-

Posts

143 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by David Bruce

-

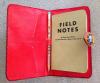

Here's a little case that I just finished. The tooling is based off of an old botanical illustration. I used calfskin for the lining this time around and applied the dye and tankote with an airbrush. I had planned to dye the lilies different colors but thought it looked nice as is. Let me know what you think.

-

Bones Wallet

David Bruce replied to David Bruce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

The top edge of the pockets are just dyed and tan koted. I like the clean edge that you get with pigskin. -

Just finished this wallet. 3 oz. Hermann Oak shell, pigskin interior, tiger thread. This is my third project and my first stab at figure carving. I drew some baroque style flourishes for the background. Let me know what you think,

-

The Production Of Sheridan Style Mural Process

David Bruce replied to bobocat's topic in Floral and Sheridan Carving

Beautiful work and very inspiring. -

What Sharpeners To Buy...diamond Or Arkansas Stones

David Bruce replied to David Bruce's topic in Leather Tools

It's interesting and frustrating how everyone's opinion on sharpening differs. I have been holding off on sharpening with my Norton oil stone in fear that I would ruin my tools. I think that I will give it a try and if it doesn't do the job I can always get DMT's, etc... -

By "Rep" do you mean from Horween? How much leather do you purchase at a time? I called and emailed Horween's sales reps inquiring about buying direct and no one ever got back to me. I figured that they only deal with large manufacturers. It would be so much more convenient and enjoyable to get it straight from the tannery considering that Its so close by.

-

Tried to delete my post but not sure how

-

What would you consider to be a good price for a used Dake 1 1/2 ton press in decent condition?

- 8 replies

-

- arbor press

- bench tools

-

(and 1 more)

Tagged with:

-

I've found some used Dakes on my local Craigslist. They are still pricey so I will hold off until I get my stamps. According to the Grainger website the Palgren presses are made in China and I just can't stand cheap steel (my personal preference). I'm still getting artwork together and am going to order a sheet of magnesium stamps from Phillips Engraving. I watched a video on youtube by Ian Atkinson where he uses them with good results.

- 8 replies

-

- arbor press

- bench tools

-

(and 1 more)

Tagged with:

-

10 hours of lacing! It looks great but, damn! I hope you charge a pretty penny for your seats. I'm going to make a cafe-style seat for my CB550 later in the spring, might have to scrap the lace idea though.

-

Not Really Showing Off

David Bruce replied to David Bruce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Also, I know that black kills detail but it's what my friend wants. I was thinking of maybe trying the starbust method like fender guitar uses with black and grey but I don't have an airbrush. -

Not Really Showing Off

David Bruce replied to David Bruce's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Thanks for your replies on this. I was able to find a couple of threads that covered this topic. I'm going to try and dye the wallet black except for this bones graphic then apply RST over everything. Once that dries I will paint the skull and fingers with a mix of white and ocre acrylic (I have some Tamiya model paint that should do the trick). I'll see how that looks and if it's still not satisfactory, I'll apply some antique on top and post the result. -

I wasn't sure where to post this but maybe someone here will chime in. I just carved this test piece to see if I could pull this off for a wallet that I am giving to a friend. The plan is to do some baroque style scroll work for background then dye the wallet black. I would like to dye the skull white and would like to know how you guys get that antique/realistic bone color on your work.

-

Día De Los Muertos Biker Wallet

David Bruce replied to neke's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

Very nice! I am working on something kind of similar at the moment. It's cool seeing people's different takes on things. -

Awesome work! There is so much inspiration on this forum. I haven't tried lacing/braiding yet. How long does it take you to lace a seat?

-

Thanks for the info. I just did a quick search on Palgren and some say that they have moved most of their manufacturing overseas. I cant's find anything definitive but see that they were bought out last year by some co. named CH Hanson. So, who knows...I am going to look around for a Dake and see what happens. Thanks again!

- 8 replies

-

- arbor press

- bench tools

-

(and 1 more)

Tagged with:

-

What Sharpeners To Buy...diamond Or Arkansas Stones

David Bruce replied to David Bruce's topic in Leather Tools

Thanks for the tips. Electrathon, I've read about the DMT plates and I actually looked at the Leather Wranglers site ( I would love to try out their swivel knives). Why do you prefer the DMT plates? Which are best to sharpen and maintain awls and swivel blades? I was thinking about getting a 3-pice boxed set of Arkansas Stones (coarse, medium and fine). I want to get whatever system/combo will give me the sharpest tools. -

I am looking for a small arbor press to use for hot stamping on small items. Most of the leather will be 2-4oz range. I was going to get the 1 ton Harbor Freight unit but reminded myself how I always regret buying cheap tools. I would appreciate it if someone could point me to a good US made 1-2 ton manual press that doesn't cost a fortune.

- 8 replies

-

- arbor press

- bench tools

-

(and 1 more)

Tagged with:

-

I recently got into leatherworking and need some recommendations on what sharpeners are best for keeping my swivel knives and awls sharp. I have read differing opinions and would like to know what others use. I currently have a Norton double sided oil-stone and a home made strop.

-

What Size Bevelers Should I Use For This?

David Bruce replied to David Bruce's topic in How Do I Do That?

Electrathon, thanks for chiming in. I figured that I would need at least a few more bevelers. Do you have recommendations for small sizes? I am thinking of ordering some from Barry King. Thanks again! -

I am starting my second tooled wallet and realized after I started carving it that my beveler is probably not going to work. I would hate to ruin this since it's on Hermann Oak. I only have one beveler that was part of a set from Springfield. It's labeled US Stamps and is a size BW16. Any suggestions?

-

I don't think that you are being too ambitious. I just started working with leather and went ahead and made one of these Japanese style wallets for my first project. It was a challenge and I did tool a few flowers on some scrap to get a feel for it. The biggest problem that I encountered was that the outer shell's shape distorted when I tooled it. I have since learned that you can tape the back of your leather before tooling to avoid this. The inside was also difficult but do-able, just be sure to follow electrathon's advice and do a paper mock-up first. If you do a lined interior that goes over the fold you have to account for stretch. Take a look at what I did (it was finished a couple of weeks ago). http://leatherworker.net/forum/index.php?showtopic=53398 If you are patient you can totally do it...Good luck!

-

For anyone in the Chicago area looking for a granite slab checkout factory direct in Bensenville out by O'Hare. I just picked up two pieces of granite ( 24"x18"x1.25" & 48"x32"x1.25") for free. They just toss remnants out back on palettes and are happy to have people haul it away since they pay to have it removed.