All Activity

- Past hour

-

Basically a manual clicker press, I saw one on youtube and thought that looked useful. Amazon (Aus) had what was an older version with needle bearings on the shaft end for what was a good price ($178) and by signing up to their app (which I won't use again as I prefer using my computer) I got another $20 0ff. $158 delivered was too good to pass up. It arrived today, well packed, and I forgot how heavy 50lbs is!!! This thing is built like a tank! As a bonus it is the later model with big bearings on the shaft ends. So, the base and pressure plate are made from 5/8"/16mm plate steel, the main support bar is 1 1/4"/30mm bar and the upright bolts are 3/4"/17mm rod. The end bearings are 1 3/4"/45mm diameter and the pressure plate 10.2" x 4.7"/260 x 120mm. I'm glad I didn't get a bigger one because of the added weight. It has a travel of 1/2"/12mm and claimed downward pressure of between 1 - 1 1/2 ton, depending on which article you read. A quick trial of the only clicker die I have handy (lent my other ones to a mate) and it went through the leather like butter! Should be good for imprinting things too. Me happy.

-

My thoughts and experience. 1 - You can’t change the overall blade angle much with stropping compounds even if you use black emery. If You can do that, you have my respect for perserverence. 2. You can however round over a blade edge very easily using mild compound on a strop and either a) - not keeping a constant angle or rolling that angle b) keeping the angle too high or c) using a soft strop 3. Use a mild compound on a firm surface like card stock, file folder, or hard roll horsebutt for stropping a swivel knife. And don’t do it a ton. A few strokes to clean but much more than will violate point #2 above. I like purple compound but green or white is OK. Whatever you’ve got that isn’t black or red. Round and cutting knives can use a “softer” strop like vegan leather because a little convexing of the edge can make a “Moran edge” that is durable. On the other hand Swivel knives I feel need a flat edge all the way out for easier and cleaner cutting. That means a harder strop and less aggressive compound. I’ve had a bunch of swivel knife blades through here in all tiers of quality and use. I probably have 75 blades right now. When I sharpen one I set the blade up in a jig and mark the facets with fluid. . I can guarantee that more than 95% of them will not scratch the marking fluid off the very edge intially because the edges have been rounded from in inconsistent angle on an abrasive maybe but mostly due to over stropping. I go back up the grits to something coarser to flatten the facets and bring back the angle and then run through my grits to 5000. Then I strop with the jig at 1 to 1.5 degrees higher with purple compound to take off the burr edge. It’s literally almost just a touch on each side for the bur. By hand, there are a few jigs I like and the Big Red you mentioned is sure one of them. I think hitting a blade on 2000 if needed and then 5000 wet/dry with a jig and a light strop as above to maintain is better to maintain than stropping the crap out of them like has been recommended by a lot of people the last 50 years. My thoughts for what it’s worth.

- Today

-

New offering. I’ve had requests for a true bandolier style rig so about a year ago I started working on one. After much field testing, here it is! Fully adjustable, non slip shoulder strap, and works perfectly with my existing chest rig holsters (as a conversion). Please ignore the model-he’s rough around the edges, but works cheap…

-

Yes, when my eyesight was good enough. When I was a member we had access to all military small arms (semi and full auto), ammo and training. Back then the DCRA competitions were limited to military ( commonwealth countries only), Canadian police forces and DCRA members. The DCRA was limited to military, ex military or reservists and police. All firearms and ammo had to be military compliant and no scopes. I am surprised you managed to get across the border without some of those pretty silver brackets. kgg

