-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Posts posted by garypl

-

-

3 hours ago, Carson said:

They are the same product but the 4500 table wables when in use or so I have seen.

You must have seen a defective unit - I don’t use the table very often, but it is solid as a rock when I install it!

Gary

-

Hi Gus - nice looking holsters! Only comments I have are that I am not a fan of using rivets at the corners as reinforcement. I think the glue and stitching is sufficient to keep the holster together. The middle holster retaining strap could use a slightly longer strap to make it easier to grab. Good job!

Gary

-

Thanks for the information Kitten - I downloaded the trial version and am anxious about trying it out. I have played a little with other CAD programs and decided the learning curve was too long for me!

Gary

-

1 hour ago, Carson said:

I would get the class 4 it would be better than the 4500 b/c the 4500 wables and the class 4 doesn’t plus the class 4is Built like a tank. Buy a new not a used unless you are or want to be a sewing machine mechanic.

I thought the Class 4 and CB4500 were essentially the same product. I have a CB4500 and love it - not a bit of a problem over the past 9 months.

Buy from whomever you feel comfortable dealing with.

Gary

-

10 minutes ago, BillinTR said:

Just for curiosity I would like to know what the approach should be if you specifically want to copy something functional. There is a leather item I use regularly that is no longer made. There are a number of other simple functionally identical items available but the one I am interested in is uniquely constructed and that contributes to why I like it. I know for certain that the original company no longer makes the item which is why I am going to make one for myself. But I also know of a number of other people who happen to like the same version of this item that I do. I have considered making additional copies just to perhaps sell a few. We are not talking about a huge market. Just maybe a little pocket change to help support my interest in leatherworking. What is the predominant thinking on this?

If you are not actively trying to market a product and just want to make a few for friends, I would not worry about it one bit.

Gary

-

1 hour ago, Webicons said:

Do yourself a favor and put a dab of threadlock on the threads that hold the brass applicator. On two separate occasions it came undone and had to fish it out of my bottle. Good thing that I can use chopsticks pretty well.

Thanks for the tip!

-

You do beautiful work Tim! How thick is the belt with liner?

Gary

-

7 minutes ago, bikermutt07 said:

Lisa Sorrell uses a sewing machine for boot tops. I would say those boots are hand made.

People have expressed here before about...

How a market won't really bear a price difference in hand stitched vs. machine stitched.

Because at the end of the day, the end user doesn't know or care about the difference. They bought a hand made leather item that should last at least 2 generations (with care).

Machine or hand doesn't really lend itself to the end scenario.

That being said, you can inform and educate your audience. And maybe they will be willing to pay more for hand stitching, but the real argument boils down to how popular or "in" is your product.

When it comes to sales, the most experienced salesmen will sell on emotional connection. Not construction techniques.

One needs to sell the experience of having a favorite bag that only lasted 6 months compared to the bag that went on all the adventures with them, that now they can pass on to one of their children.

See the difference? Well made is well made. But the sale comes from connecting on the clients' level.

Well said Mutt - at the end of the day you explain the options to your customer and give them what they want!

-

3 minutes ago, alpha2 said:

It they'd said hand stitched, that would be different.

If I roll out the hide, cut it out with a round knife, carve it or stamp it, as opposed to using an embossing machine, then dye it with a dauber, and buff it with a cloth, bevel the edges with a hand beveller, burnish it with a wooden burnisher by hand, then stitch it on a Cowboy 4500, you can bet it was hand made. Then machine stitched.

Good point alpha - I think there are many people who don’t know or don’t care whether a product is hand stitched or machine sewn! Some might consider machine sewn to be stronger even though saddle stitching is normally more durable.

Gary

-

4 minutes ago, robs456 said:

Mine neither it seems, the big brands get away with murder.

Launching my brand as 'all handmade', seems like that might not be worth as much as I thought...

Perhaps it would be easier to brand your products as “custom” or “made to order” to differentiate from mass produced products.

I agree with Mutt, if you are making a product from start to finish by yourself, I would classify it as being handmade, regardless of your use of a sewing machine or other “modern” tools. Again, just my opinion!

Gary

-

Nice job sewing everything together!

-

Looks very rustic - what leather & thread did you use?

Gary

-

35 minutes ago, skinhacker said:

Just joined as I have more time on my hands and will be taking on a few more projects. Started leatherwork in 1972 as a child. Friends dad was pretty slick at making purses and belts and this was a high time for native American and western stuff. Well after a few years all my stuff was packed in a box I had made for my 8th grade woodshop class and girls and cars then career took over. well about 5 years ago I wanted to show my son a few things and spend some time teaching him what I knew (which is crude crafting of utility items).

Hope to share and learn as we all stand on those who came before us.

Welcome to the club!

Gary

-

2 hours ago, Sceaden said:

It's a relatively uncommon but very useful accessory.

Historically there is almost nothing to go on as "lock covers" are referenced but not described and I don't think there are any surviving examples.

The idea with these covers is to create something that is accurate in design, materials, and style which didn't necessarily exist but could have.

Track of the Wolf is a great muzzleloading supplier and they sell lock covers as well as patterns for lock covers. See this link: https://www.trackofthewolf.com/Categories/PartDetail.aspx/112/1/LOCK-COVER-L

Gary

-

1 hour ago, bikermutt07 said:

Never heard of these. Is it for rain protection? Or maybe to keep the lock from getting banged up in a wagon?

Or maybe it's just a hillbilly safety.

Looks great.

Main purpose is to keep rain and snow out of the primed flintlock - not conducive to quick shooting though!

-

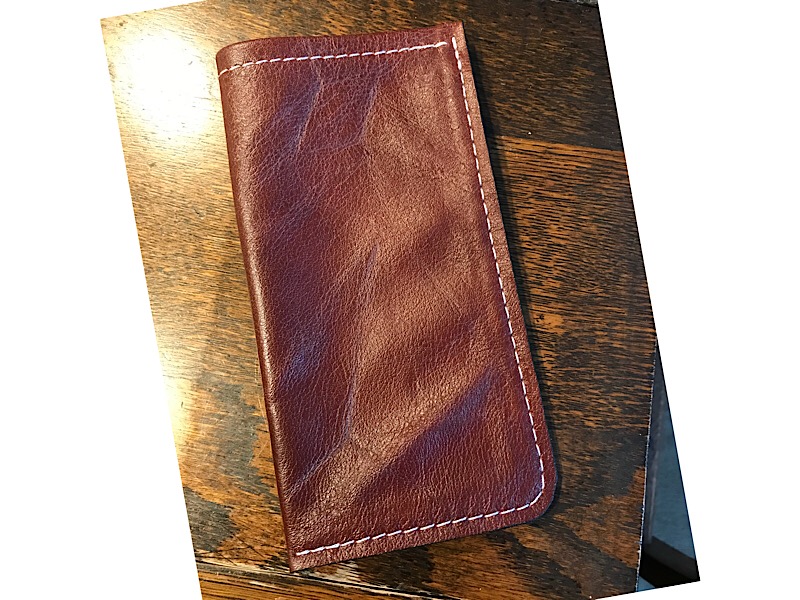

Here is a recent wallet I made.

-

Nice job! Don't see these in use very often!

-

1 hour ago, Sceaden said:

Good looking bag! I started into leatherwork over a year ago to make myself flintlock accessories. Over a year and few grand in tools and supplies and I still haven't made a possibles bag. :-\

That's why I started playing with leather back in 1969 - to make accessories for muzzleloading rifles! Don't shoot them much anymore, but still enjoy playing with leather.

Gary

-

Sorry to hear about your shipping issues - that's a bummer! What about just stitching the strap to the side of the bag? Alternatively, to relieve stress on the leather could you sandwich one or two small metal washers in the leather, run the rivet through them, and then cover washers with leather to hide them? Would that distribute the stress around a larger area?

Gary

-

I never tried this, but I suppose you could take a copper rivet and carefully drive the burr down until it is not quite touching the material and the rivet is still free to turn. Then peen the rivet to keep the burr in place. Try on some scrap and see if it is loose enough for you. Long term I don’t think this will wear well and I suggest using a small D ring instead.

Gary

-

I glued two pieces of wet veg tan together with Weldwood contact cement (red can) just to see how well it would hold the wet leather together. To my surprise it seemed just about as strong as dry leather when using the same glue! Test it for yourself.

Gary

-

I make simple eyeglass cases and everyone really likes them. Basically a piece of folded leather, tooled or not, fold top edge over on the softer cases and stitch. Then stitched on bottom and side and done! Here are a couple of examples.

-

On 1/18/2018 at 10:31 PM, garypl said:

I never tried SLC before so I just ordered 50 feet of leather from their “disrupters” sale. Mostly thin lining leather and calfskin. I am looking forward to checking out the quality.

Gary

Received 50 sq ft of leather today from the disrupter sale - nice pieces of lining leather in pieces varying from 1.5 to 3.5 oz. I am very happy with the quality, price and quick service from Springfield Leather!

Gary

-

Nice work Forester!

Gary

.jpg.d60258221c476480a6e073a8805645bb.jpg)

A couple more recent projects

in Purses, Wallets, Belts and Miscellaneous Pocket Items

Posted

Very nice work!