin liner

-

(and 1 more)

Tagged with:

-

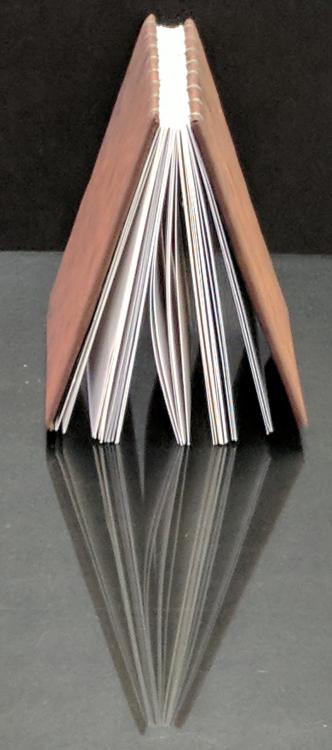

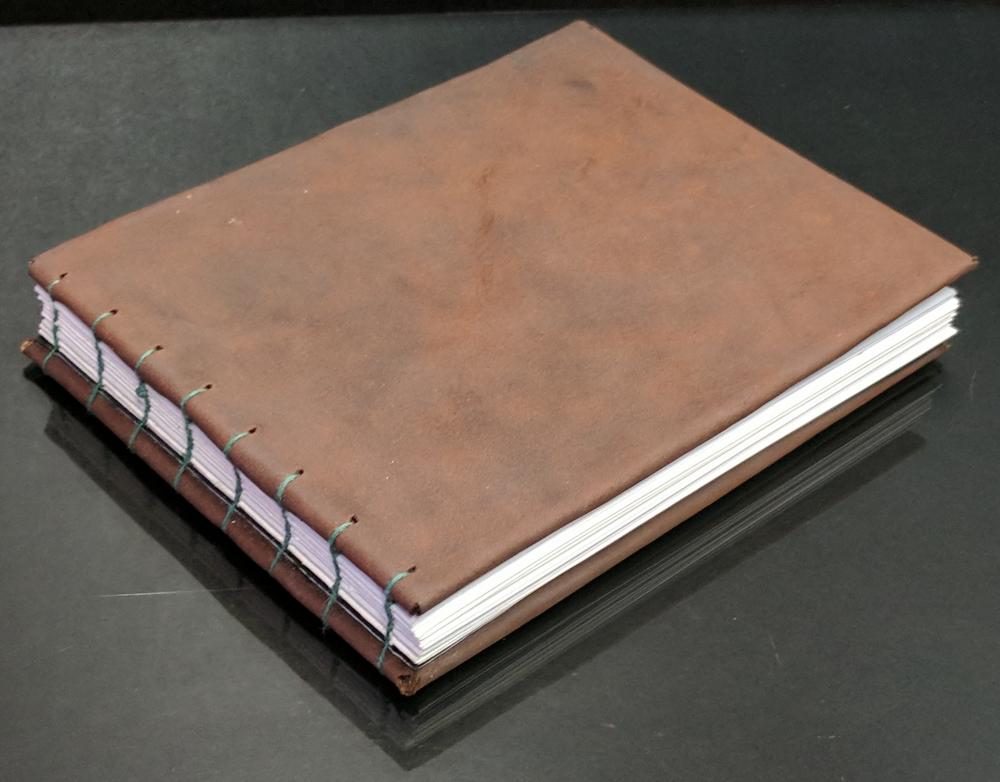

Decided to actually use some leather and made a sketchbook out of rag mat board covered in Horween and pigskin. Made 8 registers out of different colored acid free paper and stitched it all together with green linen thread. I think it looks pretty nice! You can see in the close up of the spine that I had to splice the thread together. At one point it made a knot and snapped.

-

I've just had a delivery of some lovely pigskin suede (suede both sides. It's beautiful and soft, I cant imagine a material that would feel better for lining wallets. My question is that I'm a bit paranoid that the edges of the suede will fray or go fuzzy over time? Will this happen or will the suede hold its shape? Do I need to do something like put glue on the top of the edges or treat them somehow or will it just hold its shape? Also when I burnish the leather edges wil this affect the suede as the burnishing tool may come into contact with it? Thanks for any advice :-)

