All Activity

- Past hour

-

Cobra class 14 splitter

BurntLeatherCo replied to BurntLeatherCo's topic in New and Refurbished to Like New

Understood my apologies, not willing to ship pick up only in Chandler Az. -

They burn all of them here every July 11th Just one example of the many here

-

yes, its nice piece, I would have laced the front panel on as well for continuity . More Viking designs on front panel, back panel and flap. The Vikings did not leave any surface undecorated

-

So, you'll sew the bullet loops on first, then the suede, and then the eyelets?

-

Hi everyone. New to the group here and looking forward to this community. I just finished up my first buttstock cover and need some advise for glueing/stitching a suede backing on my next one. I want to use eyelets on the next one so looking to use the suede to protect. Here’s some pics of the first one and the one in progress

-

Those Vikings had some pretty nice stuff.

- Today

-

This may help: https://leatherworker.net/forum/topic/101339-problem-with-reverse-stitch-tightness-on-singer-industrial/#findComment-685135

-

Yes lots of good options for motors these days. 🤩

-

Fender repair...

Goldshot Ron replied to Brokenolmarine's topic in Saddle Identification, Restoration & Repair

I am going to cover two tasks. 1. Rivet removal tools needed: hammer, sharp center punch, awl, and drill will bit about the size of a number nine rivet. Flatten the burr end of the rivet, punch with center punch to dimple a hole in the burr end of the rivet, drill out the rivet until the burr comes out. Punch out the rest of the rivet with an awl. Be careful not to burn the leather; I use to use a Drimal tool, but it creates too much heat and burns the leather. Stirrup twist: the Blevins pin part can be placed in two different directions. If the pins are facing outward, you cannot twist the ends properly. The pins need to be facing inward, or when the stirrup end is folded, the pins will be toward the fender. In this position, the twist is 180 degrees, and the pins will now face outward (or toward the horse). To set the twists, the stirrup end needs to be wet and the saddle placed on a stand with the stirrups weighted to set the twist. Often, the twisted leather does not need to be wrapped after setting. But, I wrap them most of the time. -

Genius! A larger needle solved the problem, even though I don't understand why it only happened in reverse. I will take the win! Thanks!!!!

-

if it was good enuf for the Vikings its good enuf for me

-

For me, whatever contact cement the hardware store has on the shelf. At the moment, Weldwood, I think? Something like that.

-

The number 19 needle is to small for Tex 135 thread. In thin you need a #22, medium a #23 and thick #24. Here is a good needle to thread reference chart ( https://www.tolindsewmach.com/thread-chart.html ) kgg

-

Juki LU563 stitch problems in reverse

photonashville replied to MikeG's topic in Leather Sewing Machines

Perhaps go up in needle size to 20, 21 or 22 to see if that corrects it. That's all I can suggest. -

Just about everyone on here uses glue. Usually a good contact glue. The make depends on where you live. the brands I use are UHU and Evostick. I also use PVA glue

-

need help finding hardware

stampingdelight replied to stampingdelight's topic in Leatherwork Conversation

-

does anyone use glue with leather working if so, what type of glue has everyone found works best when gluing leather together? or is it not good to use glue with leather?

