-

Posts

1,642 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by garypl

-

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

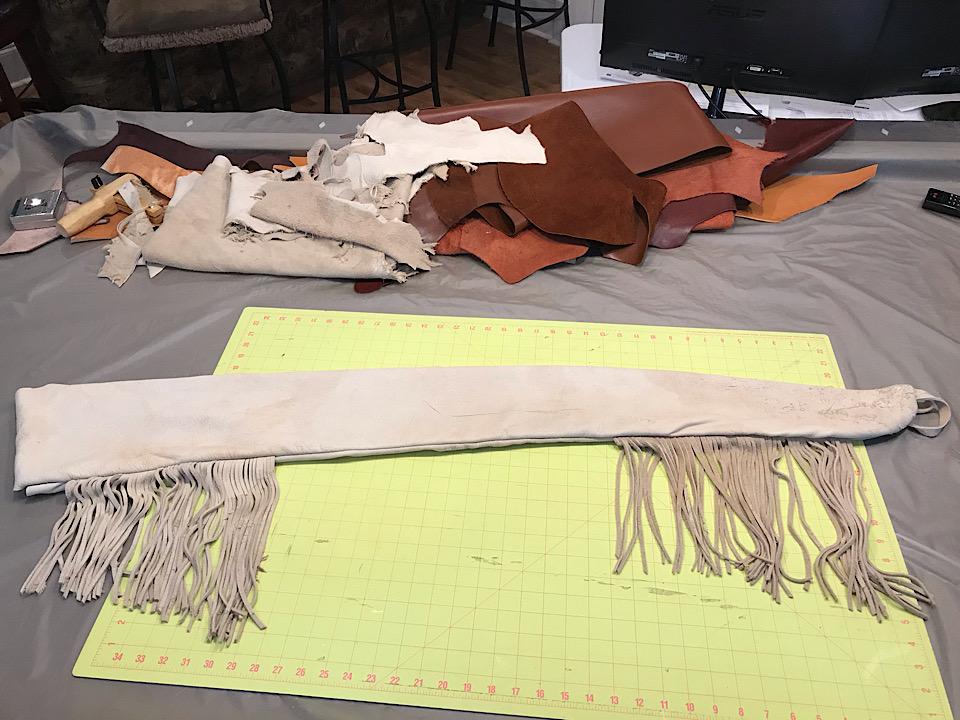

Hey Brian - what model new printer are you going to buy? I have to buy some more PLA to print guides - spools are getting empty! I keep trying new leather for rifle cases - this is some 2 oz pull up leather - worked well, but once I turned it inside out I don’t like the fringe - flesh side is lighter, so I am rubbing leather balm into the flesh side to darken it up. Lesson learned - next time I will darken the flesh side before I cut the fringe - much easier than doing each strand! Gary -

Glue leather belt

garypl replied to Davm's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Best way to glue liners, in my opinion, is cut the liner oversize, glue it to the top leather, then trim the edges. Pretty easy. Gary -

That’s how we learn from our mistakes and I have had many! Like I said, maybe experiment with some scrap leather before you bugger up your journal.

-

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That is a cool looking bag! -

Tooled Braces/Suspenders

garypl replied to AlexOstacchini's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Beautiful job Alex! -

I suggest you take another piece of leather and apply the atom wax, just like your journal. Then test the paint you plan to use and see how well it sticks. Another suggestion is to take some denatured alcohol and try to strip the wax before painting - this should be the preferred method, but again, test on some scrap to see if you like how it looks before you mess up your journal. Acrylic paints seem to stick to many types of finishes quite well, but I would be concerned about durability when applied on a waxed surface. Nothing to lose by testing first on some scrap! Gary

-

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Brian - I will try the settings you suggested. I’ll let you know how it works out and if I have any questions. I appreciate your help! Gary -

I have been ordering more thin lining leathers and oil tanned leather from Springfield and am very happy with the leather they have been shipping. Some very nice oil tan that is very good price and gets here in 2 days. For veg tan I have mostly been ordering direct from W&C, but am thinking about trying Herman Oak to compare with the W&C.

