Search the Community

Showing results for tags 'tan kote'.

-

Hello. This is going to be a matter of opinion as there are so many options here. So I'm making a bunch of wallets for everyone for Xmas and I'm curious as to what type of finish I should use or rather what you all would use for a wallet. I'll give some background. The leather I'm using is a veg tan Korba buffalo calf from buckleguy. I'm getting the leather pre dyed (black and another color). Likely I'll burnish the edges with tokonole and beeswax. I guess I'm looking for a decent sheen, the more "luxurious" the better I guess (whatever "luxurious" means to you). What do you guys like to use? What oils do you guys like? Neatsfoot? Mink? So my plan is to use an oil like mink or neatsfoot then finish with tan kote unless someone has a better idea. I think that will be the look and feel that I'm going for. If anyone has any ideas that will help or even just some helpful info on what Im planning to use that would be great. Or even if you have a better idea all together. I'm all ears. Thank you for your time

-

Completed my first halter and would appreciate some advice. I'm having difficulty keeping the stitches uniform next to the hardware, especially when overstitching at the start a stitch line. I am using a double presser foot on a Cobra Class 4 machine with the standard plate and feed dog. The straps are 2 -3 thicknesses of 9 oz veg tan. Adding a welt/wedge to ease the transition helps but I still have trouble maintaining consistent stitch lengths near the ends of the straps. Any tips or tricks? Also, Tan Kote is causing a yellow discoloration of the thread (white 277 bonded nylon). I am using Fiebing's leather stain then oiling with olive oil, and applying Tan Kote after stitching. Does the Fiebing's pro dye eliminate bleeding of pigment? I like the satin finish of Tan Kote but it acts like a solvent and lifts pigment out of the leather. Any ideas?

- 16 replies

-

- halters

- machine sewing issue

-

(and 2 more)

Tagged with:

-

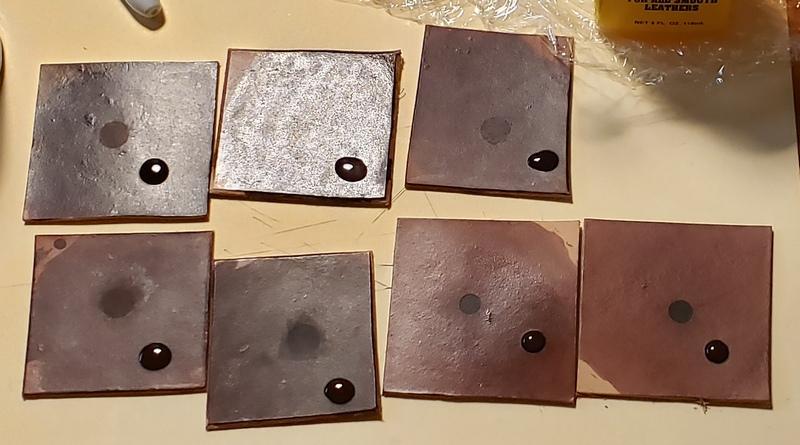

Yesterday, I tested seven different finishes. These were applied over Fiebing’s Pro Mahogany. I was looking for: color change, level of gloss, flesh burnishing and waterproofing qualities. This report is not super organized and may contain errors but I think it conveys the basic results of my tests. I do not wish to spend more time to perfect it because it was a casual test anyway. I put two drops of water on each sample. After one minute, I wiped off one drop of water and let the other sit until it was completely absorbed (over an hour or two). I wanted to know the short term and long term water resistance of these products. When the samples were completely dry, I buffed them in attempt to “repair” them as much as possible, without re-treating them. Buffing did slightly improve their appearance. The damage actually came in the form of cratering. It appeared that the solution had evaporated completely off of the sample. The edge was easy to see and feel. The crater was approximately 1/20 of a millimeter deep. Resolene won the water test. It was completely waterproof. I had a thick coat on there. The color change was quite dramatic but Tan Kote was even more so. Tan Kote was second best. The one minute test showed damage only if the light was reflected off of it in just the right angle. The long term test was a little bit easier to detect but not too bad. Tan Kote resulted in the deepest color change. Shocking, actually. Very dark brown. Satin Shene was a surprising third. The short test did show a very slight discoloration and some loss in gloss. You could tell there was some damage but it was minimal. Color change was very significant. Gum Tragacanth and Tokonole were tied. More damage on both areas than Satin Shene. Sno Seal and Shoe Polish were by far the worst. I must qualify this by saying that I did not warm the leather, nor use multiple coats. I smeared on one coat, rubbed it in and buffed it off. The water damage on these looked like they had burned with a cigarette or like acid had eaten into them. Satin Shene, Tokonole and Gum Tragacanth were the easiest to work with and they all resulted in a very similar semi-gloss finish. Resolene and Tan Kote were sticky and impossible to apply smoothly with a dauber. An air brush would be a much better method of application for these two products. BTW, I did not thin them for this test. I know that is protocol but I am lazy. Both have superior water resistance to the other products tested. Tan Kote can be applied with a dauber and then quickly spread with a finger to smooth it out. This actually resulted in a nice smooth finish that was second in gloss to Resolene, and significantly glossier than the others. If for some odd reason, I could only have one product for flesh burnishing and top coat, Satin Shene, Tokonole and Gum Tragacanth would all work but I would go with Satin Shene, because it had slightly better short term water resistance and it was the best of all the products for burnishing the flesh side. I do not consider this testing to be definitive in any way as it was not scientific and I may get different results if done on different leather on a different day. nick Top row: Tan Kote, Resolene, Tokonole Bottom row: Gum Tragacanth, Satin Shene, Neutral Shoe Polish, Sno Seal