-

Hello all, i started working with leather last september to make leather masks, at the moment though i've been trying my hand at a number of different projects. Most recently i have decided to take a game out of my board game collection and convert all of it's pieces and board into leather (a good excuse to try my hand at different leathers, some stitching, some dyeing, etc.). For the board i have acquired a piece of pigskin suede which after a number of attempts i have managed to dye to my satisfaction on both sides without having the dye come through the sides. (i'm using fiebings leather dyes for this project) however i rapidly realised that if i was to use the dyed pigskin suede for some board gaming i want to give it some protection to the elements (mainly waterproofing), especially since the dyes are prone to run and bleed even with small amounts of water. As such i have been testing my hand at a number of different products; -the eco-flo sheenes have proven (expectedly, as they are water based) inappropriate at any sort of waterproofing (and caused a darkening of the leather. - resolene seemed to do the trick, although as it is essentially a plastic coating on the pigskin it has lead to a bit of darkening as well as a significant change in texture. The resolene treated leather (i did three coats per side, will look into the effectiveness of a single coat in the coming days) feels a bit "plasticky" to the touch and has acquired a slightly shiny surface coating. - My third test was with a spray on product for suede waterproofing (http://www.amazon.co.uk/gp/product/B0078O9I5O/ref=s9_simh_gw_p309_d1_i1) I chose this as i hoped to achieve some waterproofing without having a loss of texture or appearance. At the moment the spray, when applied lightly (too heavy applications cause dye bleeding) has kept the texture of the leather as well as the original appearance. The water resistance seems superior to untreated leather (water beads on it) but i suspect it will withstand less well when immersed in water with respect to the resolene treated samples. (tests being carried out this week) Has anyone tried to waterproof pigskin suede in such a way that the dyes will not run when in contact with water? What did you guys use and what would you suggest for this situation?

-

Newbie Needs Help With "woodland Distressed Pigskin"

InTheMiddle posted a topic in All About Leather

Hi, Brand new here to the site. I've been working with leather for a very short amount of time. I bought some of this "Woodland distressed pigskin" from Tandy. It works well for what I'm making. Someone has asked me to make an item for them and to somehow imprint their initials in it. I realize that it can't be stamped, but I was hoping someone had an idea of how I could add their initials. I'm a little desperate to find a way to do this, because people love the item, and the leather used to make it. I'm selling stuff to be able to keep up with this hobby that I've come to love! Please let me know if you have ANY ideas. Thanks! -

Caramel Goatskin Big A$$ wallet - inside the billfold

grmnsplx posted a gallery image in Gallery- Our Leatherwork

From the album: Caramel Goatskin Big A$$ wallet

-

Hey guys, I've been making a few passport and card holders and for my last one I decided to line it with some Tandy Premium Mission Grain Pigskin Lining Leather, I glued it to the main piece and then trimmed the excess, I assembled and stitched everything and then burnished the edges, I usually get a smooth and clean edge but this time, with the lining, it looks like it's cracked, as you can see from the pictures I've attached. I'm not that familiar with pigskin, I'm guessing this particular piece is not of the greatest quality and that may be the reason why I can't burnish it very well, I'm from Portugal and before I bought this piece from Tandy I bought a piece from a local shop, it was really cheap but seeing as I had never bought pigskin before, I thought I was getting a deal (I'll attach a couple of photos later), when I got home I took a good look at it and it was kind of flimsy and had a greyish color to it, I also tried dying it just to see the results and it didn't turn up very nice, I wanted to know your opinions and if it's just the quality of the pigskin or if I should be using another technique! Thank you very much, Lourenço

- 10 replies

-

- edge finishing

- pigskin

-

(and 2 more)

Tagged with:

-

Finished my first proper project as a Christmas present for my girlfriend. Lined with pigskin, found all the stitching quite tiring! It's 10 inches wide so just fits an A5 pad, has a 3-piece gusset, and uses Sam Browne studs to close since buckles seem like a hassle (will see how well these work though...). Had some interest in making more but would have to charge ridiculous money for it to be economical Still all good fun. P

-

From the album: Gunslinger Rig with Crossdraw Holster

-

- gunslinger

- holster

-

(and 3 more)

Tagged with:

-

Hi All, I'm about to work with some sand colored (think light tan, beige etc.) pigskin suede splits and I would like to decorate the edges. That being said my first thought was to brand them with a nice pre-made brand design. Of course, I'm finding that locating such an item is extremely challenging and even non-existent -- not to mention out of budget. Because of the color I'd like to burn/brand a nice crisp black into it - design to be determined, but since it's an edge think Celtic, floral or some other nice continuous design. I also would like the design to be at least an inch wide such that I could put two (or more) together and it would work continuously, as if it's one. I've got a soldering/hot stamp tool and would like to know if this is something that I can even accomplish? What other ways can I get a nice black, "stencil-like" design onto the pigskin? Doing the design itself by hand isn't a great option - I've got alot of edges ). I also doubt stamping would work with some color added to it...but maybe I'm wrong there, having never done it before. I also would prefer the end design to be black as I think it would stand out quite nicely. Though at the very minimum it would have to be a darker brown so it would show up. Any ideas from the more experienced folks? Thank you! Lisa

