All Activity

- Past hour

-

Almost New Omac Leather Belt Machine for SALE, only used for 1 month. Call, Text, WhatsApp: (604) 449-0099

-

I have a Tandy Leather Tipping Machines for sale. 100% New in Original Box! Custom make leather belts! Call, Text, WhatsApp: (604) 449-0099

-

-

Dwight Thanks so much for your detailed suggestions - I really appreciate it! The idea of using wooden dowels as stand-ins for the pens makes perfect sense. Since I don’t have a woodworking space, I’m wondering: where would you recommend having wooden form made? I also watched a pen case tutorial Kgg shared, and I believe that doesn’t require a wooden form. If you were in my position, would you rather choose that route considering the difficulty of sourcing a form? Just to clarify, this is part of what the client asked me to make. He’s not asking for a standalone pen case, but a complex A4 shell cordovan portfolio with : a full-zip opening, one side is to hold 12 fountain pen SECURELY, pockets for cards/misc items on one side, and an A4 notebook slot on the other. Since I’ve never made this type of pen case before — and because it’s in shell — I want to prototype a standalone pen case first before incorporating it into the folio. I’m also thinking of making pen cases with my own design as part of my product lineup , so the prototype will be worth the effort beyond just this commission. Alzilla Thanks! The client told me the brand and model of the pens he uses, but I’ll be sure to ask for the exact measurements to make sure everything fits perfectly. TOXO Thanks for sharing your thoughts - I really appreciate it! I answered your question above, and the brown insert does come off, which could allow for a main base with removable inserts for organizing the pens. I will double check the pen size with the client, and I size the slots with a little extra leeway. billybopp Hello! Kgg Thanks for sharing! I’ve actually watched that video before, and it looks like that method might not require wooden forms? So if I run into trouble making a wooden form, I could try that approach instead. And, just out of curiosity, how much would you guys think is a fair minimum for a project like this if you've been crafting quite some time and have made small accessories to brief cases and using shell quite a bit? Wondering how a build at this scale might be valued by fellow craters. I barely interact with other makers, so this feedback is really refreshing - thanks again!

- Today

-

Bringing a neglected machine back to life (Juki LU-563)

MikeG replied to MikeG's topic in Leather Sewing Machines

It cleaned up very well and runs smoothly. After a thorough clean, I blew air in it to dry it out and was rewarded with what looked like a full bag of sunflower seed hulls. Guess somebody was living inside it! I'm very happy with how it is turning out. Thanks all for the encouragement. -

I have these folded bulls I bought years ago from Tandy I just came across them and there are no pattern with them must of got lost at some point does anyone know where I can get the pattern for these bulls?

