All Activity

- Past hour

-

Thank you . I am ok with the spit by the way.

-

Great eye. I messed up a little here. I skived the edges of the yellow middle layers at a very sharp angle, and didn't use enough glue. So, they were splitting a little after stitching. Then I filled that with some extra glue hoping they would stick now, but they didn't. Next time, I will pay more attention to the skiving angle. I am struggling to sharpen my French style 12mm skiver. Once I figure it out, I guess I will practice some more.

-

Singer 211 U166A walking foot problem

NowhereMan01 replied to NowhereMan01's topic in Leather Sewing Machines

I've been trying to adjust the distance between the hook and the needle, and in spite of at least 25 attempts, I have not been able to get it to sew yet. Either the hook is too far away, and does not catch the thread, or the thread immediately breaks, and I get a mess of thread wrapped around the outside of the bobbin case. Any suggestions would be appreciated! -

Kitchen Scale for Measuring Thread Tension

friquant replied to friquant's topic in Leather Sewing Machines

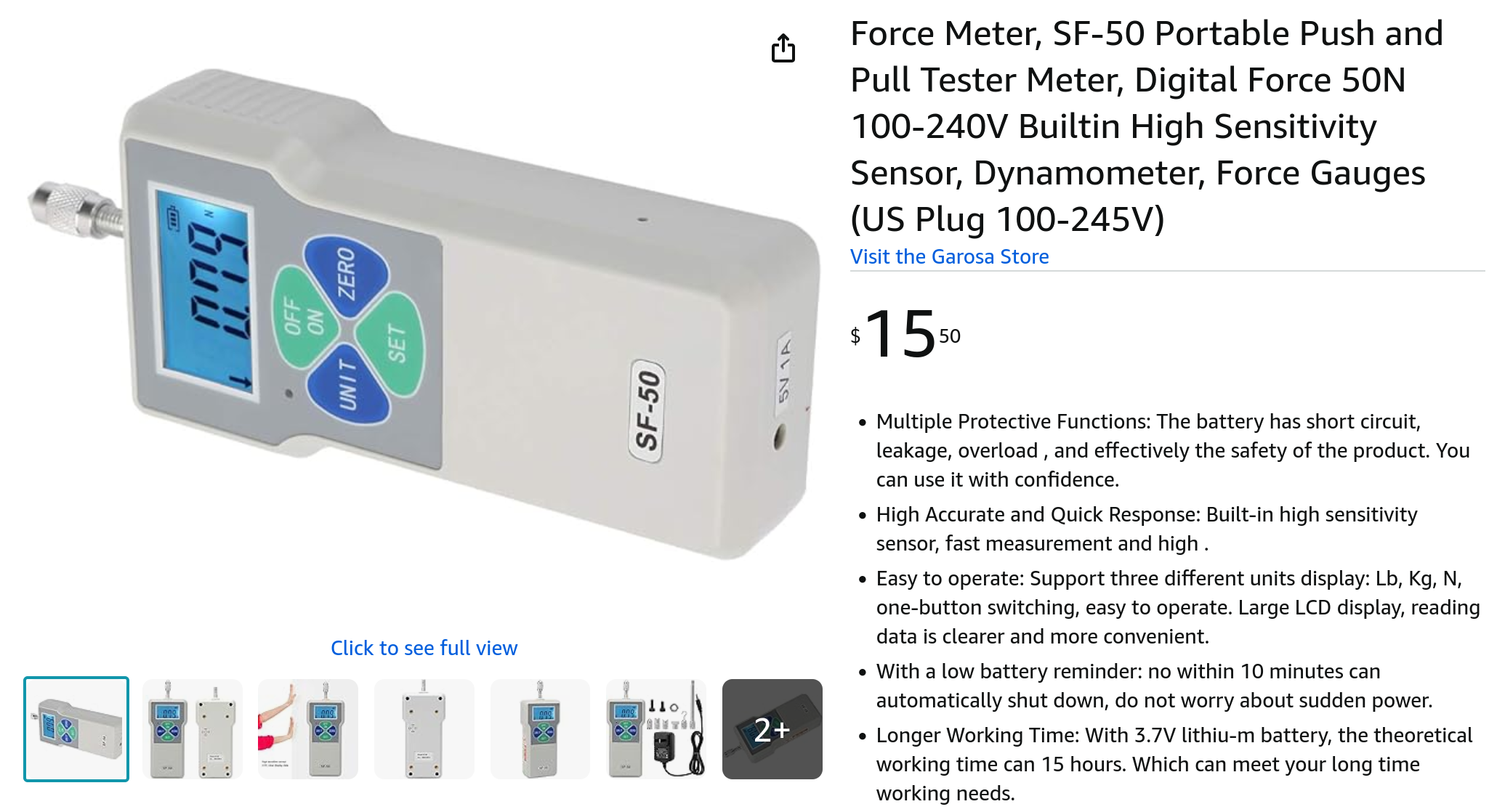

I like the adapted kitchen scale from my original post, but I found myself wanting to be able to measure both bobbin tension and top tension, and the kitchen scale maxed out at 500g. A couple days ago this digital force meter arrived, and I'm using that now to measure thread tension. It has a broader range (50g minimum, 10kg maximum) so I can measure both bobbin tension and top tension with the same tool. It cost $16 from amazon: https://www.amazon.com/dp/B0CYCHKJ75 The 50 gram minimum load is unfortunate. It registers 0 grams until you pull/push hard enough on it to get above 50g. But most of the time I'm running more than 50g in the bobbin anyway. And way more than 50g in the top thread. For reference, with TEX 135 in my Jianglong 341, the bobbin tension can be adjusted from 25g (screw 1.2 or more turns out) up to 370g (screw all the way in.) With the same thread the top thread tension (measured coming out of the thread check spring) can be adjusted from 6g up to 2700g. Notable "features": - defaults to Newtons every time you power up, but you can change to kg or lb - rechargeable! - Startup is slow (5 seconds to power on) - Very fast updates between readings compared to other kitchen scales and fish scales I've used - Buzzer is loud but can be de-soldered from circuit board for peas and quiet - goes all the way up to 10 kg (even though advertised only to 5kg) - It comes with some end attachments and a nut, so I clamp the thread between them which is easier than tying a knot Here is a photo of the insides. The load cell looks quite dramatic. It even comes with a "do not disassemble" sticker which I wish I had kept for nostalgia. - Today

