-

Posts

204 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Beehive

-

Adventures in watch strap making

Beehive replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

This guy gives a good explanation on how to face the holes between two and up stitch lines. -

Adventures in watch strap making

Beehive replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

On the corners. You have to know how to arrange the opposite shape of the holes. Where they meet. It's hard to type an explanation. But there's a certain way to match the corner holes between two stitch lines. To where you won't notice an unmatched stitch loop. -

I spray in a ventilated area in short bursts. The size of items I spray are not that big. Spraying a square foot of leather, in one go, is rare for me. If I needed a particle filter. It'd be a box fan with a hepa air conditioner filter taped to it. As for other things. You can stop by an Army surplus and buy an Israeli civilian, gas mask. Or a, "3M respirator half face" mask. Used regularly in automotive painting. But whatever filter you choose to breathe. You have to back it up with ventilation. You can't spray finish in an enclosed area and think you're not going to be breathing any in. No matter what you're wearing.

-

Adventures in watch strap making

Beehive replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Your stitching looks really good! Another plus with a Bund strap. Your watch doesn't get wrist funk underneath. To where it'll smell. Having to clean the watch every time you take it off. Leather doesn't take an odor like nylon or silicone. -

Most of my life, I've sewn a simple saddle stitch. Never had any problems on either side. Then I had to see what the kids were up to. Watched a video with a guy saying, "You gotta loop it". As he does some fancy needle dance between three hands. "See? That's how you do it." ...his advice had me destroying a project. I didn't give up easy. I looped it two different ways, and it still came out looking like I sewed it, while high on contact cement. I think that's his trick. Either that or the guy needs to open a window. Monkey see, Monkey do, and I hate playing the monkey.

-

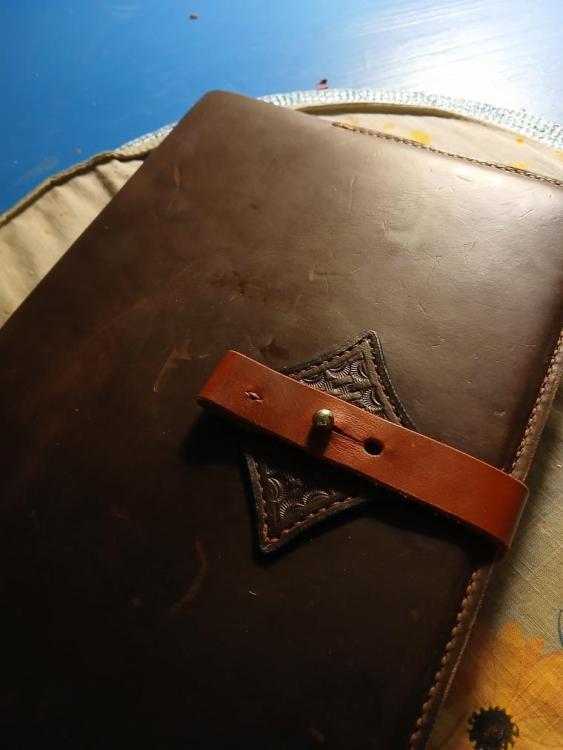

I've made 4 belts in my entire life. All of them are ranger belts. All of them are lined. The current belt project has over 11 hours labor in just the stitching. And for the English point punch. I've used it 4 times. It's nice when you need it. That's if you ever need it.

-

I have a set of half round punches. I also have half round dies you use by hand. How should I put this?....They suck. They're difficult to use and it's hard to leave a clean corner. I've looked at half round wood gouges. Almost the same thing as the Japanese purpose built corner cutter but cheaper and thicker. The only punch I really use is an English point. Vintage Tandy. For cutting corners. I use a rotary cutter. I have a 60mm and a 28mm. On chrome tan, they cut like butter. On Veg, it's not bad but not as easy as with soft chrome. Those or a scalpel. What punch is currently in my shopping cart? A C.S. Osborne Rosette Punch. I'm still debating what size I want. I'm leaning 1.5inch to fit behind the various conchos I make. But if I get such a punch, I'm going to need a brass hammer to drive it. Which is completely out of preference.