-

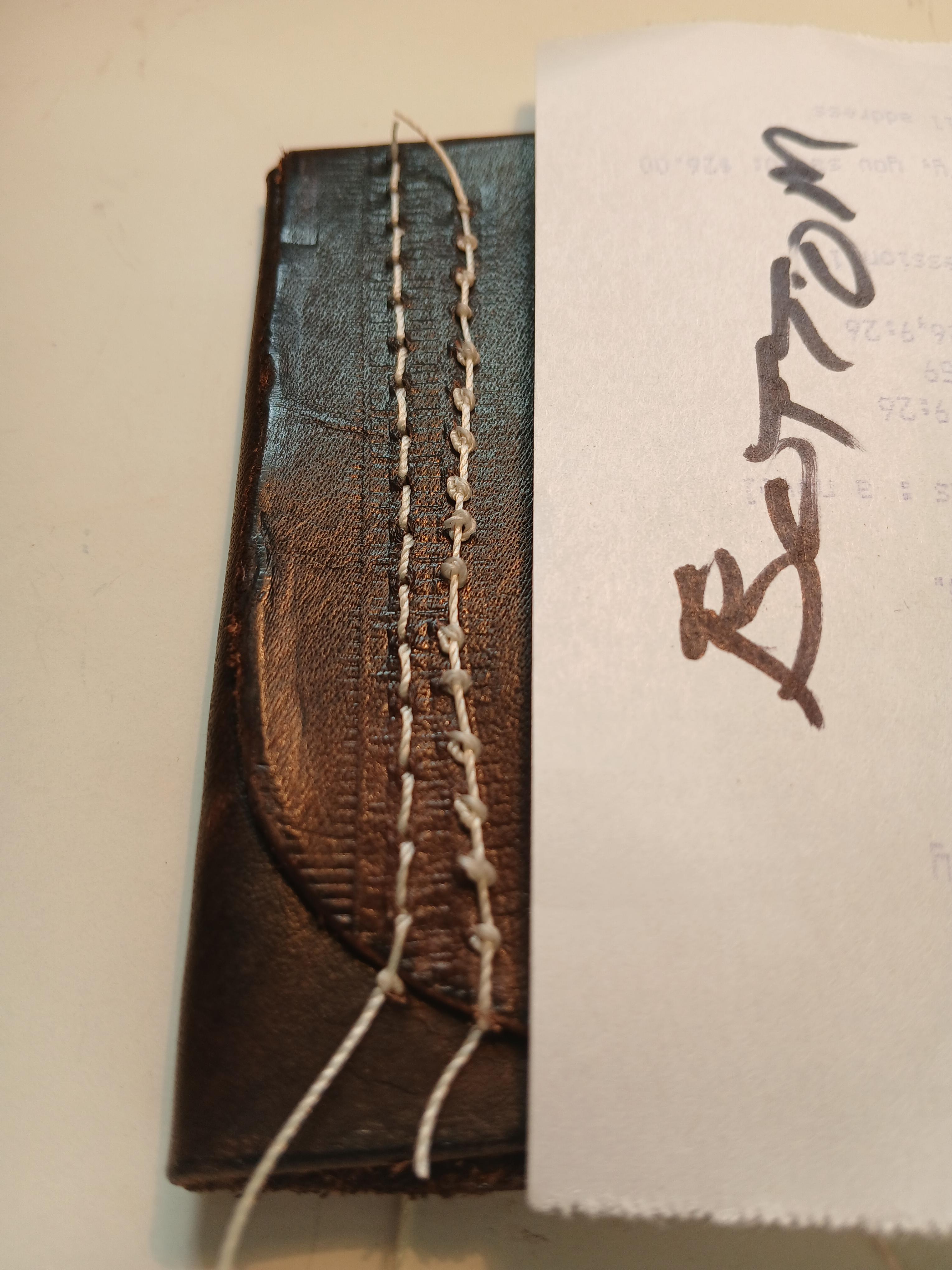

Juki LU-563 135X16X19 needle Tex 135 bonded nylon 3 layers of 3oz veg tan (less than 1/4" total) Stitching forward gives a good result top and bottom (left side in pictures) -- when reversed (right side in pictures), the top looks OK, but the bottom has loops as though the top tension is too loose. Any thoughts where to look to correct this issue? Thanks, all!

-

What ever come about these machines?

-

I can't speak to the machine, but @friquant has been summarizing servo information here. There's so much information on servos here, it's good to have the basics collected in one spot. This is the best site on the internet to learn about all aspects of leather capable industrial sewing machines. Post some pictures of your machine, ask specific questions and you'll probably get a good response.

-

Finished lately one smaller belt pouch. Now I try design bigger pouch, where I can put A5 size drawing block with some pencils. I used cool cow hide with fur on side piece. And here are tracking video too:

-

Annika Sellman joined the community

-

@cmunch Just wondering if this machine is still available?

-

@Constabulary I knew I'd seen one somewhere. Now let's see if the seller responds.

-

ChrisBoehm joined the community

-

Very nice tankards. I used to make tankards but not the authentic looking ones like yours. I soaked them in a chip fryer with hot bees wax. When cool and buffed I would use some masking tape around the top edge and pour brewers pitch (bitumen type) into it and move it around until coated and pout out. Is that what you do or do you mix anything with your bitumen/pitch? Do you make your own patters or are they available somewhere?

-

Zoso72 joined the community

-

Anyone had any luck using one of these for leather… I know it’s a darning machine and I’ll fix it up anyway for use in denim but given the cylinder arm, I’d love to be able to use it for leather. And any recommendations for sites to learn about sewing machine servo motors and restoration?