- Yesterday

-

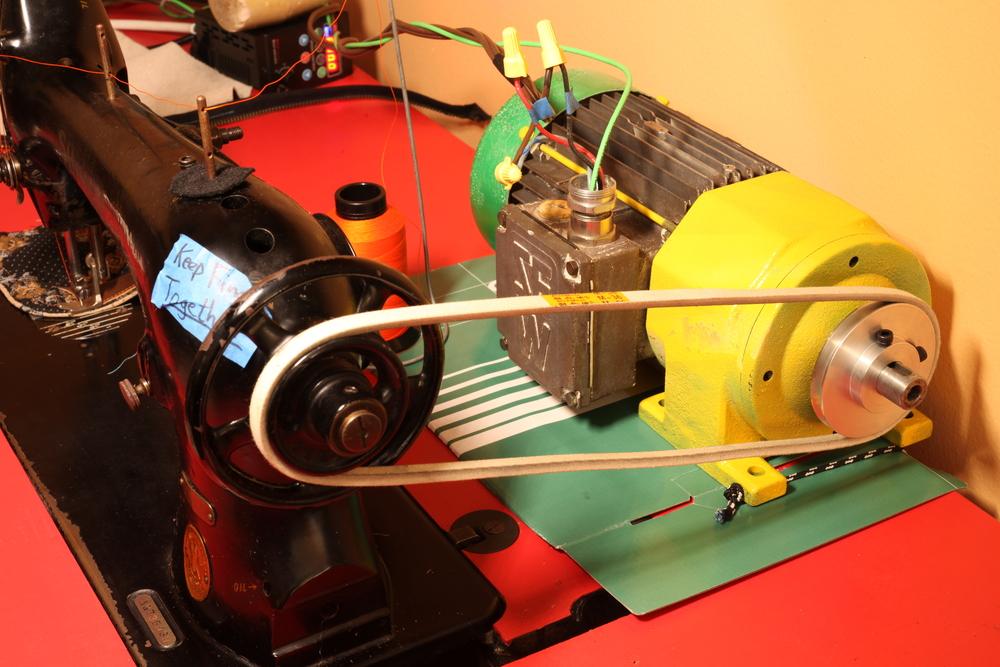

The motor howls---I suspect it's a bearing inside the gearbox that has a pitted race. I have not been able to get the front cover off the gearbox. Next time I'll tap it with a sledgehammer to knock it loose. The VFD has a noisy fan too, but the motor howl is the bigger problem.

-

Impressive, lots of torque there. I doubt if overheating is likely to be a problem for home/hobby use. It sounded pretty noisy, or is that just an overly sensitive mic?

-

You'd have to do a lot of stropping with a coarse abrasive to significantly change the blade geometry! Eventually though it would need touching up on an oilstone.

-

I suspect our firearm regulations make Canada's look good! I shoot primarily Single Action so reload pistol cartridges (.38sp and .44-40), the Dillon is for the .38 as progressive presses tend to destroy the thin-walled .44-40, I use a Lee turret press for those. I modified the Dillon to use a 4-tube Lee case feeder and a 4-tube boolit feeder, plus a vibrator on the powder hopper as I was getting uneven powder loading with the DuPont powder I got hold of. Bob, I usually have the door open unless it's raining but you're right, it's probably the last remaining bit of free space, I'll have to give it some thought, I should be able to use it for something. PVC tubes for leather rolls might work......

-

That looks great, I wouldn't have known it was a home-made job if you hadn't said so.

-

Is it possible to change the geometry of a swivel knife blade just by stropping it? My knife came with a fantastic blade and I would hate to alter it to an undesirable angle. I probably don’t strop it as often as I should and when I do it’s only stropped two or three times on each side. Still, if need be I could get something like the Big Red by Chuck Smith to correct the angle. Thanks

-

Thanks! I've been enjoying it 🤠 None so far. My duty cycle is quite low in general as I'm typically spending much more time thinking about sewing and planning the design than I am actually stitching. The only instances where I can see a good use for going ultra slow is at the start of a seam (when I'm scrambling to make sure I've got the thread held down while also driving one-handed), and at a corner or end of a seam when I might slow down to make sure I bury the needle when I let off the gas. The middle sections, especially of straight seams, warrant higher speed else one gets bored. I conjecture that a few seconds of ultra-low speed at the beginning and end of each seam, even if they do cause extra heat (I'm unclear on this point) won't cause enough extra heat in those few seconds to cause any trouble---the heat will be absorbed by the mass. As far as what could potentially overheat, and how to measure & test that, I'm open to suggestions. VFD This VFD has a temperature sensor for itself, and you can specify what temperature is too hot and it will disable at that temperature. Motor This motor does not have a temperature sensor that I know of. I could imagine nesting a thermistor between the coils of the stator and running the thermistor wires out through the electrical box along with the power wires. I have not adjusted the volts-per-hertz settings at all yet, but that's worthy of testing out. I wish this VFD had a setting for overall reducing the amount of current (torque) going to the motor, but I haven't found a setting for that yet.

