-

Posts

856 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tim Schroeder

-

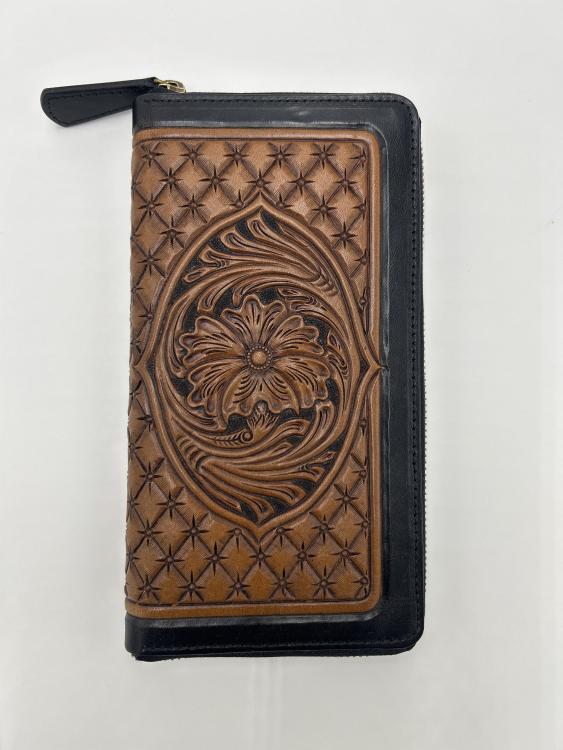

From tracing to finish it took 6 hrs. I ordered a diamond tuck stamp from tuningstar in Bulgaria off EBay. Getting ready to make my wife all new stuff. Purse, wallet, make up bag, check book cover and tablet case.

-

The skin care company my wife works for has a Foundation. They asked to make a wallet for an auction for the foundation. Outside cover is 3/4 oz Herman Oak The inside is made out of some 1 to 2 oz veg tan. So I can dye the inside to match the outside. The dye is 50/50 Feibings Chocolate and Light Brown and then reduced 2 to 1 with reducer.

-

This is the six swivel knives I use now. Leatherwrangler Green Regular 1/4” .0625 for cutting borders. Black 1/4” Ground down to .046 cutting the vines and leaves. Silver 1/4” Ground down to .027 for decorative cuts Red 1/8” angled for the flowers and detail work Craftool 50th Anniversary with a back beveler blade. Barry King 5/8” barrel with a beveler blade and a yoke off some swivel knife from Ebay for smoothing long bevel runs.

-

I usually use a modeling spoon to smooth out the long runs of beveling. I will still bevel and use the swivel knife beveler just to smooth it up.

-

I got a gift card for Christmas so I decided to buy some new tools from Barry King. I called them so I could ask how to use that gift card and Lindsay told me no problem she could probably get it to work. After I gave her the card info she said she would have to wait until she processes the order then she could run the card. She called 4 hrs later and said the card wouldn’t go thru so I told her to just send a PayPal invoice I would pay it. Between the time I gave her the card info and she called me back someone used the gift card for a $1 charge and then a $190 charge at Goat.com. The scams on these gift cards are a real drag. They only charged me $15 shipping and I got the tools the next morning in Texas. I do have 51 of his stamps already. New set of #35 bargrounders 3 15 degree smooth bevelers and a swivel knife beveler blade

-

Sold

-

Do you have PayPal?

-

yes still available

-

Located in Lewisville Tx. $15 shipping to lower 48. Will ship anywhere. Buyer pays shipping

-

I just happened to be in the Ft Worth Tandy today and they have moved the Al Stohlman museum inside the store. Every piece he tooled and she hand sewed is on display. Unbelievable work.

-

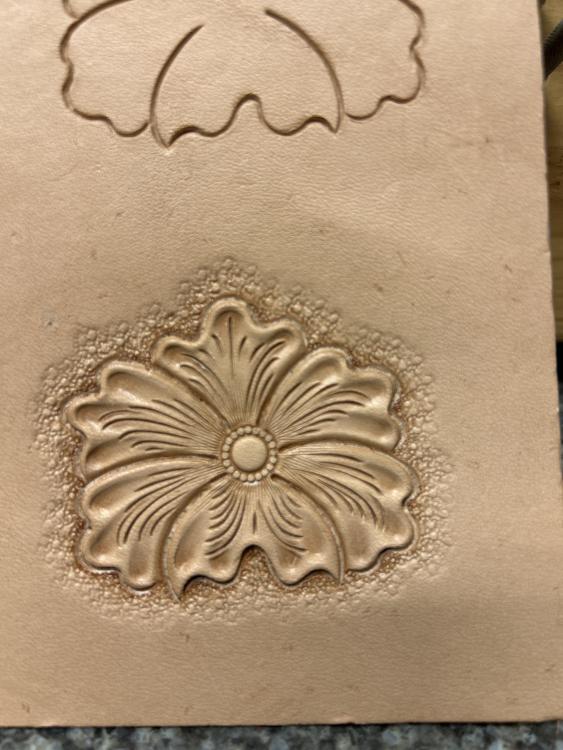

You can see the tracing lines in blue ink. Top one pretty much traced the pattern and the background gets bigger. The bottom one looks much better and you can see how outside the lines I was tracing.

-

Craftool 50th Anniversary Swivel knife. Comes with Leatherwrangler 1/4” straight blade ground down to .044” from .0625 $150

-

Standard thickness is 1/16” or .0625

-

I use a very thin Leatherwrangler blade for those decorative cuts. That thin blade is .028 thick. Standard thickness is .125. The middle one is .042 thick. I cut all the pattern with it.

-

Thanks for the kind words. Correction, the top picture is the Brazilian import, the bottom is Herman Oak. Also working on tracing OUTSIDE the lines when tracing the pattern on to the leather.

-

-

Goal was to quite cutting so deep with the swivel knife, work on bargrounding and keep the background areas as small as possible. Second picture is on some Brazilian import from Frogjelly Leather. Lacks a little color but tools nice.

-

@cord1974 I'm wanting to use Sherwin Williams flat lacquer. I have and can get this veg tan that is super thin for making wallet interiors. I can dye it what ever color to match the outside but need a low sheen finish. I don't like shiny insides. I don't think there is any way for it to crack because I shoot thin layers thru a HVLP gun. I can put it on as thin as I want. I always used Wyosheen for a resist and final finish. It looks better and better the older and more used it gets but it is shiny. What do you use as a final finish? I'm ordering some Angelus Matte finish today. I read to really get a matte finish you need to hit with a heat gun as soon as you put it on.

-

Finished just in time. Made it for a client. Her and her husband have kept me busy for yrs working on their compound. Hope she likes it.

-

-

-

441 Clone stitch length lever adjustment question!

Tim Schroeder replied to Landcruzer94's topic in Leather Sewing Machines

I had to shim the bottom on this 441 clone stitch length lever plate. I took the plate out from underneath the top and started adding shims under the bottom until it hit perfect. Interested to see the adjustment in the base of the machine if anybody shares' that with us. Here's 13 stitches max stitch length forward then backwards and then forward again. -

I have the same CFM under my name and no edit button. Can you tell me what the CFM stands for?