-

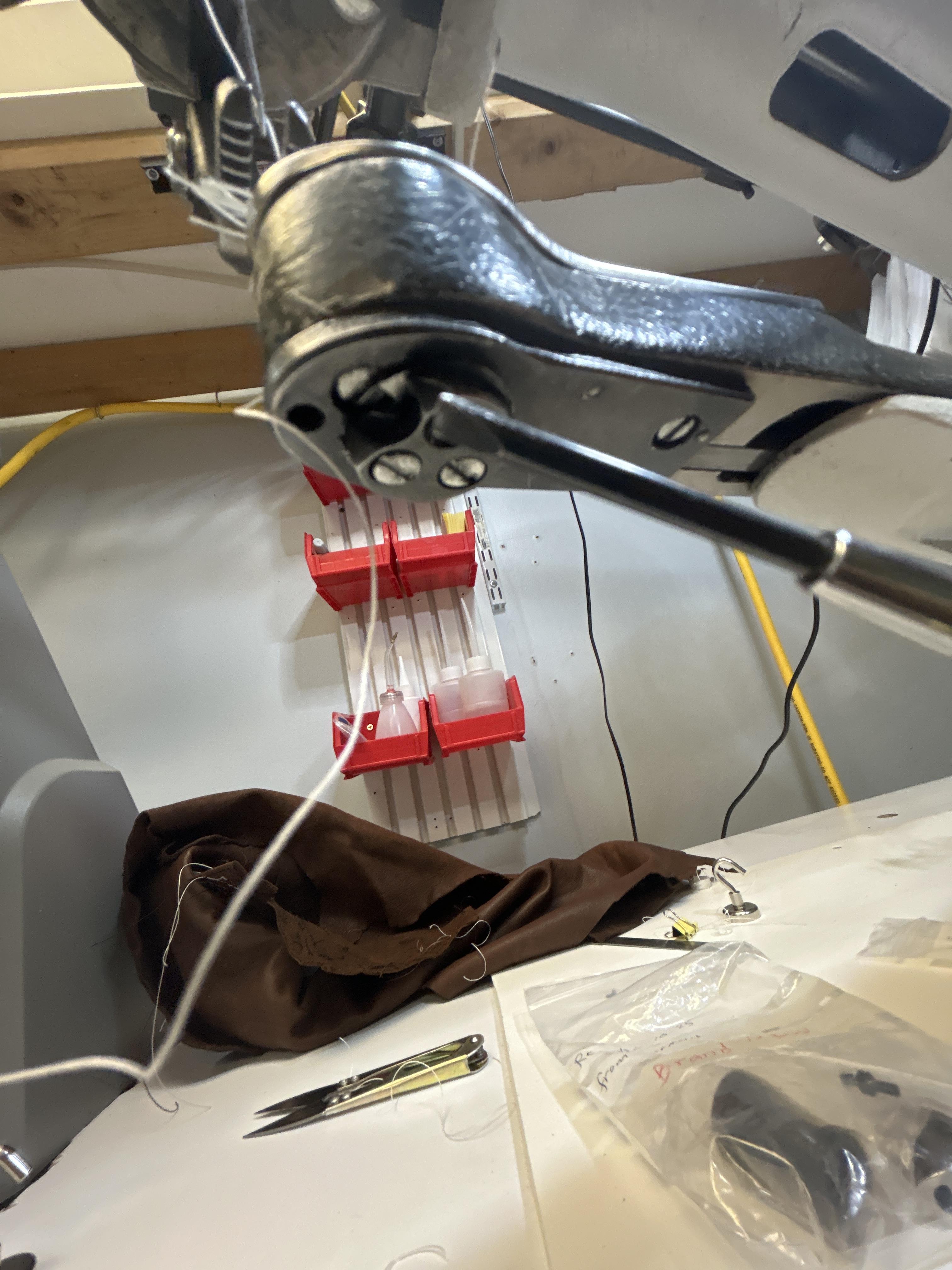

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides. I apologize if I’m confusing you with the descriptions I’m sending and also the photos and videos. I’m 60 years old and not computer savvy. The following is how I have threaded the machine. 78501902954__897B199B-5A3D-4478-933F-9F8AC642717F.MOV

-

This is the other end of that arm that I sent you the video tape off. 78501837289__24339A00-5D8B-4808-8111-8B94FB3A4AFC.MOV

-

One more thing I like to inform you of. There is quite a bit of play at the end of the trip of the arm. 78501818481__899B42F4-DEA4-405E-B3F3-DAE2255951F2.MOV

-

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides. this is where the top thread ends up and the machine just stops completely.

-

By the way, less than a year ago, I replaced the following parts. The machine was working flawlessly, but then the machine would stop completely. After looking around. A noticed the following wedges which I removed and ever since the machine were just not work well even though I put them back. I was told by Landis International these wedges are not part of the original machine. Even though I am the only owner of that machine. But then I remembered having someone work on this machine about five years ago, and the only explanation I can offer is that he must have put these wedges in there.that would be the tip of my screwdriver pointing at the end of the wedge. I’m going to take them out and show them to you.