-

My First VFD w 3-phase AC Gearmotor

Cumberland Highpower replied to friquant's topic in Leather Sewing Machines

That's pretty awesome. Im left wondering a bit. With a VFD you probably shouldn't operate your motor under 400rpm (it might overheat). With the 4:1 reduction that would put you down to 100rpm. Of course the reducer might allow you to cheat the overheating part by allowing less load at low rpms so maybe you could push it lower under load? Have you had any trouble with overheating? -

Got it cleaned and painted Here it is set up temporarily with the Singer 31-15 And a video of how it operates using the TIG pedal's contact switch and potentiometer to activate the VFD when you step on it. vfd-intro.mp4 Would like to find a reliable, inexpensive source for these gearmotors so we can set up a recipe or parts list for anyone who wants to go this route.

-

I wouldn't use the word addiction KGG, maybe more "appreciation" LOL Do you shoot in competition? Back in 2000 I joined the DCRA for one season out of curiosity and went up to Connaught Range to take part as a Civilian in the CFSAC. Surprisingly as luck would have it, I was disqualified during squadding. (I was 5 min late). Later on I found out it was a blessing of sorts...For the match I brought a pair of Colt AR match rifles, about 3k rds of ammo and a duffel bag of 20rd magazines along for the trip. The Rifles were legal of course, as I had applied for an "ATT" but the ammo circumstance and the bag of high cap mags were apparently not....Considering many of the participants were either RCMP or OPP I probably would have been in cuffs before the day was out! So I decided to go sight seeing around Ottawa for a day before heading back. Another stroke of luck! it's a real bummer what they did to you guys up there under Trudeau when it comes to firearms. It was bad enough before.

-

I like it. Wish I had a small shop in South OZ I could call my winter destination!! When I was still living at home years ago we had a shed set up kind of like that. I started making M1907 Match slings 30 years ago (!!!) and had it split 1/2 leather stuff, 1/2 reloading. Never reloaded one pistol cartridge in my life (unless you can somehow justify 444 is one). Loaded TONS of rifle rounds though. Always looked at Dillons but shot so few handguns it was easier to buy for those.

-

@Pdm25150 Good to hear that you beat the heart attack, and nice job on those zippers. Cutting into something expensive is always a daunting task. Did you also install those "don't chafe the upper part of the heel flaps"? They look really good too. brgds Jonas

-

SuiceCharley joined the community

-

Is it a swing out door? Do you keep the door closed when you are working in the shop? You could always put a couple of shelves or peg boards on the inside of the door. Or mount some large cardboard tubes vertically on it to store some of your leather.

-

The first image of the Subaru car coaster is right out of the laser. I wipe it with a damp rag, let it dry, then dye it with a light brown Feibing's Pro Dye. Same process for all the images...except different dye colors. It took a minute to dial it in, but works well on Hermann Oak veg tan. I have tried it on the Live Oak tanned leather from Traditions leather out of OKC, but it doesn't laser well for me.

-

Yes,some long bobbins are hard to find BUT we have these bobbins in stock.

-

Harry Smith joined the community

-

I have a spiralbound copy of Bob's book. Practically new, never did end up very good at carving. Sorry not digital though! I am actually on here because I am selling a bunch of my books and stuff. Hands no longer work the way they did, so need to lighten the load a bit. I haven't even put anything up yet, if you guys are interested, let me know Thanks, Only

-

huntermangrey joined the community

-

Hal9k joined the community

-

Thanks for the feedback guys. Yes, it is a small holster, and proportion does make a difference, And yes, some people would actually really like that look. I don't hate it but I think for my next project, I will try 0.8mm or 0.85, with the 5spi irons I tried Ritza one one project in the past and seem to remember that it is essentially a hollow tube that lays very flat and that did not appeal to me. I prefer the twisted cord "rope" look. Dave... beautiful work... My next project is a holster for my Kimber K6s DASA 3", so I can relate to snubbies.

- Last week

-

Ah, you guys are funny. The roof isn't that high, plus the fact that under certain weather conditions I get condensation on parts of the roof so moisture could drip on anything stored there. kgg, it's a modified 650 press, I managed to get one of the last ones here in Oz before the 750 arrived. I had a Lee Loadmaster before that but I got tired of the primer problems it had so swapped to the Dillon, it's a great press. What on earth do you do that requires 3 1050's?

-

pazjulianapaz joined the community

-

Nice old iron. Others have given good advice. My only comment is finding the boat type bobbins can at times be difficult so don't loose / damage the one you have in the machine. What is the going price roughly these days??? kgg

.jpg.647a45e2187d47f71b5de9574b945163.jpg)