-

Posts

39 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by farmersracer

-

singer 31 with a little noice

farmersracer replied to farmersracer's topic in Leather Sewing Machines

Hello Slott and bushing oiled - still friction sound as in the videos. Will a 31 be silent in the machine head? Or does it always make these sounds more or less? Does anyone know... The clicking is from the hook. -

singer 31 with a little noice

farmersracer replied to farmersracer's topic in Leather Sewing Machines

Thanks kgg The bushing is fully oiled in the films. Bright as a mirror and shiny. I can spot a small edge in the slot where the bushing is running. I think I will try to make a small bevel at the end of the roller. In that way it will not make contact with the edge in the corner. The slot is polished and the roller is turning freely when the machine is running. I can not see any other area where the sound might come from. Any idéas? -

Hello all:) Just started to restore a singer 31-32 for some leather work. I have noticed a small friction noice from the needle bar roller bushing. Is this ok? This is my first experience with a singer 31, so I don't really know how silent the machine can be. I have made two films. One with the roller bushing, and one with the bushing removed. With the bushing removed the head of the machine is almost totally quiet. Any idéas on how to fix this - or is this not a problem at all? I can live with the sound if the machine can take it. Thankyou.

-

Hello all Does any one know where I can find a good zipper presser foot for a Durkopp 239? Seems hard to find for these old machines on the web. All the feet I find is for newer Durkopp/Adler machines. Are there any other durkopp numbers or brands (like Juki) fitting this machine? Thanks

- 2 replies

-

- presser foot

- zipper

-

(and 1 more)

Tagged with:

-

Hi All There are many companies out there claiming the invention of tin-cloth or waxed canvas:) What I have heard is that the origin is cotton canvas soaked in pure linseed oil. After a few weeks of oxidation the oil will dry and the textile is water proof. The downside is that the clothes also become stiff as cardboard. Eventually sailors and forest workers added fat and waxes, to make the original linseed recipe more comfortable. The recipe I see in posts above are all wet waxes. They will in most cases create a oily surface to the cloth, and the ingredients are quite difficult to mix. In addition to this, a wet wax will melt during the summer time if you leave your cloth in the sun. There is a simpler way to make cotton water resistant. A Swedish company, Fjallraven, has invented a dry wax with only two ingredients. It is called GrenlandWax. It is hard as a brick, and is applied by rubbing the cloth with a GreenlandWax block, and heating the surface with an iron or hair dryer. The recipe has been known for decades in Sweden: 100g parafin 10g beeswax That is all. Add a few layers of this and the cloth will be water resistant. If you are aiming on water proof - use the wet waxes, and apply with a brush.

-

Great to hear I use moo.com They have really good paper options. And if you upload your own pics you can order 100 cards with 100 different pictures. One on each card:) This makes it possible to make very small batches for special products. I use mini cards: https://www.moo.com/eu/products/minicards.html And post cards: https://www.moo.com/eu/products/postcards.html

-

Hi Brian My tip is to use a box that will bring the leather goods to your customer in a safe way. If you want to add value to the experience of the unpacking and first impression: Make a nice tag. It is a lot cheaper than custom boxes, and add a lot of quality for a small cost. I make bags and have two tags in form of custom made postcards. Small items can be taged with business cards. One can tell a long story with a picture and some text.

-

Thanks Mjolnir Hope my english is understandable - pictures are an easier way to cross language barriers:)

-

Hi bikermutt07 Sadly it is a fake:) Kawasaki w650 with a lot of triumph parts. Thanks for the compliments and your frequent activity on this forum!

-

Hi all Just read all about your inspiring workshops. Went out to my cabin, and as soon as I entered I started laughing. I definitely don't have as many useful crafting tools as I can see in your great workshop. It looks as I spent all my tool money on furniture and interiors - feel like a leather-worker-wannabe. I need MORE TOOLS:) Keep posting workshops please - it is great to see them all.

-

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Stetson912 You can find the tannery on this link: https://tarnsjogarveri.com/wip/en/ Some qualities hav a 600ft minimum order because they are not in stock. All the rest is free to order full hides. You need to contact the sellers to get a prize list. Please do - they are great to work with. -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hej ByNelson You are perfectly right. They have no web shop for the leather. You need to contact their sales manegers to order and get a stocklist. https://tarnsjogarveri.com/wip/en/contact/garveri/ -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks ByNelson Yes I buy directly from Tärnsjö Tannery. They are really good to work with. They have no minimum order and good support. -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks YinTx Sadly the burnish is spreading from the edge to the surface of the leather in an uneven pattern. This is one of the reason I only use wax on the edges. I might try heating the edges on some models in the future. -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hello A6C507 The maps are installed before sewing the parts together. Special tools for these snaps of course. No moving parts in the chrome studs, so I don't thing they ever need replacement. Scovill.com have got studs with thread mounting though, but they will take up too much room inside the bag. -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Hi Tugadude Haymaker = farmer, and in Sweden motocross and racing motorcycles on gravel is big among farmers:) -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Matt S Great etsy page you got. This mold design is great to start with: large objekt with little depth. I am planning on a smaller version as well. 1/2 the size and twice the trouble:) -

Molded document sleeve

farmersracer replied to farmersracer's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks Stetson912 Yes it is about 8/9oz. But i think it is slightly thicker. In Europe we use a mm system, and this leather measure 3,5-4 mm. I have used a very flexible veg tanned leather from Tärnsjö Tannery in Sweden. They made a small batch of extra fat, but not oiled leather as an experiment. It is a bit to flexible to use in a sewing machine, but turned out to be perfect for molding. It keeps the shape perfect, but has no dry wood feel to it. -