-

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks Brian, I think the size you have will be fine. I normally don’t like to print larger than @220mm in any direction to allow room for brim/skirt around the outside. The case I just made had fringe from 6” out to 12” - I cut the leather at an angle and then start cutting the fringe. Like Dikman suggested, maybe cut and then move the template further down to continue for longer fringe? I think this might be difficult to do and keep cuts aligned with the slots in the template, but worth a try. Worst case, I go back to using my straightedge, which really doesn’t take that long once you get going. Gary -

Hi Kristina - welcome to the forum. That’s an interesting niche market product line and looks to be very high quality! Gary

-

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

That’s a cool fringe guide Bob - thanks for sharing! thanks Brian - that looks great! If it isn’t too much trouble, I would love to have the stl file. My printer bed is 250 x 250mm, so your template size should be fine. What percentage fill are you using? I only use a rotary cutter when cutting soft temper leather up to 4-5 oz. Seems even with a sharp razor knife that thin leather tends to bunch up, but the rotary cutter rolls right through it! Gary -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I just lay out a piece of leather and take a straight edge and rotary cutter and cut one at a time. Takes me 15-20 minutes to cut two pieces of fringe 10” wide. -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

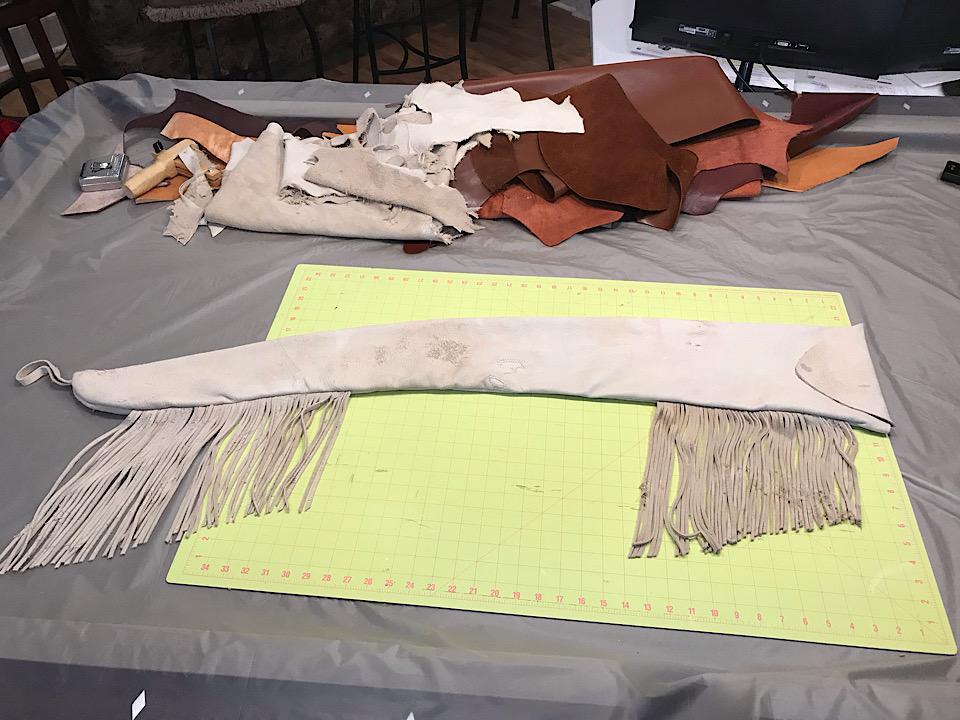

Made another case today using economy grade elk - had to trim a lot of loose skin and patch a few holes. I think for large projects I will stick with the better grade hides from now on. Still have to install hoeprn button and tie. Anybody have a good source in the USA for elk or deer horn to make buttons? -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks - appreciate your comments! -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