-

My apologies to you, I was so in a hurry to show you and tell you what was going on. I forget to send that information.

-

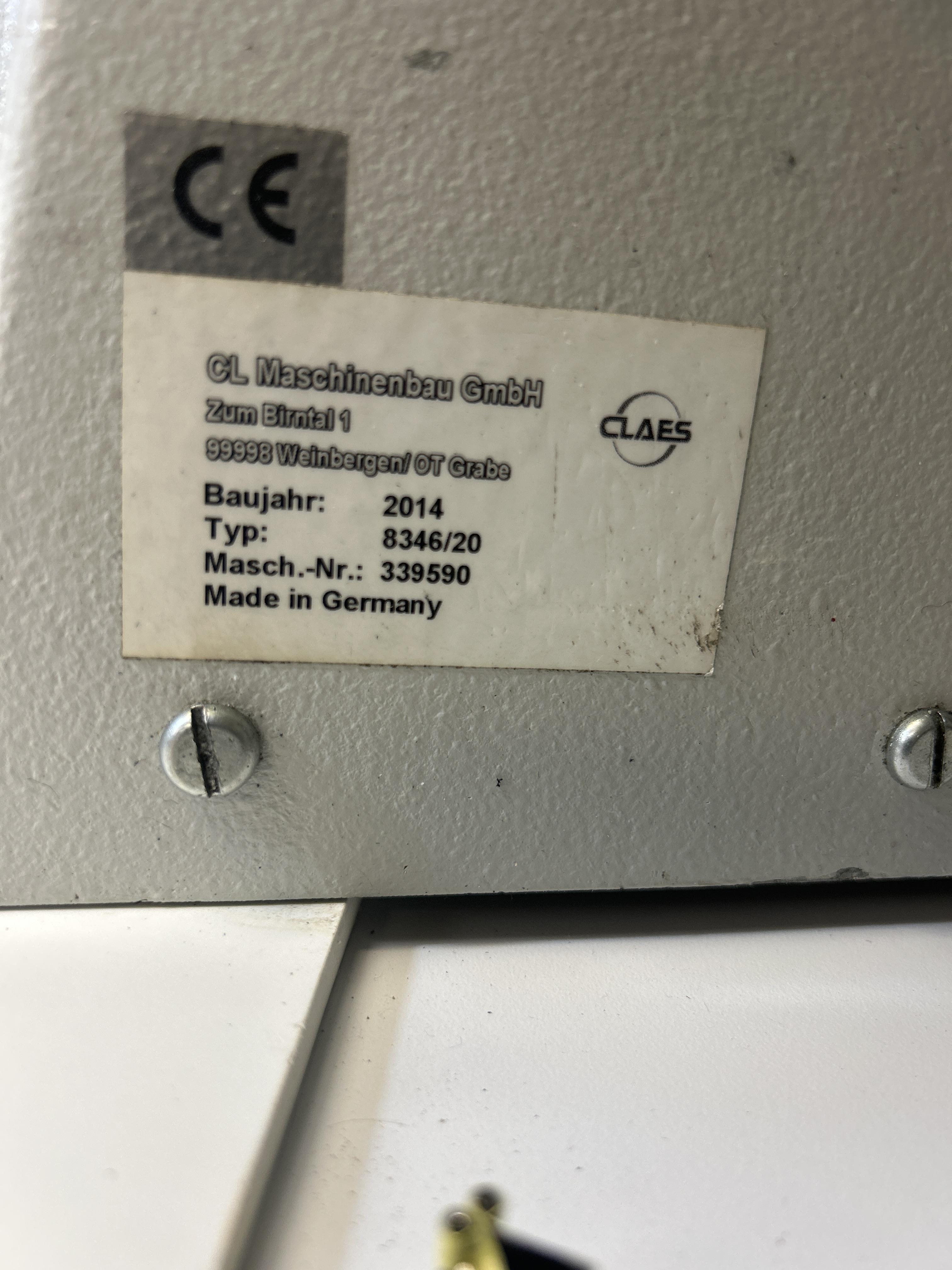

well they are not all the same, thats why I asked for the model - CLAES has a long history and made patcher machine for many decades. Beside the even older "COLIBRI" and "Patent Elastic" machines they had the Model 201, RPX, 200, 8345 and 8346 - I assume you have the latest 8346, right? Just from the picture I would say you have a tension problem but no timing problem. Can you post pictures of how you have threaded the machines? I assume a loss of top tension for what ever reason.

