Search the Community

Showing results for tags 'shuttle'.

-

I have a Singer 29-4, circa 1902, S/N K3403-02 While working to restore this machine we have met several challenges but thanks to the web we've been able to fix most of the issues. We have reached one that we can't seem to solve and are desperately hoping that someone here can advise us. The issue is that the needle thread will not capture the bobbin thread. We aren't sure if the shuttle needs to be realigned or is there something that we missed? We haven't been able to find anything definitive that explains how to set the timing for this specific machine. Thank you in advance for ANY help. Sincerely, Nancy & Jeff

- 16 replies

-

- singer 29-4

- 29-4

-

(and 4 more)

Tagged with:

-

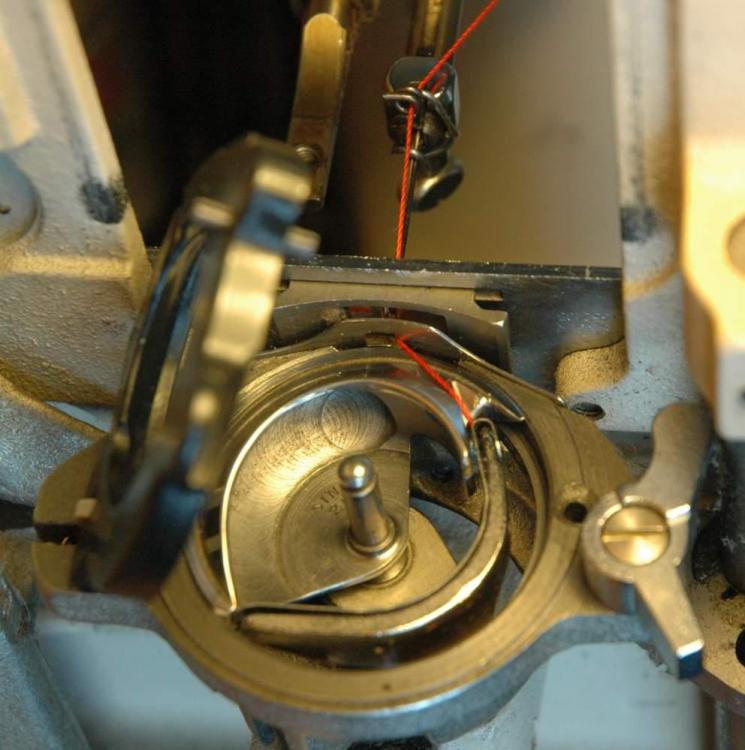

I just like to share a kind of modification I have done on a Singer 237 domestic machine. With this machine I try to make sew with V138 polyester thread, and it fails (of cause). The upper thread gets damaged when I try to sew more than 5 stitches, and then the thread jam or break. So I tried to figure out why. The Singer 237 have got an oscillating shuttle, and it is a zig-zag machine. The Pictures below illustrade the modification: The modification fixed the problem, and now it is able to sew with V138 serafil 20 polyester thread. Of cause I need to increase thread tension of the machine for this to happen as well, and the machine may wear down quick. Before the modification, the shape of this U-turn was rectangular with quite sharp edges. I suppose these original edges will be all right with thinner thread and lower tread tension. However I cannot be sure, if this could be a fabrication error. I have looked at some similar new shuttles for sale on internet, and I think they some of them have got quite sharp edges as well, when I look at Pictures of them: https://www.searspartsdirect.com/product/1i5kk8lux0-0020-385/id-532096007 https://picclick.com/Shuttle-Hook-For-Singer-Butterfly-Flying-Man-Old-153009787971.html#&gid=1&pid=5 https://www.amazon.com/SINGER-Sewing-Machine-Shuttle-Hook/dp/B008MM42UM Has this area of the shuttles of industrial sewing machines for leather the same kind of issues? Perhaps you should expect some Wear on these surfaces as well.

-

Hi, I am new to the forum and have been reading around. Lots of great info here! I have recently inherited a Singer Patcher 29k71 that used to belong to my grand father who used to be a cobbler. He had lots of those, unfortunately, he ended up selling most of the old machines but fortunate for me, this one survived and was passed down to me. I was able to get it completely restored and repaired but i still cant get it to sew properly. I know the problem but i dont know how i can fix it. Problem is that it is timed properly but it constantly gets jammed because the thread ends up under the shuttle carrier. as such, i ordered a replacement shuttle carrier (not an original part) and installed it but i still have the same problem. I was able to get it to sew a few times but it ends up jamming in the end. What i noticed is that the bearing between the shuttle carrier and the driving pinion seems to stick up a little too much. As such the shuttle carrier is too high? Other thing i was thinking is that the hole on the shuttle carrier where you put the set screw is too low and when fastened on the driving pinion and there is too much play. Or the driving pinion is worn down and there is too much play. Either way, before i buy anything else, i could really use some help. Thanks! Andre