-

Hey everyone- I am brand new to the forum so I apologize if any part of this post doesn't adhere to community guidelines or practices. This is a long post- sorry about that. I wanted to err on the side of clarity. Please see my attached image- it should clarify as well. Here's the deal: I want to make a pair of minimal, soft but sturdy shoes fitted to my own feet for indoor wear while practicing kung fu. They'll be fairly simple, styled somewhat like a ballet soft shoe (pleating near toes- here's an image of what I'm thinking of imitating regarding pleating: ballet shoe) with an insole for cushioning made of a single piece of thick leather (or midsole? I'm not quite clear on the difference between the two but at any rate, my shoe will only have two soles- an inner one touching my foot and an outer one touching the floor) and an upper made out of one solid piece of leather. My basic plan is this: an insole made out of relatively thick and stiff leather will be cut to the shape of my foot (I'm going to call this the insole unless someone corrects me). An upper, which I would like to make out of pigskin (smooth side out), will be something of a u-shape cut out of one piece of leather (sort of like this), with the round part of the u being the toe and the ends fastening on the outside of the heel with a heavy-duty snap. This upper piece will be wrapped around the insole and attached on the bottom first with stitches on the very edge, and then contact cement for reinforcement. I will probably then shave off extra leather with a razor blade to make the shoe feel flatter underfoot- I've seen this done in a ballet shoe video and figure I can replicate it. One end of the u will wrap around the heel, and they will overlap and be fastened with a snap to enable easy removal since I want the upper to cover my whole foot, unlike a ballet shoe which has a short vamp and covers only the toes (see attached drawing). Finally, a full sole made out of either a very short-nap suede, if this is obtainable, or less-ideally, standard smooth-finish leather, will be applied to the entire bottom surface of the shoe, covering all of the pleating etc. I will probably cement this only as my understanding is that contact cement can be softened by heating when it's time for resoling and the sole can then be removed easily and replaced. I want to make an upper that will last forever and can easily be resoled when necessary. Thanks for reading that giant explanation! Here are my questions: 1. What material would be most durable for the sole? I put a piece of ebay suede on another pair of shoes and it's falling apart- fibers coming off, bare spots etc. I know dance shoes have a very short, fine suede (chrome suede?) that looks almost like a chamois and it's much more durable, but I don't know if this is widely available in leather shops. And will I be able to remove the original sole easily by heating it with a hairdryer and pulling it off? Or will that damage the rest of the shoe? 2. Is a single layer of pigskin strong and sturdy enough for the upper of the shoe? Again, I want it to be soft and flexible but not floppy, and I don't want them to stretch out so that the shoes slide around. It seems to come in a maximum of about 2oz. Should I use two layers so that one can act as a lining- or perhaps use a layer of the above chrome suede as a lining if I can find/afford it? Would having two layers rubbing against each other degrade the leather faster/should I sew them together anywhere other than the edges of the piece? I could do some sort of pattern on the top of the foot if sewing the layers together is necessary, but the less work, the better. I do need the shoe to have a certain amount of structure so that it holds shape and doesn't twist on my foot or allow me to slip sideways off the insole. I chose pigskin because it's supposed to be the most durable and breathable and is also pretty inexpensive, but if you think something else would be better please recommend. I'd rather not line with any sort of fabric because again, I want to build these once and build them well and never have to do it again unless I want to. 3. Can anyone recommend a particular type of leather I should use for the insole? Its role is to provide some minimal cushioning for my foot and some structure to make this a shoe rather than a sock, but I don't want anything hard or overly stiff because my goal is to feel the floor- so probably no tooling leather; maybe some thick cowhide? I'm not sure if it should be smooth leather or suede either- I'd like it to last forever and my impression is that the finish on smooth leather is more durable, but I don't want my (sock-covered) foot slipping around inside the shoe. Possibly I should sew a piece of chrome suede to the top surface of it (again, if I can find that stuff). 4. What's the best way to finish edges, like at the top of the shoe near the ankle? Leave them raw? Sew a seam just in from the edge? Fold over and hem like fabric? 5. Should I use artificial sinew? Something else? The shoes will be black in their entirety so of course the thread will have to match. I don't have the time or resources to get heavily into leatherworking, so I'm trying to make the simplest and most optimal shoe without all the heavy duty equipment- I'm not interested in purchasing lasts, a machine, etc. I'm hoping to get by with a new pair of sharp scissors, a few glover's needles and some tough thread. I do have a fairly large awl that might be good for punching through the insole- I don't think the thinner pigskin will require punched holes (correct me if I'm wrong). Here's a quick drawing I made to hopefully clarify what I've said above. If you've made it to the end of this post, thanks for reading and I appreciate your help!