-

Posts

86 -

Joined

-

Last visited

Profile Information

-

Gender

Female

-

Location

Calif

-

Interests

Arts and crafts of all kinds, books, family, country life.

LW Info

-

How did you find leatherworker.net?

google

Recent Profile Visitors

6,835 profile views

Willie0's Achievements

Member (2/4)

-

I might add that this one did not have the oil bath pan. Also it has the adjustable step knob on the top of the machine. The difference in the amount of bobbin thread this machine holds compared to the 111W is wonderful.

-

Just to bring closure to this thread, I bought a 1508 H-10 from Artisan. They were the closest dealer to me and were very detailed in answering my questions. The machine is just what I wanted.

-

First let me say that I am so appreciative of the help from the very knowledgeable people here. I am ready to order my machine now, and am leaning heavily toward the Juki 1508 NS, but would feel better with a second opinion. At the lightest, it would need to be able to sew 2 layers of denim or upholstery fabric with a 138 or 92 thread. At the heaviest, up to 1/2 inch at the seam intersections of upholstery leather, still with 138 thread. I notice the 1508 has a much larger needle hole than the 111w155, and wonder if that is a limiting factor. The 1508H is in my budget range if it can handle the desired fabrics. The outer shell is an example of the lightest fabric to be sewn.

-

I set up all my machines pretty much the same. I use magnets to hold scissors, feet and tools. I made "oil holsters" to attach to the thread stands, so the oil bottle is upright and close at hand. On the white Juki, I sewed magnets between two pieces of leather to hold my favorite feet. Most machines have a designated needle holder, so I can tell at a glance what needle is in the machine. All have a thread catcher bag, the Cobra's is held on with magnets. The magnetic dish from Harbor Freight is good to keep on top of machines for feet or tools. Also, I keep a variety of test materials at the back of each machine so I don't try out a new setup on my good piece.

-

I am following this conversation as I would like to upgrade from a 111w155 to another flatbed machine with reverse. I also have a Juki 8700 and a Class 4. I sew mainly upholstery canvas and chrome tan leather with the 111w (138 thread), but am starting to overtax it with too many layers, so it will skip stitches when doing so. The 111w is good because it is very versatile- I can make denim jeans, a leather jacket or fix military canvas surplus. The machines that look like the most promising replacements are the Class 20, the 1508 and the Thor 1541s GC which has a speed reducer. Would the 1508 or the Class 20 be too much for the regular upholstery fabric/denim? Thank you for any insights or responses

-

111w155s everywhere .....cheapest ever?

Willie0 replied to DonInReno's topic in Leather Sewing Machines

They always seem to be around $800 here in central CA. I lucked out and got a working one years ago for $250 but that seemed like a fluke. -

So the 1508 sews the same sorts of materials as the 111? I don't need one that sews thicker material, so much as it is quite happy with the 138 thread, and uses the same feet.

-

I truly love this tough old machine and have sewn lots of canvas, denim and upholstery leather with it. I have lots of feet and a binder set up for it. I use 138 thread, but would like to use thinner thread for some projects, like leather jackets. I have a Cobra 4 and a Juki 8700 for bigger and smaller projects. However, the Singer is finicky for changing any settings, and I sure get envious thinking about machines with reverse. My question is, what new machine would make a close replacement, that could use the same feet? The 1541s looks good to me, but I see it maxes out with 138, and I am leery of running a machine at a maximum parameter.

-

Looking for Glove Pattern/ How-To???

Willie0 replied to GuitarLeatherDopeFiend's topic in Patterns and Templates

Try searching sewing pattern websites. McCalls, Simplicity, Butterick and Vogue are available at Joann's fabrics and Hobby Lobby. Vogue 8311 has some nice gloves. -

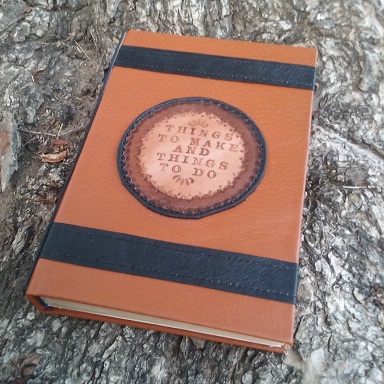

Instructable's website has some nice tutorials. They aren't necessarily traditional, but get the job done. https://www.instructables.com/id/Bind-a-Book-in-Tooled-Leather/ https://www.instructables.com/id/From-Paperback-to-Leather-Bound/ I have made a couple of books by cheating and attaching the tooled leather onto some that is thinner and more flexible.

-

Cobra Class 4 - Adjusting to sew thicker materials

Willie0 replied to luckyclover's topic in Leather Sewing Machines

Worked like a charm! -

Cobra Class 4 - Adjusting to sew thicker materials

Willie0 replied to luckyclover's topic in Leather Sewing Machines

Thank you so much Wizcrafts. I will try this in the morning. -

Cobra Class 4 - Adjusting to sew thicker materials

Willie0 replied to luckyclover's topic in Leather Sewing Machines

I was wondering about this issue as well. My foot will not rise above 9/16th inches. However, the machine came with a "test stitching" block of leather 3/4 inches thick, which it will not come close to fitting under the feet now. -

If it is in a place no one sees or for a utility piece (like canvas repair) #2. If looks matter I leave the tails long and use needles.