-

Hello I'm wondering if anyone has successfully used Acrylic Resolene on top of Tan Kote. The reason I'm asking is that, after I apply a 50/50(resolene water) coat on top of my tooled and dyed test project (dyed using fiebings spirit dyes), and then apply fiebings antique paste, allow to dry thoroughly, buff, and add a sealing layer of 50/50 resolene, it lifts quite a bit of the antique. I've done some research and have found that to be common, and many suggest using neatlac and tan kote combinations etc. But I'm a creature of habit and acrylic resolene has treated me well over the years with spirit dyes, I know how it ages, it's limits etc, and I'm hesitant to change my top finish, thus I'm wondering if anyone has used tan kote to seal the antique(recommended in many topics regarding antiquing here) in combination with resolene. Of course I will be experimenting, but it can be hard to know if something works well down the road, like the finish lifting or cracking, it may look good now and for a few months but I worry about such a combination failing Cheers! -Cheyenne

-

Hi, everyone! I recently purchased a couple of 4 Oz bottles of Resolene and Leather Balm with Atom Wax to add to my extensive portfolio of finishing options... that only include Tan Kote, besides the message mentioned earlier. My question is: can these products be used together, in different stages on the finishing of one piece of leather? or are they incompatible with each other? I will be dyeing my leather with Fiebing's Pro Oil Dye Dark brown, in case that makes a difference. I remember reading somewhere here that Resolene can be used as a resist before dyeing. if that's the case, what are the benefits of resisting vs not resisting? With just common sense as my ally, the term "resist" tells me that it's intended to affect the degree to which the rest of the products applied afterwards are absorbed into the leather. I know that mileage may vary depending on the type of leather used, the conditions under which the products are applied, etc., but it would be nice to know some of the experiences of other members since the combinations for trial and error are just a step away from endless. Thanks, Everyone!! Efraín.

- 4 replies

-

- resolene

- leather balm with atom wax

-

(and 1 more)

Tagged with:

-

Currently making a belt. When it came time for coloring, I [reluctantly] went with ecoflo stain because I have some from my original tandy kit and want to use the stuff up. Going on I was disappointed, because it was streaking something awful despite my best efforts. I thought, "perhaps it'll buff out". So I let dry overnight. Come back to buff, and while some color is coming off, the streaks and splotches are still extremely distinguished. I dont have a mechanical buffer, and my arm is getting tired, so I figure "hey, if the stain comes off with the tan kote, then at least I get to try again for less streaks." But it didn't come off. Well some did, my rag is now a pretty orangey brown (originally white), but it took away only the streaks and splotches. It actually evened out the entire stain job and lightened it a bit (good, for me. I thought it went a bit dark). Not only that: beforehand I had attempted to resist a couple spots of tooling with 2 layers of the kote, and when I had put the stain on was disappointed that the resist didn't work. Come post-stain tan kote, the resist areas lighten more than the rest (not all the way, but enough), and I'm finding myself pleased. So, sometimes tan kote taking some stain away is a good thing.

.jpg.d60258221c476480a6e073a8805645bb.jpg)