-

Posts

726 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Go2Tex

-

It's official. The economy is slowing down. We're in a full blown recession. Orders are dropping off. The phones aren't ringing. What plans are you leatherworkers making to cope with what could be a very slow year? Smaller, cheaper items? Different marketing techniques? Fewer shows and less production? Turn the thermometer down, conserve more, drink more?

-

What? No saddles???!!!

-

ditto wow! Love those scrolls. That is SOME knife control.....

-

Huh?? Can you provide a diagram of this? I'm totally confused. Sounds like it's looped around the bar twice.

-

So, here's my dream shop..... 24x24 metal building, framed in and insulated with bat insulation and then OSB panels to cover it up and give me infinite nailing options for whatever I decide to hang or attach to it. The main feature is the 2 4x8 layout tables with room to walk around them so I can get around to lay out my patterns. I can lay out 2 sides of leather at once. Plus, I have a couple of nice big windows to let in light and also to watch the deer cross through the property. Lots of lights and room to store stuff. Still not completed. Got a few inches of wall space left to put up some shelves and work spaces. Have a lookie.........

-

Absolutely incredible work. Now, you just have to find the market for them.....folks that have waaaay too much spendin' money.

-

Pictures from the Boot and Saddlemakers Show

Go2Tex replied to Rawhide's topic in Leatherwork Conversation

Well, it's my own fault. I waited until the last week before the show to try and get reservations and everthing was booked at the better places. I tell ya though, I was sure lookin' forward to hoppin' in that pool after a 6 hour drive from South Texas. But, it's been my experience lately that more and more motels are just closing their pools to get out of having to clean them, I guess. Probably has something to do with the predominance of foreigners running them. Must be a cultural thing.... -

Hey Steve, what does that 7 1/2" gullet on that Wade equate out to on a normal swell? Would you call that about a full QH or just QH? I'm asking because the customer will want to know what he's getting and that's what most folks relate to. It seems wide for a 90 degree bar. Thanks. Brent

-

So, OK the bailout passed and the very next day the market almost dropped off the charts! The entire World economy is tanking and all because a bunch of liberals wanted to spread the wealth around and put "poor folks" into houses they couldn't afford. Of course, that was just to buy their votes and you notice the main stream media isn't talking about that much.

-

Pictures from the Boot and Saddlemakers Show

Go2Tex replied to Rawhide's topic in Leatherwork Conversation

Sooo.... who won the saddle contest? I had to leave early. It's a 6 hr drive and I didn't want to spend another night in that dump of a motel I had. By the way, if you ever go to the Wichita Falls show, do NOT stay at the Ramada Inn Limited. It's NOT a Ramada. It's a DUMP and they closed the pool eventhough it was 90 degrees out. -

Congrats on the first saddle and welcome to the forum! Very nice job on the notebook cover too. I like the carving. May I ask what tool(s) you're using for your beveling?

-

Dude! So how much are they?????

-

hair barrette

Go2Tex replied to jbird's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Really nice work. Thanks for sharing the idea. I was needing some gift ideas that I hadn't already done. So, what did you use for the sticks? I suspect a small dowl, but.... I don't know, chop-sticks? Old knitting needles? Shishkabob skewers? -

The vinegaroon-saved holster

Go2Tex replied to Shorts's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Yeah, the quote as I recall, went something like, "the mark of a master is that you can hide your mistakes. " The trouble is, fixing mistakes takes time and though you may be a master, you'll make more money if you don't waste time. Sometimes it's more cost effective to cut your loses and start over. Been there done that lot-o-times. As for the black snaps, well it's a matter of concealment. The shiney ones are for uniform duty gear. I think most concealed carry guys would prefer the rig not be seen at all. But....it is a nice looking rig and looks quite professional. -

Thanks again for the compliments and tips Keith. I don't have to worry too much about stretch or shrink on my seats down here, although I did get a little bit of stretch on this one. But it has been a real adventure moving from one area of the country where it's cool and wet to an area that is hot as hell and humid one day and dry as west texas the next. It's been weird and hard to get a handle on it but I was very pleased with the outcome on this project. It was slow drying but at least it did finally get there. Last year when we got down here it had been unusually wet and the leather would simply not dry. I have the option of taking the piece outside and letting it take in some hot sun rays to hurry it up a bit. I will definitely follow your advice about not wetting all the way through and just one panel at a time. It will take all the stress out of it, not having to rush one panel before the others get too dry. I also like your advice about the pattern grid look. I'll rework this one with that idea in mind next time. Right now I'm breathing a sigh of relief and enjoying the brief resbit. Got notified today that the saddle cleared customs and was delivered to the customer. WHEW! What a hassle that was. With a huge trade deficit, one would think the government would make international trade easier instead of making it more difficult. It was a nightmare of red tape and bureaucratic BS. But it's history now!

