-

Posts

37 -

Joined

-

Last visited

About Trevor Baret

- Birthday 10/19/1953

Profile Information

-

Gender

Male

-

Location

. Blue Mountains, NSW, Australia ............................

-

Interests

. Anything to do with leather, leatherwork and leather sewing machines ...........................

LW Info

-

Leatherwork Specialty

. Learning new stuff by making plenty of mistakes ...........................

-

Interested in learning about

. Whips and whip making; Lacework and Braiding; Making bags, satchels and tools storage; Use and repair of industrial leather sewing machines;

Recent Profile Visitors

3,237 profile views

Trevor Baret's Achievements

Member (2/4)

-

What year and where was my Singer 111W-153 built?

Trevor Baret replied to Sugarkryptonite's topic in Leather Sewing Machines

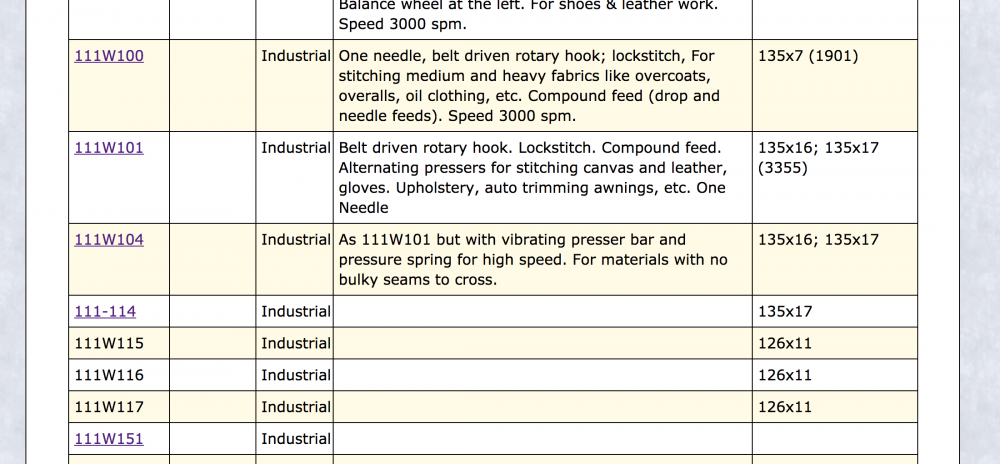

The model number is not the W The model number is 110W-..... Go here - http://ismacs.net/singer_sewing_machine_company/model-list/classes-100-199.html Scroll down till you see 111W and you will see a variety of model numbers - see the attached screenshoy -

What year and where was my Singer 111W-153 built?

Trevor Baret replied to Sugarkryptonite's topic in Leather Sewing Machines

To find the age of your machine, find its serial number, and look it up here - http://ismacs.net/singer_sewing_machine_company/serial-numbers/singer-sewing-machine-serial-number-database.html To get some basics about what they were originally designed to do, look up the model numbers here - http://ismacs.net/singer_sewing_machine_company/model-list/classes-100-199.html Hope that helpw. -

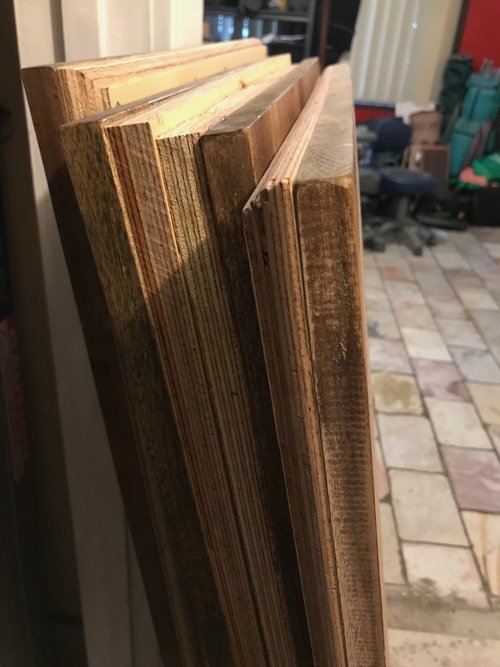

I have started on four table tops. The photos below show what I have so far. I went to the local hardware store. In Australia, this is Bunnings - In USA it would most likely be Home Hardware to get what you want. The beautiful decorative timber table top is precut to size and was one of numerous colours. 3/4" thick and precut to 2' by 4' (Metric 600x1200x20) (It also comes in other sizes) This size is almost exactly the same size as most of my industrial machine tables. I glued and screwed it to 3/4" marine ply for the sake of extra strength and rigidity for the first two. The ply was also precut - about 1/2" longer and wider than the decorative timber. Cut to size first, before attaching. You can see that I have routed the ply on two of the four table tops - I will do the same with the others when they are glued and screwed. Next, I will lay the old table on some butcher paper to mark the size and shape of the hole for the machine. Check that and cut and rout the new table tops - making sure I leave supports for the machines. I will do some minor filling with putty, then sand, stain and coat with polyurethane. All of my machines are Singers (look at the signature file below), and I have great original Singer industrial legs including heavy duty bases for those with motors and a couple of sets of excellent industrial treadle bases in perfect working order. I will select the bases for each machine, attach them to the table tops and mount my machines. looking forward to documenting the entire process. I hope this gives you some inspiration.