-

I really appreciate your help. So we won’t get confused the first machine we will call machine #1 It’s not working 95% correctly. The second machine we will call machine. # 2 , which I purchased 10 years ago. I’m having timing issues with it. Since all Claes machines are the same, I tried to adjust the timing of machine #2 to the same timing as #1 but no success. please note the second and third photos are the same but from different sides.

-

More thoughts... Re: mineral content of water for wet forming. Distilled water has zero minerals. Tap water varies greatly from source to source. Las Vegas has fairly hard water, 291 ppm as reported by the Water District. Over 300ppm is classified as "very hard". It's well known that we have high Calcium. I think it would be important to know the mineral profile or at least the Hardness of the water used if planning to do comparison tests. Re: leather weight & detail molding. As Thadrick mentioned, a thicker outside layer makes total sense, if carving is planned, If no carving is planned then detail molding would set the priority. Here, I think two layers of equal thickness are called for because the the thicker the leather the more resistant to details. The simple fact that two layers are being used and being fixed with contact cement, contributes greatly to stiffness. As Dwight mentioned - a hot box. I totally agree. Force drying a wet mold with heat and fan, really firms up a build. In the end, every step in our process adds to firming things up: wet molding & force drying, contact cement, dying, sewing, edge treatment and top coat, all help toward this objective. Don't use NFO or any leather conditioner, oil, cream, etc. I tend to believe that waiting overnight between each of these steps, also helps, but I may be completely wrong. Nick

-

The case you have shown is very similar or the same as the ones made by Libertaz Leathers ( libertazleathers.com ) and here is a video of how they are made. kgg