-

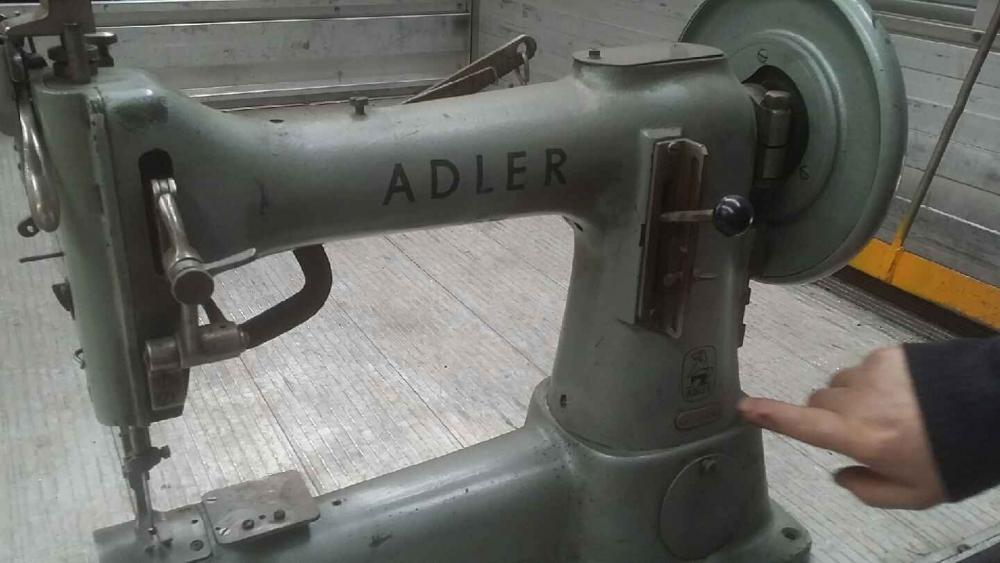

Hi all! New to this forum, and leatherwork too, but it seems to be an amazing wealth of information! I've dove in headfirst and bought some equipment, namely an Adler 30-10. I was aware of the price of spare parts before I bought it, but it didn't seem to be needing too many at the time of purchase (at least to a newbie), and the action felt tight, and turned smoothly. No play in the presser foot and needle went up and down smoothly as well. And seeing as how these never come up for sale in my neck of the woods I figured why not. I'm decently mechanically inclined so I figure I can handle most operations aside from machining new parts! So after a thorough cleaning of the exterior and getting to know the various parts I have a few questions that hopefully you guys have answers to: 1. The only way to transport this thing was on its side. Probably not the greatest idea in hindsight but that's how we did it. About a tablespoon or two of a yellowish oil leaked out of the cover plate on the rear. I'm not aware of a reservoir on this beast, so is it alarming to see this happen in such great quantity? When the time comes to lube it up again, what is the best stuff to use, and how liberally should it be applied? 2. I haven't tried to sew yet, but just inspecting the action of the shuttle/carrier. The carrier itself has play to it. Swings back and forth about 1/8" maybe 3/16". Also the shuttle itself is a Singer replacement but it doesn't exactly fit too tight in the carrier. Should I be concerned with this amount of slack? Is there any way to tighten the carrier up? Timing it will be a whole 'nother issue but is there anything to look for that signals "part replacement"? There isn't any visible grooving of the race/wear on the carrier. I suppose sewing with it is the only way to truly know? 3. Which Singer parts can be used to replace parts on a 30-10? I'm sure I'll have many more questions as I get a few levels deeper into this, but these are the first. Thanks in advance! Stoked to get this thing running its best! Cam

-

- 11 replies

-

How much play (slack should there be in a shuttle on a 900B. Mine is too tight to allow the thread to complete its journey around the shuttle to form a stitch. Any fixes out there? Thanks. Ken

-

I bought a Pfaff 145-6C/D H3SMN. Unfortunately the shuttle doesn't catch the upper thread. I guess that the needle System I use is the wrong one. I googled and found that it needs 134-35 needles. Is that right? For me the needles seem to be to long. The machine came with 459R needles which have a too small upper part. 621 which are too thick and 134 needles which seem to be too short. I hope somebody can help me. Thank you in advance.

-

Title says it all. Does anyone have specifics on where the needle should be in relation to the shuttle hook during operation? I can see where it's adjusted, just want to put it in factory specs. Manual doesn't address this specifically. Thanks so much! Bill