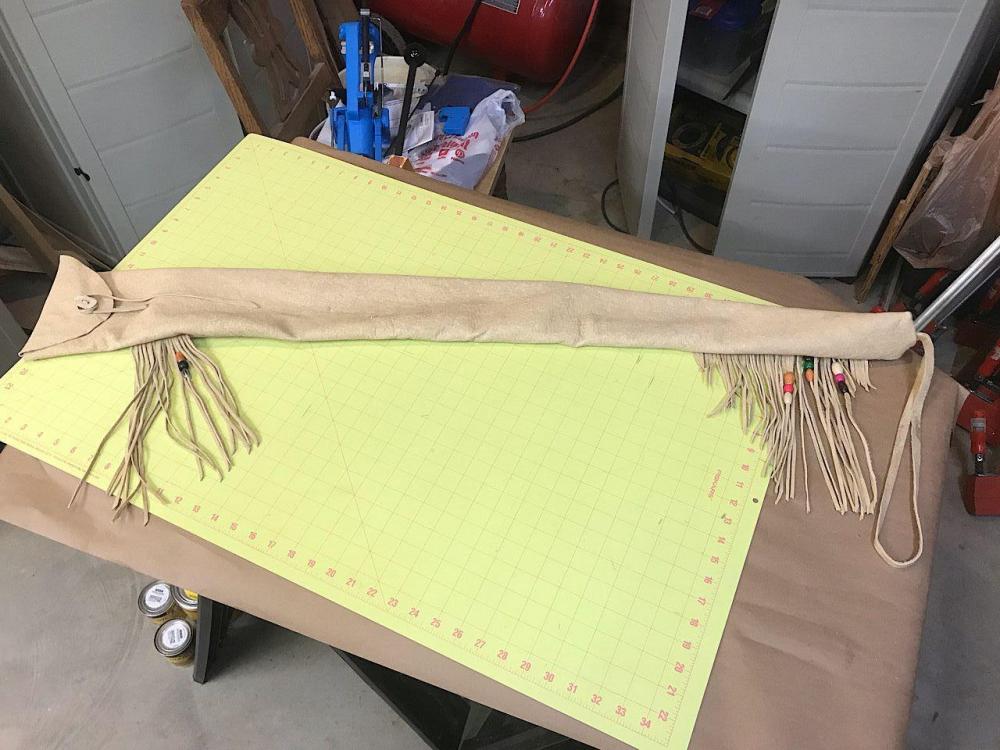

Made another rifle case this afternoon using a piece of 3-4 oz Italian cowhide. Took me a little less than 2 hours start to finish. -

Custom Laptop Bag

garypl replied to AndyL1's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Really nice case! Looks like you airbrushed the dark edges? Gary -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

I bought one of each from Springfield and the price difference was $1.00/ft. I would recommend only buying the craftsman grade unless you had a lot of very small projects, as there were more holes and ragged leather in the economy grade ( as Chuck mentioned above, the craftsman grade also had holes, but not so bad as economy. I can make two sheaths from a 20 ft section of hide.) Gary -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks - I will take a look when I order more elk! Gary -

Elk Hide Gun Sheath

garypl replied to garypl's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Thanks - where did you get the elk hide? The hides I bought were inexpensive but had a lot of loose, ragged skin on flesh side. -

Made a gun sheath for a customer out of smoked elk hide from Springfield Leather. 45" long. First time I have worked with elk and it is soft temper, so not so easy to cut! Seems very sturdy and he liked how it turned out.

-

My take on a Western Gun Rig

garypl replied to KrisQ's topic in Gun Holsters, Rifle Slings and Knife Sheathes

Kris, that is a beautiful rig you made! Look forward to seeing more of your work. Gary -

Here is a guide for 1.25" belts and I am printing from a new file for 1.5" today to make sure it works. 1.25 Belt stamp Guide.stl I was able to go into the original file, ungroup the stamp center opening from the rest of the guide, expand the guide to 1.5" and regroup the center opening - looks like it should work and I will post the 1.5" file tomorrow after I test it. Gary

-

Will do Richard - thanks!

-

I printed a 1-1/4” guide and tested it - will post file here tomorrow. Will do 1-1/5” next. Brian, I don’t use Curra, but it’s easy enough to expand the size - I want to keep the center opening the same size to fit the 1/2” stamps. I’m not savvy enough yet to probably do this the easy way!

-

I’ve been using the Giardini edge paints for about a year or more and I really like them. I posted some test results here comparing them to Angelus and Edge Coat and I think the Giardini paints are better wearing. They are pricy when you have to ship them from Italy, but they sometimes have specials. You can also buy them from Campbell Randall here in the US, but last time I bought from them they had limited colors and I think they were only offering them in the 1 liter size - this may have changed by now. Gary