-

Posts

844 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Tim Schroeder

-

Im at home now

-

@MClarkI bought that one from proleathercarvers. I just started using a back beveler and I'm gonna get a Barry King now. I think his are just a little better. I'm gonna work on this and see if I make it a little nicer. Barry King's are twice the price.

-

00, 0, 1, 2, 3, 4 Craftool Pro Edge bevelers. $60 I just sharpened the four smallest. I’ve never used the 3 or 4. They cut really smooth. Located in Lewisville, Texas $18 shipping to the lower 48.

-

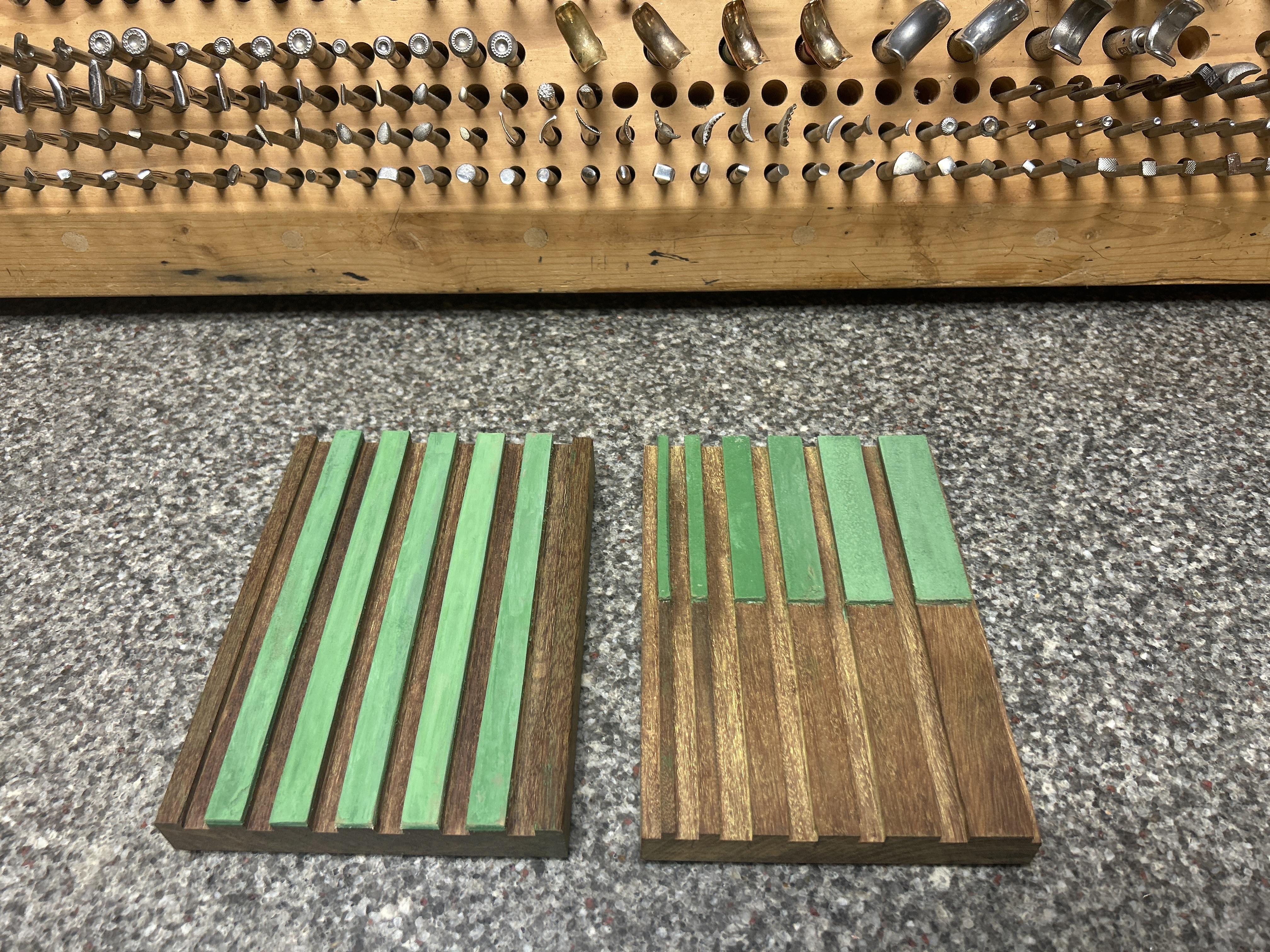

Just built a deck out of Ipet. Second or third hardest wood you can find. Figured some scrap pieces would make good strop boards. I would have run them thru the planer to thin them down but I was afraid it would tear up my planer. Just ordered a new set of edge bevelers so i built a new strop board for them. I had already sharpened my big Gomph French edgers to 3000 grit but just bought a pack of sandpaper from 1000 grit to 10000 grit and have been sharpening tools for the last week. Now I have a sharpening jig and strop that fit each of my French edgers perfectly. Also have the strop wheel on my wet stone grinder. Great for the swivel knife and anything else you can get on it.

-

Checking for the edit button. Yes it is finally back. Thanks @Johanna Thanks @Northmount

-

This is Johanna logged in as Tim checking the problem. Edit button now works. CFM means you can see the part of the forum that was political, controversial and busy, until I hid it.