-

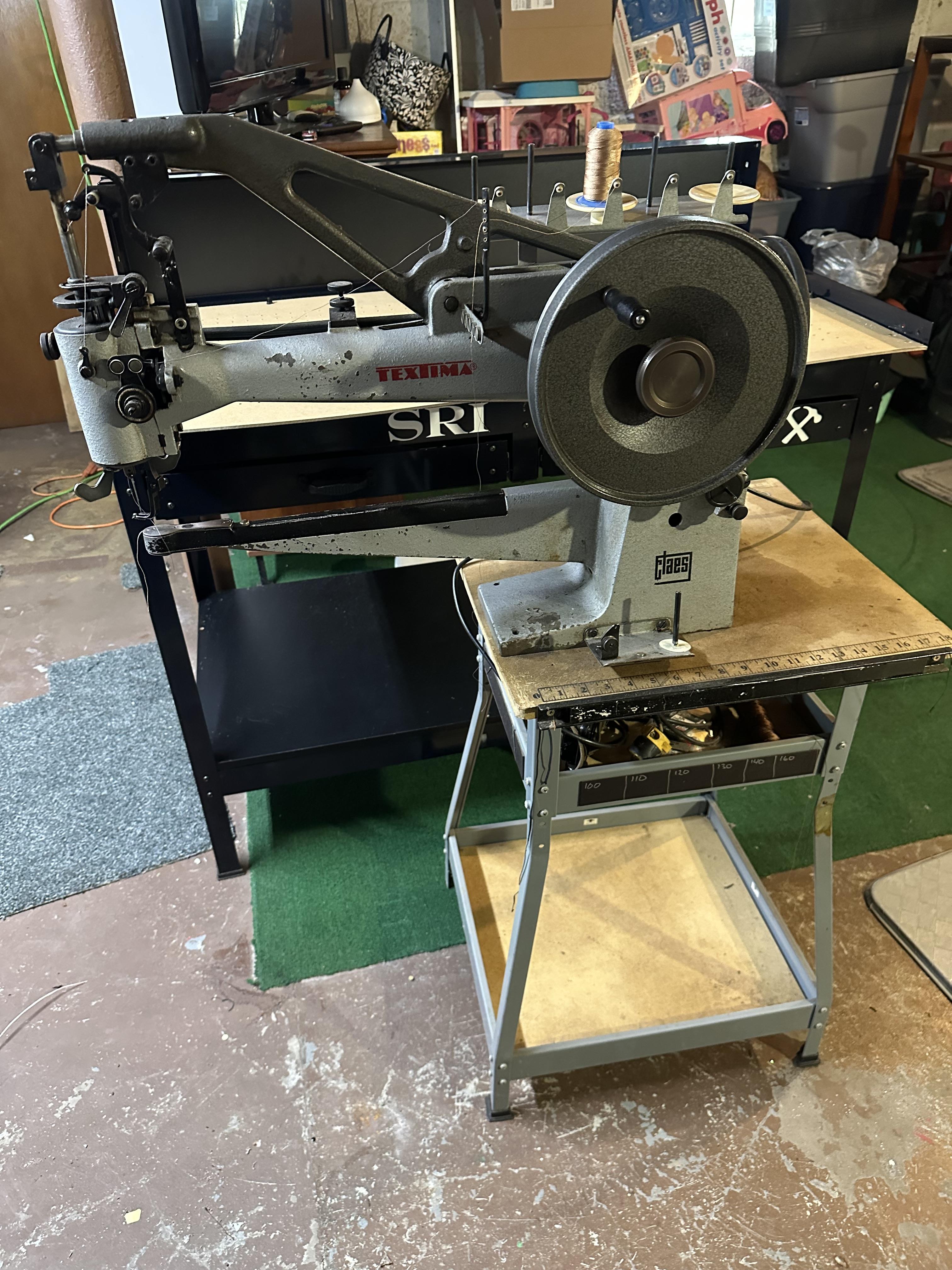

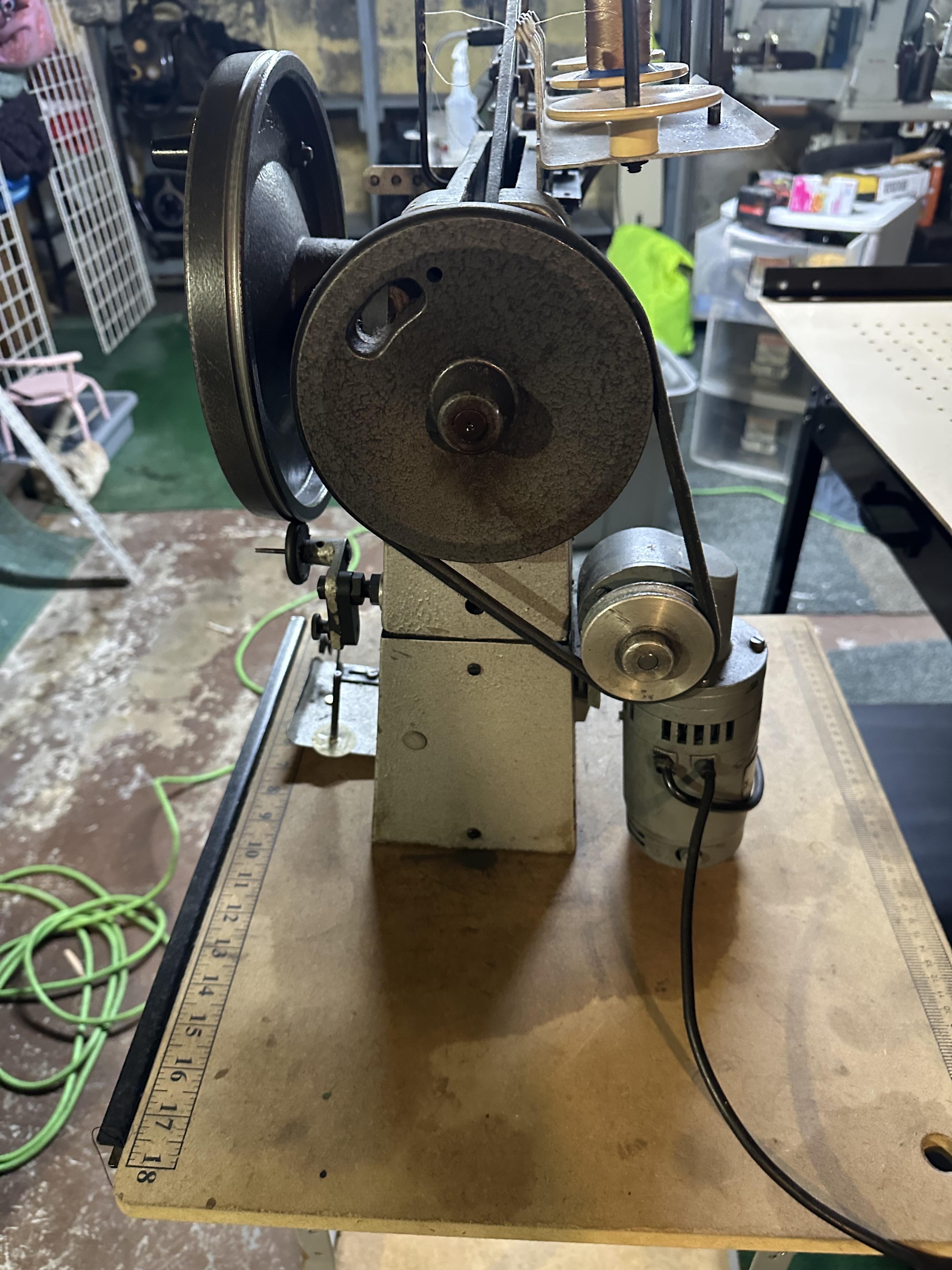

Hello, I have a few machines I’m ready to part with. Cowboy 4500, comes with the whole accessory package with the table and a bunch of feet, lots of extra bobbins and I have thread that’ll go with it in white, black, brown, red etc. also plenty of needles. Has the gear reduction and DC servo motor. Hasn’t been used all that much. New price is about 3400 w/acc package. $1900.00 Consew 206-RB-5. With Servo motor, several feet sets, bobbin, some thread. Thread stand(not pictured). Also not really a ton of usage, table is stained a bit from dye and cement, would probably clean up with some thinner. New price is 1795.00. $950 Last one I’m still debating on letting it go. It’s a Textima patcher which is a rebranded Claes 20. It’s got the good gear reduction motor, I also have 5 extra shuttles which are crazy expensive. Currently mounted to a rather cheap stand but I also have a treadle base for it. New ones are close to 7k. $2300 I also have a Skiver machine I’m going to post in the other section. It’s a dual feed bell sliver w/servo from Toledo Machine, not sure what the new price is on that but I’ll take $600.00 Located in Altoona Pa.

-

Yeah, I saw it after I hit the submit button ... 😱

-

I'm not going to make a joke .... I'm not going to make a joke ... I'm not going to make a joke ...

-

I forgot to add, when making a flat back holster and gluing up the inside and outside. I apply all my glue to both pieces and when I mate the pieces and use wax paper to keep them separated so I am only mating specific areas at a time. I think that would work well when adding a lining. Apply all the glue where needed, add wax paper to the body on each side, press the sight tunnel (bend), and when ready to move, start slipping the wax paper out as you press the leather together. Does that make sense? DAve