-

Posts

874 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Rossr

-

So I recently.bought some leather tools stamps, overstitch wheels, lacing chisels usual stuff, but this tool was in there. Is it for leather? Anyone familiar. In the handle the part the top Screws into actually is a wood screw that was drilled and tapped to take the head.

-

Where do I go from here?

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Bill. Rocky Aussie. Thanks for the thoughts and taking the time to respond and look up that thread beautiful work there btw. I really appreciate the constructive criticism. Which is exactly want I wanted and needed to help me improve. Regarding The different color thread. So I used different machines for the stitching. The overlay on the eagle sheath as well as any stitching for the deer skin liners I do on a flat bed. Mostly my singer 111w155 with 69 thread. Mostly in black. The white thread Is linen and being done with a old campbell randall needle awl machine. l personally like the white thread contrast and maybe that is something I keep doing to set apart what I do sheath wise or make that my thing? I have thought about setting the machine up to so other thread in colors in nylon but have not attempted that. Mostly because the linen works. That machine has been running linen for a lot of its life in the previous shop. I liked the stitch it was set up with and I just keep doing it. I also Know I will need to get different needles and awls and fiddle around till i get everything sewing correctly. On the spacing issue. You are correct. So my general process is I sand the edges before I stitch. So they are close to finished. Everything is glued together. 3 pieces of leather. Front, back and welt. Many times 7 to 8 ounce for front, back and welt. I have used a guide on the needle awl machine. But sometimes I have trouble maneuvering especially around the tip on the turn. Also depending on the thickness I have to be careful about keeping the needle and awl going straight and not wandering off to one side. So I have either free handed or I will take a wing divider and run a line around to follow. Once it is stitched. It always seems I need to do a bit more sanding . Sometimes the welt will move a little etc. I try my best to honor the stitch line as I want it to be uniform. I also really like the stitch front and back on the needle awl machine. Currently I have no other machines either that will stitch that thick. Regarding Google. I agree so much to look at and see. Sometimes I try and avoid this because I find myself copying the styles too much and maybe not developing more on my own. I realize this is a catch 22. As they are sheaths. Been around forever and not like we are reinventing the wheel here. The basics of a functioning sheath do not change much in my opinion . The adornment does is all and how we choose to fancy them up. Be it exotic leather inlays etc. In regards to practice and different styles. I have gotten to where I am by doing that of course. Hard part for me is getting enough knives to do that. I can make knives of course too. But I am a lousy marketing and sales guy. I truly enjoy making sheaths and would love to have more of this work in my shop. However. Once you crest a certain point the price point is higher than many are interested in paying which I understand. In my area locally anyway many people cant understand why I charge $50 for a basic pouch sheath. Between leather costs and time though that is a reality. Many times the knife they want a new sheath for isnt worth $50. But is special because it was a family members etc I understand the balk. I am not even sure my work is good enough to enter the higher end custom knife market or even really how to find that line of business. But I am happy to keep making them when I can. @Tugadude I will do my best to keep updating this thread as I do think this is valuable information. We are all trying to improve and find our own mix of style. Leather work has been around a long time and we all share our knowledge on here which is wonderful and helps keep the craft alive. I have a zillion more thoughts but that is enough for now. Ross -

Where do I go from here?

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Appreciate the thoughts. I believe that's where I am at, how do I find my look. Paul's sheaths above has that. You can pick his sheaths out easily. I do agree it takes time . It is hard and we are all building on what others have done. Ross -

Where do I go from here?

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks for the thoughts and the response. As always your sheaths are beautiful. I actually.have all 4 of the videos. I'd recomend them to anyone. Without question they helped me improve. I have done more Pouch sheaths than anything. But have also done some other styles. I enjoy making them and am always looking to improve. Hence the question! Most of the sheaths I make are for knives I have made and many are drop points hence the Pouch styles. I have done some inlay work and overlay too. I occasionally get hired to make sheaths for knives too which is nice. Thank you for offering to share your knowledge. Very kind ! Below is some other sheaths I have done Ross -

Where do I go from here?