-

3M #90 spray adhesive is straight up brutal. I have a can I was using on some upholstery on a older car. It's ridiculous. Better have things ready to go and lined up because otherwise. If the pieces barely touch together. It's done. It ain't coming apart unless you rip it. If I'm lining a holster. It gets #90.

-

Neither did I. Isn't that neat. A divider with a groove cutting head. It even has a wide spot on the other leg.

-

Clean the surface to where you're gluing with a deglazer. Denatured alcohol is common. Also keep in mind. You can use glues not meant specifically for leather. Flexible epoxy for plastics is an option. I've used industrial two part epoxy on a belt liner. Spray activated CA glue. Or UV light activated. But the seam will be stiff. I guarantee 3M has a contact glue that'll hold.

-

I add about a foot and a half of extra thread when sewing something small. I like getting the same handful of thread as I'm tightening it up. I find it difficult when the thread is short trying to repeat stitch tension.

-

Pictures when you start. I'd enjoy seeing what you describe.

-

I personally consider Angelus as a commercial grade. Fiebing as a general use type deal. Is there any difference between the two? Depends on what level either finish will allow oil to pass through it. Fiebing finishes are designed for levels of maintenance you can do. How much it repels moisture. How much it'll let pass or not. Think of a saddle in the rain or a nice purse that doesn't. Angelus, they're big into sneaker shoes. I've tried oiling after I've sprayed. The leather is fairly sealed. I oil my stuff way before it's finished. By the time the Angelus wears down from use. Maybe the item will need more oil. It'll be a while for that anyways.

-

You're welcome. You did good. Now get busy with your next project and grow some more.

-

Then don't ask for areas of improvement. Maybe you should ditch that expensive machine and put some soul in your work. Because.... It-Looks-Horrible.

-

Spraying the hands on a clock you're putting together. Adding leaf shapes to your backpack. If you have any kids or grandkids. Hook them up with airbrushed t-shirt or pillow case. The t-shirt paints are low priced enough, you can go wild. Learn an airbrush. I've tried wiping finish on leather. Acrylic sealer and other things. I make a mess. It looks a mess. So, these days, I only use an airbrush. It really makes things nice. Smooth and even finish.

-

I like the blue stitch. I have some blue thread I haven't tried yet. It's not bad with brown, not bad at all, looks good. The gouge lines really add to the piece. You have a steady hand even if you were using a ruler or not. The bull hide texture inside is also a nice touch. Good Job.

-

I wanted to show y'all this stamp holder. I had forgot where I put it. In case anyone wanted to a go a different route. The end is a ground clamp. Some old screwdriver handle. Polyurethane for a pad and a bolt. It's a weird feeling using it. But it does work. I don't use it...

-

You guys are the best. I'm glad I joined here.

-

I second the alcohol. I use the 91% rubbing alcohol ~after~ a warm soapy water rinse. Holding the airbrush under the running faucet, while spraying and letting it gurgle. Anything left is poured out the cup and then the rubbing alcohol rinse. Leaving a tiny bit alcohol in the cup as it's stored.

-

-

You're gonna need a better picture. If it's a rivet. Do you have any tools like a dremel, drill with a drill bit or unibit? Any files or a hack saw? Removing rivets is a huge PITA but it can be done.

-

The #7 or #8. I can invision it's the same as using a router on wood. Good grief, that's definitely rounding the edge for sure. As for the Montana edgers....micro edges. I'm too heavy handed to deal with below 1mm thick leather. 1/64" means you could edge a thick piece of paper.

-

Adventures in watch strap making

Beehive replied to dirk87's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

And I want you to succeed and be the best. Nothing more. Plus, I don't want you losing a watch either. Giving up making straps because of a spring bar. I'm on your side. -

Respect but the stitching looks awful. You used a hole punch and the thread isn't laying like it should. It doesn't look tight or seated. The stitch distance between holes is too wide. Everything else is awesome.