-

I thought I would mention this machine going off on ebay today - less than seven hours from the time I write - https://www.ebay.com.au/itm/1946-1-500-Singer-132k6-Sewing-Machine-Leather-Came-Off-WW2-Aircraft-Carrier-/123417296542?_trksid=p2385738.m4383.l4275.c10 It appears to be in good condition, with various parts as well. Everything is there and they say it is in good working order. You could get it for close to $400.00 They say is came off a WW2 Aircraft Carrier - so a bit of history with the machine. If I were in USA, I would buy it just because of the history and the pretty reasonable condition - and the fact that it is a good leather machine. But I am in Australia, where these machines are not common and their prices are high. For me, the current price of this machine is about $560Au. Here, there would be a vigorous bidding war to get this one for anything under three times that price... I don't know what these usually go for in USA, but here, that machine is currently dirt cheap. Then add the story attached to it, and it is a great buy. I hope someone here decides to give this machine a new good home. It deserves to be loved and used. Declaration of interest... I have no interest in the sale of this machine. I do not know the seller, and will receive no royalties when it is sold. I came across it by chance, and thought what a great background.

-

Thank you all for the responses about finding the topic. Go to topic Listings is the simplest for the Pinned Topic - if you know it is pinned. It looks like the Google search is more effective than the search on the site. Thanks especially to Wizcrafts for all of the excellent information in the series of posts under the pinned topic that you link above. Incredibly informative for those new to leather sewing machines.

-

Thanks billybopp, How do I find such a sticky. Searching the title came up with no matches. I have actually read most of that series of posts by Wizcrafts before, but then not been able to find it again. My question also applies to other subjects I want to find - I often get the answer "No Matches" even when I know the exact title of the post...

-

Wizcrafts beat me to the same suggestion... Check the tension of the belt. Too loose and it slips. After a long time of use, the belt becomes polished with wear, and starts slipping. You could try some violin bow rosin (from any musical instrument shop) on the belt to make it "sticky". Hold a piece of rosin against the working surface of the belt and run the machine for 10 seconds or so. If gentle pressure with the rosin stops the belt from moving, then the tension is probably too low. Use a feather light touch (not a pun on the very popular singer domestic machine name) with the rosin so that it rubs gently on the belt. The pressure can be slowly increased as the belt gets "stickier" and the friction softens the rosin.

-

Uwe - that is just a beauty to behold... I have no doubt that it was an engineering challenge - but "simplicity" so often is. I am a big fan of good design, and this is a great example. Thank you for your effort and the great result that you have achieved. I am in Australia, so postage would probably cost more that the article itself... But if you were closer, I would be tempted to buy your flatbed attachment, simply because it is such great design (even though I don't have the Cowboy to attach it to... yet...)

-

gloves fur sewing machine recommendations

Trevor Baret replied to d72hemi's topic in Leather Sewing Machines

Hey - I would buy the Singer, just because it looks great and would go well with my other singer industrials... I don't know anything about sewing fur, so I really can't give you any knowledgeable information about those machines - just my passion for the old Singer machines - both domestic and industrial (see my list below my signature). But looking at the ismacs site - http://ismacs.net/singer_sewing_machine_company/model-list/classes-1-99.html ... it looks like the one you are looking at is the right machine. Just check whether it is single thread or double thread - just so you know what you are getting. 46K26 is capable of double thread - as pictured here - Your photos look like there are two tensioners ready for two threads. Check with the Cowboy suppliers here - they can tell you if they have parts which will fit such a machine. I have my doubts but they might. The standard leather straight stitch machines from Cowboy usually have interchangeable parts with old Singer machines, so they might have some equivalents for the 46. What a great looking machine - now I want one... (even though I don't have any plans to sew fur) Good luck Trevor -

I just weighed mine - 34 Kg. Stood on the scales to weigh myself, then picked up the base and checked the increase. So this is not exact, but pretty close. (Very good quality electronic scales, not cheap spring base things.) You might be able to squeeze it through if they are not too strict on exact weight. Do the couriers actually weigh the product? You can see by the pattern on the sides that this base is early 20th century - before 1920. Hope this info helps.

-

Hey Ron, I am tempted to say keep the Durkopp and send me the Singer. But that might be affected by my self-interest... Like Constabulary, I am a bit of a nut for Singer machines (which is obvious in the list I show below), and I am looking for a 111 to include in my collection. But the cartage from Seattle to Sydney would be more than the cost of finding and buying one in Australia. From what I know (without ever using either of these machines yet) I can only second those comments above.

-

Zipper installation multipurpose guide

Trevor Baret replied to RockyAussie's topic in 3D Printers and Lasers

Fantastic, Brian. Thanks for all of the detail and the .stl file. Will keep watching for further updates... -

Jon, I am coming into this a bit late. Glad things are improving for you - no surprise as the people in this group are amazingly helpful and have incredible and broad knowledge. I will add my two cents worth (and that may be all it is worth). I look at the photo and think along the lines of - "If I had just bought that machine off ebay (or elsewhere), the first thing I would do, even before testing it out, would be to clean it up completely. Having a patina in the surface suits the cosmetic preferences of some (me included in certain circumstances) but having it on the mechanical working parts will have a negative effect on function. After all, we buy these machines to use them so their function needs to come first. So get all the working parts shining so close to new as possible. Oil all moving parts - just a little, don't flood the machine. Then test it out." That's exactly what we do with any of the machines we have bought. Take grateful advantage of offers of pdf manuals - there are plenty available for most machines. And continue to do what you did here - ask questions. Trevor

-

Hey Rocky and Mizzy Darren is in Goulburn NSW - between Canberra and Sydney. Find Darren here https://www.facebook.com/darren.brosowski. He is fantastic with vintage machines in general and Singers in particular. In Aus, you are unlikely to find anyone more knowledgeable. Steve is on the Qld coast - Bundaberg I believe... I think Steve and Darren partner in their Cowboy business. Don't know who is in Queanbeyan, and I wouldn't deal with those I know in Melbourne.