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Chuck. Thank you sir. Kinda like the period sheath idea. -

So I've been making sheaths for a while. Most of what I make can be attributable to Paul Longs video series and many Thanks. @sheathmaker I'm pleased with the function and look of my sheath work. But what next. I've done carving work, I've done inlays too and overlays at times. But I've been trying to think what else can I do to stand out and improve from here? Looking for constructive criticism Thanks Ross

-

Buck 110 Pancake sheaths

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Very Kind. Thanks -

Trying to learn video making skills... warmup video, comments welcome please!

Rossr replied to YinTx's topic in Show Off!!

Seemed smooth to me and the slow down and speed up was nice to show detail and then speed up so you weren't bored watching the same process. The black color on the subtitles seemed to blend a bit with the granite. Maybe a differnt color would be better. But it was readable. Music was nice and seemed to flow. Just my off rhe xuff thoughts Ross- 31 replies

-

Buck 110 Pancake sheaths

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks folks. -

So what do we think of this sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I do like the backstitch option better as well, thanks for the thoughts! Appreciate the compliment. Very kind, thanks tug -

Hi sorry I missed this post. Yes it is still available. There is a stitch adjustment on It but I didn't play with it much. The machine weighs 58lbs . So I added 10lbs for box and packaging 68lbs and did a usps price check to phoenix AZ, came up at $148.70. There may be cheaper options not sure. Thanks Ross

-

So what do we think of this sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks -

Buck 110 Pancake sheaths

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I also use the tip of a deer antler seems to help. Along with saddle soap or a bunch of other possible things like gum tragacanth etc etc. Best I can say is try stuff. There's lots of ways and everyone finds a method they like best -

So what do we think of this sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

So that's a possible for sure. I interesting you bring this up. I sewed the white linen stitch on my needle awl randall campbell machine. One of the issues I have had is how to back stitch, if I just back stitch the awl will cut the thread . In the past I have left long tails and then hand sewed them foe the back stitch. This of course takes time and annoys me. So I saw the loop or u turn in I think AL stohlmans book on holster making and tried it on this one. Not sure it's a good method or not. Ross Thanks -

So what do we think of this sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I appreciate those thoughts. Less is more many times and I sure do add too much at times. Good thoughts on the stamps with detail too. -

So what do we think of this sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Appreciate that thought Fred. Im always hyper critical of what I do.....I suspect I'd stop making stuff if I ever made something I was 100% happy with....I think I'm trying to figure out how to progress more. I see amazing work and while I'm not unhappy with mine I'm hoping I can Still improve. Bert and chuck thanks for the kind words -