Thanks Northmount This makes perfect sense. I have used a iron enamel tray when soaking the leather. I also sand the wood mold before using it. There might be a nail or two treating metal dust. Thanks for the help

-

Hi all This is my first molded leather (and hand stitch) project. Yes, a 13" mac will fit, but the goal is to use the sleeve for maps and documents in farming and forestry. I have used veg tanned leather and is at the moment testing different oils and waxes. Saddle stitch with waxed linen thread 18/4, pricking iron and owl. I can really recommend the buttons from scovill.com. Have been using them on waxed cotton and leather bags for 7 years. Their designs are one bit more robust than most brands. They come in black or chrome - the ones you see in the pics have been stripped from their black paint. I have decided to use only a blend of bees wax, coconut oil and olive oil on the edges. No burnish or color, just to bring more focus to the surface and less focus to the edges. I am new to wet molds, and have a few problems with keeping the veg tanned leather clean during the drying process. Does anyone of you use any coating on the leather before soaking and forming the parts? regards Lars Gustavsson

-

Hi I have just started to wet form veg tanned leather. But I get lots of tiny black spots on the leather. I can definitely say that they are not there when I cut out the dry leather parts. What is this - something in the water, the leather or the mold? Thanks for all tips. Lars Gustavsson

-

Thanks Owe Great films that will be useful for the timing. One question: I have used the small vertical gear to adjust the hook timing. Is this a problem, or is it ok? Regards farmer's racer

-

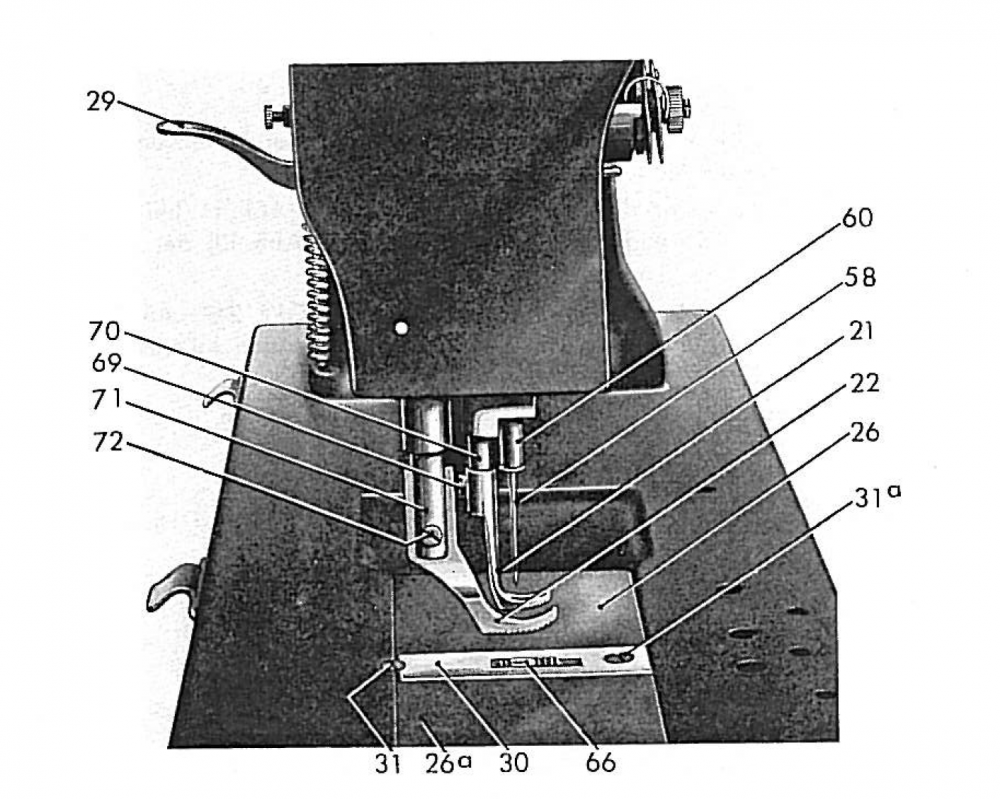

Thanks Owe for the tips. And I have to confess that a assume that the machine has a good timing because it make good stitches:) I need some help here to make it run perfect. The manual of the Consew is spot on the same as the Dürkopp. I have worked a lot with timing of the needle and the shuttle - these adjustments I know about. But the feeding, both presser feet and feed dogs are new to me. I work with the same machine in different thickness and various materials. But the most common thickness is 1/4 inch leather and canvas - I will start here. This is pictures of the machine. And I have also added som drawings from a german manual, with numbers that might be useful for orientation. Regards LG

-

Hello every one I am using a durkopp 239-525 to sew leather bags. The machine has been geared down to slow speed. But has started to break needles. I wonder if I am starting to reach the limits of this machine when I am sewing a stack of 8 millimeter (1/3 inch) mixed materials? Waxed cotton and veg leather. The machine is feeding good and makes the stitches in a nice way. I am using 130 size 21 needle I have noticed that the needle is hitting the material before the walking foot. When the walking foot is reaching the materials the needle has reached 6 millimeters into the materials. Is this a timing problem - or is this ok? The rest of the timing is great. Do I need a bigger machine or is the durkopp 239 good for this work? This is the needle in the highest position: This is when the walking foot is in contact with the feed dog: When the presser foot is moved up one can see that the needle is 6 millimeter into the feed dog: The materials is veg leather and waxed cotton in a 8 millimeter stack: Seen from the front one can see that the walking foot is not in contact with the material when the needle hit the fabric: