-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

Nice rifle! I would line your case with some canvas - shouldn’t cause any problems with the finish rusting.

-

Using an arbor press on solid copper rivets + burrs?

garypl replied to ColdEye's topic in Hardware and Accessories

I use a small ball peen hammer to round the edge after cutting the rivet. Much quicker and easier than using the tool. -

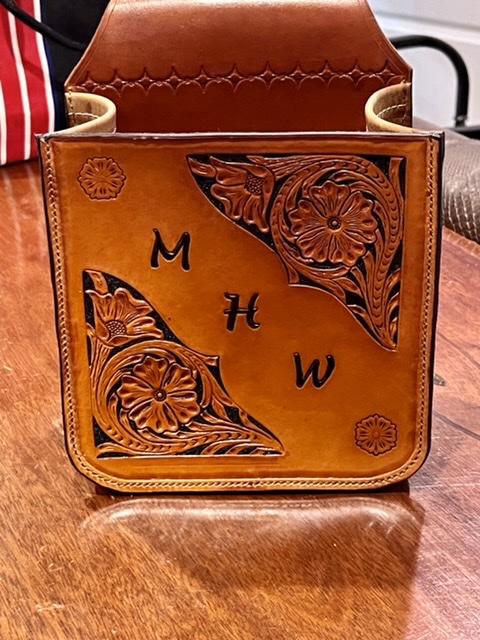

Finally Finished Shotgun Shell Pouch

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks to everyone for your kind comments! I used bison for this very reason - very strong leather, soft temper and easier to bend around curves. I use a very fine tipped artist’s brush and carefully dye all the black background and letters. Took a couple of hours to finish this one. very nice work! -

Friend asked me to make him a shot shell pouch when I had time. Finally found some free time to finish it. Front and back panels are HO 7-8 oz and gusset is 4-5 oz bison. Saddle stitch the gusset to the panels but used my machine to sew the back flap and gusset folds. He likes it. Now he wants a belt!

-

Rifle Scabbard

garypl replied to pmieras2000's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Beautiful job - you should be very proud of making something that will be a keepsake for him! -

Consew 206-RB4 oiling mechanism and sewing speed?

garypl replied to sojourner999's topic in Leather Sewing Machines

Buy them on eBay - I bought a complete tensioner assembly for @$16 a year or so ago. Probably a bit more now due to inflation. -

Called blocking or the easiest way to do this is to airbrush darker dye around the edges.

-

It does fit an N frame with the thick welt and I used it in a match this past weekend - carried a S&W 38/44 revolver just fine! I just wouldn't sell it to anyone! Going to start another holster and make my own pattern this time.

-

Put the handle in a vise or wood clamp outside that will hold it upright. Take an ingot and a propane torch and hold the ingot over the hole in the handle and start heating it and let the molten lead drip into the handle. I do this all the time when melting lead for bullets and the pieces are too big to fit in the pot. Easy to control and very little fumes.

-

Looking good! Sounds like it was an interesting project.

-

Slicking inside of holster

garypl replied to MarlinDave's topic in Gun Holsters, Rifle Slings and Knife Sheathes

This is a great idea! -

Latest bag commission

garypl replied to Bogwot's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

You made a beautiful purse there! -

I have a couple of knives from Terry Moore that are very nice and sharp. Very well made and good looking to boot. They are a little thicker than some of the other knives. Pricing is very reasonable as well. https://leatherworker.net/forum/profile/1667-t-moore-medicine-hat-saddlery/

-

Colt King Cobra holster

garypl replied to dakotawolf's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Nice job - he will love it! -

Thank you - I think I will use the same design for the carving, just make the whole holster a bit larger.

-

Chuck - I did make a heavy paper pattern and thought it would fit easier but obviously I miscalculated! I am going to use a similar patter again but this time I will expand it another 3/4" around the edges and trim after I sew.

-

I normally do go very slow but I think the main problem is sewing too close to the edge on this thick of leather. Next time I will leave the back piece wider to provide the extra support and hopefully will have a better result to post! Yes & Yes - need to make it wider for better support - made a mental note to myself about this, now if only I can remember it!

-

My dog is so small she would have a hard time fitting it in her mouth! Thanks, my scrap pile has a few tooled pieces to remind me how not to tool!

-

I think both of your comments are right on. I was trying to keep the edge perpendicular but when the edge is that thick it doesn’t take much of an angle to end up coming out the edge! I did use the pattern from the How to Make Holsters book and I agree that it is a bit small for an N frame. A friend of mine suggested adding 3/4” to the pattern dimensions to allow for a thinner welt and to move the stitch line in a little more. Always learning something new…

-

Well I was almost finished making a holster for a customer’s S&W M29 revolver and when I sewed the seam things went south quickly. The thickness I was sewing was 3/4” with two layers of really hard temper veg tan for the welt. I was using 346 thread and #26 needle in CB4500. About 1” into the seam the needle deflected and came out the side, hit the needle plate and broke. Tried it again and deflected again - the leather was so hard the needle was bending. Finally gave up, removed all the thread and hand sewed it, but the damage was done, so I am keeping this to remind myself not to use such a thick welt. I used a pattern from Stohlman’s book for a 357 revolver and I think it might have been for a K frame and not an N frame. This is why I added the thick welt so the N frame would go in far enough. Lesson learned - I will make my own pattern for the second holster and add a little width to allow use of a thinner welt. Live and learn!

-

You made a nice case there! I like to make cases from soft temper leather - I like to use elk hide. Sew the case inside out and then pull it out so stitch line is inside. I double stitch using a machine but I think a single saddle stitched seam would be perfectly adequate. Here is a pic of an elk hide case. Gary

-

Do you bevel your edges before applying dye and what applicator are you using? I find it easier to dye edges after I bevel them. I use a felt chalkboard eraser cut into small pieces and held in a spring clothespin to apply dye. Dip the piece of eraser lightly into dye and apply to edges. Don’t soak the eraser - just dip the tip and go slow and you should not see bleeding onto the back.

-

Nice job with the card! Good that the year is not on it so you can reuse it!