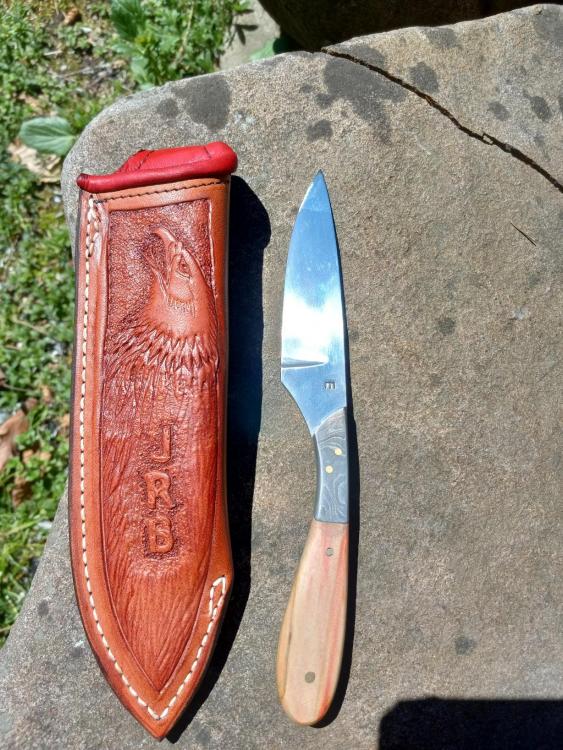

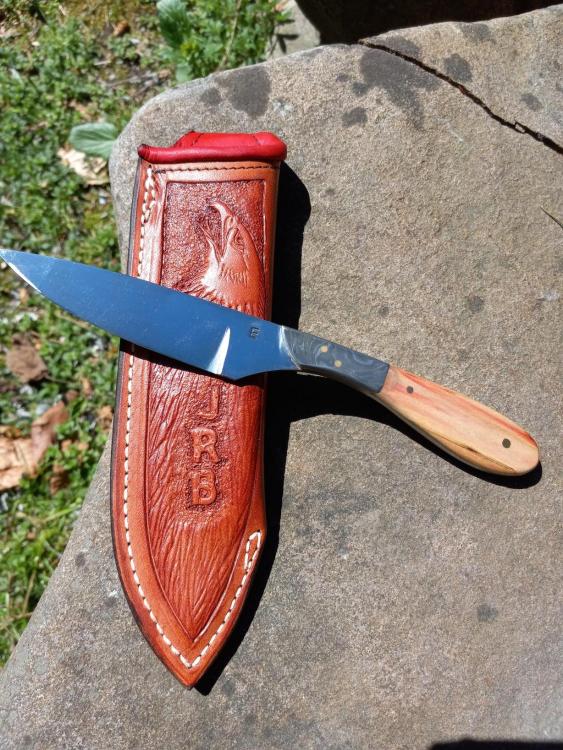

I made this knife and sheath combo for a friends son who earned his Eagle scout rank in boy scouts. I carved the eagle head and then tried to blend it so as it went down the sheath it seemed like the body. Kinda abstract maybe but with the Initials thought it flowed better. I feel like my carving skills are rusty at best but can't decide how to improve on this one. The eagle head is from a craft aid. The eye was tough imo and around the beak seemed off to me...among.other things Open to thoughts Ross

-

I'm still looking for the wood badge ones I have 3 is all. And I'm always looking for the 2 eagle scout one. That being said I do really want to hang onto this one.

-

Cs Osborne Newark Round knife sheath

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I was happy with the front stamping and I agree it's so easy to get off with those dragon scales, So the pin, depends on if they are peened over much or not. In this case I was able to take a punch and tap it out. I did knock a small sliver of wood off the handle doing this which I glued back in place. Another possible is to center punch the pin and then drill it some then punch. Never had much luck there. Lastly a dremel with a small bit can help if it's deformed a lot. Grind it away and then tap out. To re do it I have several brass rods around and just pick the size that fits epoxy the blade into the handle and some epoxy on the pin. Tap next through. Lastly I will file or sand the pin down till its close to each side of the handle. Then peen one side then the other. I use a anvil but anything hard will do like a piece of metal. Go slow so u don't Crack the handle. Then I sand it down and polish it. Sometimes I will drill the hole a size larger if the pin came out lousy. Assuming the hole in the metal part can be drilled. Meaning the metal isn't hardened. hope that makes sense Ross -

I've had this knife kicking around in a drawer for a long time. I never could decide if the shape was a factory style or reground at some point , I lean towards it was reground. Anyways I had taken apart the knife cleaned it up epoxied and repinned it, So I slapped this sheath together tonight on the quick.....and yep mistakes were made. For some reason on the backside I decided run a border line before I sewed...I know better cause when I sew it they never come out even on the back. Then I swore I had my makers stamp centered...not so much.....and lastly one snap is off compared to the other. Oh well still looks OK and will guard the blade which was the goal. And maybe I'll make another for it some day. No matter how many things you make or how far you come some days they remind you where ya started lol

-

Looks like a nice package to me, compliments the knife well imo! Nicely done Ross

-

Listing this for a friend. These are all craftool usa co. They are from the 1970's is when he was leather crafting. All are in good shape imo. On a quick count there are 147 stamps, 8 modeling spoons. 2 swivel knives and another swivel knife missing its screw to hold blade. Asking $700 obo plus shipping. Everything pictured.

-

Buck 110 Pancake sheaths

Rossr replied to Rossr's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Chuck