-

Sounds like the same kind of wire brush usually sold with the welding stuff. short, bent, fairly small wires for cleaning the weld, I guess. I use it for roughing sometimes. Usually just use sandpaper for roughing. So yeah, I will definitely try that on the next one. Thanks a bunch for that tip!

-

A couple of folks have mentioned the way I blanked out behind the rear dee. I actually copied that idea from another guy because it made sense to me. That area gets a lot of wear and the tooling will just be mashed down anyhow, so why not leave it blank, sort of like around the front rigging plate. But now that I did it, I have somewhat mixed emotions about it myself. A hard border design might work better for this concept. Appreciate the comments, though, everyone. Thanks for all the ideas and tips.

-

Thanks again for the ideas. Yep, those crossovers is what I was referring to as busy. Just too much goin' on and over and under and it got a bit wild and hard to follow. I saw that as soon as I finished it and looked at the pictures. What do you mean by carding the wool? I think one problem with the wool is that is wasn't really dense and that made it difficult to keep an even trim, but yeah, it could use a bit more work, especially for the pics. Funny, I didn't even notice that before ya'll mentioned it.

-

Thanks for the comments, Steve. Yeah, there is a lot goin' on in there. Maybe a bit too much goin' on. It's a little busy in spots. I'm going to simplify the next one a bit, I think. Always looking to improve it. Now, about that wool..... I actually beveled it back pretty good all around but it just keeps popping back out there on the edge, plus that side pic probably shows it from a low enough angle you're seeing a little more of it. (note to self: order new electric clippers)

-

Aahh, now that's what I was looking for. ....some really good critiques from you Yankees. heh heh. But, seriously, mucho gracias ya'll for taking a good look at it. I agree with your points too. Yeah, the cantle binding....... I use 2 needles, a Douglas awl and blade, as sharp as I can make it, plenty of candle wax to make it slide through nice and easy. I'm using regular machine thread, 277 bond. It matches the machine stitching, and sure is easier to run through the holes, but I guess a heavier thread might help give it a more even appearance. The lighter thread really shows up the imperfections of each stitch. A more consistent pull on each stitch when tightening also helps when I can manage it. That will cause it to look eneven when the holes are actually spaced correctly, I've noticed. (note to self: order heavier thread). As for the cantle smoothness..... Yeah, from the photo it's probably the cropping job, but I did have more trouble than usual cutting it off. I think the problem is trying to cut it off and round it while it's still not completely dry. The seat jocks are cut kinda low and that might lead to the wide appearance from the top view. It's a fairly narrow seat and the rigging and fenders are pushing it out a bit. Guess I coulda got them ears pulled up tighter, though. I sure do appreciate the comments.

-

I thought of you when I was stitching the horn...........

-

All right, all right.... flattery will get you everywhere. What I'm bracing for is some of them highly critical, "ya shoulda got them jocks tighter", kinda posts from the ol' pros. ....... well, ok. Here's another pic that you can go over with a fine tooth comb. ..... ..........well? OK, then, how 'bout this'un?

-

It's a custom order and I'm working now on trying to get it to him. Thanks for compliments, one and all. The shop is really making things soooo much easier. Lots of room to lay stuff down and forget where I put it. The window AC from WallyWorld keeps it a pleasant 78-82 degrees even when the temp outside is a scorching 99!!!!!!!!! Nice thing is, though, it's been really dry. The leather dries out fairly slowly so doing large pieces is not so stressful. I still have to wait for the perfect ripeness. So, I have time to go look for that thing I can't find.....

-

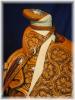

Well, here ya go folks. Put a lot of work into this one. What'dya think? It's a 14" seat on a Timberline Lady Wade, W&C leather, antiqued with medium brown. Hansen's sterling overlay trim.

-

Oh, this is a great topic for controversy. I can't say one way or the other is really any better, although it makes sense the way Stohlman suggests, so I do it..... but I tell ya, it's getting harder and harder to put those skirts on there with all that waste everytime. I sure wish someone could convince me that it don't matter which way they go 'cause they would fit so much nicer with the front of the saddle to the butt of the wool skin, the top of the skirts up into the not-so-good wool of the belly. I could get an extra piece of wool big enough for another skirt layed sideways....... yeah, I know that's wrong but I tell ya, after it's been on a horse for a while, I bet most of you guys couldn't tell which was the butt.