-

Yes, the everyone is an expert mentality is particularly annoying to me with regards to science and medicine. Google/AI turns up random facts (and outright lies) without any context and these are amplified in the echo chamber of social media. Think I'll stick to leathercraft at this stage of my life.

-

Thank you, @BlackDragon. Got some positive comments about the bridle as well, so all is good. Had to look up the quote. I'm stuck in the 70s-90s with my musical selections, but I have an abiding interest in pop culture/Americana.

-

Very impressive work. What a great thing to have in your shop!

-

I'll suggest calling Toledo Industrial at 866-362-7397. I needed some peculiar bed hinges for a machine out of production since 1948. They were in stock for $2.50 each. $9.00 got me 2 hinges and the 4 screws.

-

Hello, I have a Singer 96k12 industrial sewing machine. Stitch lenght numerator is not working. As I read from the 96K12 pdf, stitch length numerator is defined as "thumb screw" "D",and reverse lever is defined as "E". as can be seen from the photo. I demount thumb screw part but I couldnt assemble again.😢(I have spring, lock pin and numerator disc) Reverse Lever E is connected with fork type metal at the inner side (neck )of machine My question is; What will be the key points for this assembling? Is there any correct position of "D" and "E"while assembling.(D at max or min) Or any other important thing like this. Thanks

-

What is the total thickness (including folds) of all the material you need to stitch for the collar? You can measure the width of the needle right above the scarf to see what size it is. I use calipers to measure. If you want to improve your sewing game with your Activa 230, I suggest getting some size 100 and size 110 needles, and buy some TEX 70 thread. Here are the needles I bought, which includes both 100 and 110 sizes: https://www.amazon.com/dp/B09V136BDJ And here is the thread I commonly buy: https://www.amazon.com/dp/B06Y5V3W25 The TEX 70 we use in both industrial and domestic sewing machines. Larger thread we use only with the industrials.