-

Nope still no edit button. Its been well over a year since some of us lost our edit button. Would also like to know what the CFM for my title means.

-

Just checking to see if the edit button is under the three dots.

-

I haven't had an edit button for well over a year. Just checking to see if it is under the three little dots

-

Thought I read all that post before posting. Still don’t have an edit button. This site does this all the time to me. When I posted the Craftool swivel knife for sale it came up Craftsman Oil when I posted it. Sure would be nice to have an edit button.

-

I have this set I got off EBay. The seller said they were James Jackson’s son and he was selling some of his tools. 1/2”, 5/8”, 3/4”, and 7/8”. Marked Gomph with no numbers. They were unbelievably sharp when I got them. I used them to make the welt channel on boot insoles and they cut thru insole leather like a hit knife thru butter. Now you can almost alive paper with them.

-

And yes I cut thru many times and the swivel knife blades don't like granite. Had to start doing the swivel knife on my cutting mat. Eventually you'll learn just not to cut thru. Then you have good control to get half way when you move up to thicker leather.

-

Tandy had those 2/3 oz. hides on sale really cheap so I bought 2. I made those backgammon boards and all the stuff my wife is carrying right now. I started tooling in the 7th grade and then picked it back up 15 yrs ago. So a lot of practice. This forum and Bob Park were extremely helpful.

-

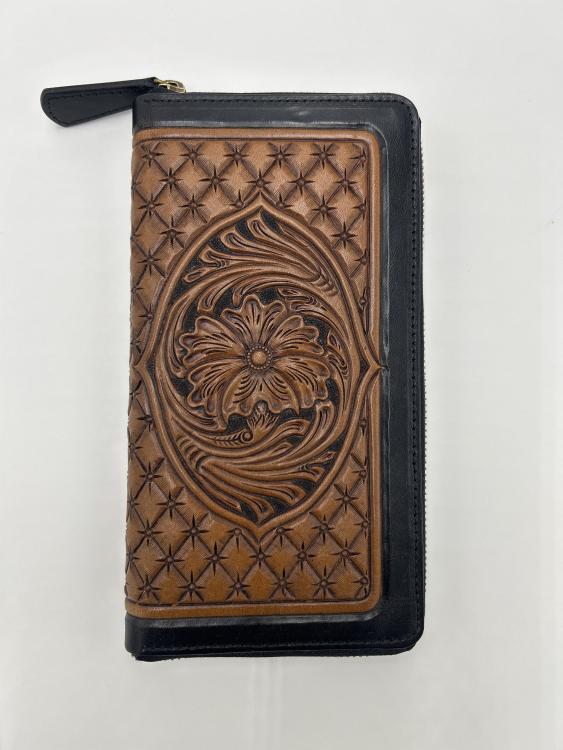

This is the stuff my is carrying right now. All out of 2/3 oz. from Tandy probably 10 to 12 years ago.

-

Both of these are on 3/4 oz. The practice piece is in some Brazilian Import from Frogjelly leather. Practicing on thin leather will teach you touch. In my albums there is some backgammon boards and they are both done on 2/3 oz. The pictures are 10 yrs old so you can’t click on them but you can still see what can be done on 2/3 oz.

-

From tracing to finish it took 6 hrs. I ordered a diamond tuck stamp from tuningstar in Bulgaria off EBay. Getting ready to make my wife all new stuff. Purse, wallet, make up bag, check book cover and tablet case.

-

The skin care company my wife works for has a Foundation. They asked to make a wallet for an auction for the foundation. Outside cover is 3/4 oz Herman Oak The inside is made out of some 1 to 2 oz veg tan. So I can dye the inside to match the outside. The dye is 50/50 Feibings Chocolate and Light Brown and then reduced 2 to 1 with reducer.

-

This is the six swivel knives I use now. Leatherwrangler Green Regular 1/4” .0625 for cutting borders. Black 1/4” Ground down to .046 cutting the vines and leaves. Silver 1/4” Ground down to .027 for decorative cuts Red 1/8” angled for the flowers and detail work Craftool 50th Anniversary with a back beveler blade. Barry King 5/8” barrel with a beveler blade and a yoke off some swivel knife from Ebay for smoothing long bevel runs.

-

I usually use a modeling spoon to smooth out the long runs of beveling. I will still bevel and use the swivel knife beveler just to smooth it up.

-

I got a gift card for Christmas so I decided to buy some new tools from Barry King. I called them so I could ask how to use that gift card and Lindsay told me no problem she could probably get it to work. After I gave her the card info she said she would have to wait until she processes the order then she could run the card. She called 4 hrs later and said the card wouldn’t go thru so I told her to just send a PayPal invoice I would pay it. Between the time I gave her the card info and she called me back someone used the gift card for a $1 charge and then a $190 charge at Goat.com. The scams on these gift cards are a real drag. They only charged me $15 shipping and I got the tools the next morning in Texas. I do have 51 of his stamps already. New set of #35 bargrounders 3 15 degree smooth bevelers and a swivel knife beveler blade

-

Sold

-

Do you have PayPal?

-

yes still available

-

Located in Lewisville Tx. $15 shipping to lower 48. Will ship anywhere. Buyer pays shipping

-

I just happened to be in the Ft Worth Tandy today and they have moved the Al Stohlman museum inside the store. Every piece he tooled and she hand sewed is on display. Unbelievable work.