-

Yes Jonas I used evapor Rust Extra strength but I'm having trouble remembering where some of the things go

-

My budget is under 800 so the collar is using webbing (about .6inches thick, fabric and minky not sure if of the exact thickness. I would like to use a thicker thread but my machine now can’t take a thicker thread also the photo is not my work but a picture of what I’m going for. I’m using a BERNINA activa 230. Not sure what needle but I went to a local quilting store and she gave me a better needle to try to go through everything.

-

Repair of leather edge on Louis Vuitton bag

PrePro replied to Mulesaw's topic in Satchels, Luggage and Briefcases

wow no rush at all - just whenever - this is great thank you for being so helpful! -

Repair of leather edge on Louis Vuitton bag

Mulesaw replied to Mulesaw's topic in Satchels, Luggage and Briefcases

Hi PrePro I can't remember the thread colour/brand, but I'll sign off the ship tomorrow and go home, so if you can wait one more day, I can tell you the brand/colour. Regarding the pig skin, it was something that came from my dads collection after he dies, so I have no idea whatsoever of the brand. I would look for a colour in the whiskey/cognac range (depending on what the store will call it) Like this: https://www.laederiet.dk/shop/81-foerskind/4030-svineskind/?variantId=20968 I used some double sided tape to hold the edge in place during sewing. It is not messy like contact glue can be, and it is plenty strong to hold the pieces in place while you sew, and if you mess up a bit when placing it in the first attempt, it can be removed without making a mark etc. Brgds Jonas (who will be back with more info tomorrow) -

Dummy gun

wizard of tragacanth replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Hey Dwight, Thanks for the hot tip on those ebay dummy guns. They are actually affordable... and you can choose your favorite color. They don't have very many models available at this time (not even a standard P365) but this is one of the very few S&W BG 2.0 that I have seen anywhere. -

What machine make and model are you currently using? What size needle and thread?

-

Nice find and great job so far. What method did you use to remove the rust? Brgds Jonas

-

Dummy gun

KillDevilBill replied to KillDevilBill's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thank you! I wasn't sure where to put this. -

You can look up bag stiffeners in google. Here are a couple links that may help. https://www.rmleathersupply.com/collections/lining?utm_source=chatgpt.com https://springfieldleather.com/products/bontex-bag-stiffener?_pos=1&_psq=bag+sti&_ss=e&_v=1.0

- 4 replies

-

- bookbinding

- what is it

-

(and 1 more)

Tagged with:

-

Now you have a reference! And can see if parts from one fit the other 🪚

-

Hey @AlZilla thanks for your input! Ideally I'd be able to buy something instead of bookbinder board. I'd hate to have to glue something to the back of it since it adds cost and effort, even though I do really like the canvas idea. I'll look into how to do cross-posting of this in the Suppliers category, see if someone wants to sell me the right product.... Thanks!

- 4 replies

-

- bookbinding

- what is it

-

(and 1 more)

Tagged with:

-

Leatherman sheath

Stetson912 replied to Stetson912's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks! -

II have been searching for the replacement parts, and the more I search the results were coming back to the Consew 227r the parts and they look identical, but I do not know if they are interchangeable. I wanna change the feed bar and the lifter fork, Because the litter Fork runs in grooves inside of the feed bar which is what it's called. . on a total coincidence I picked up a Consew 227r the parts a nice and tight not, lose at all I totally agree with you traying to buy them now.

-

I moved your post to Stamping

.thumb.jpg.6e903dd66163ad5672f00f144058c571.jpg)