Evo160K

Contributing Member-

Posts

497 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Evo160K

-

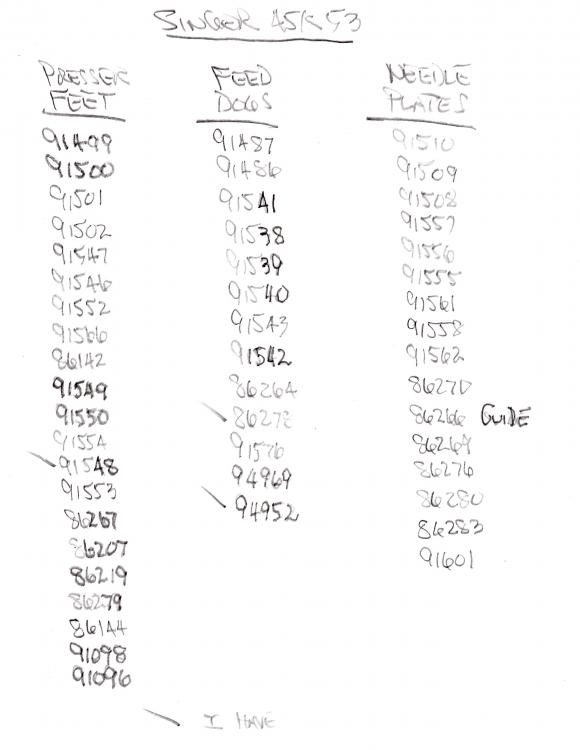

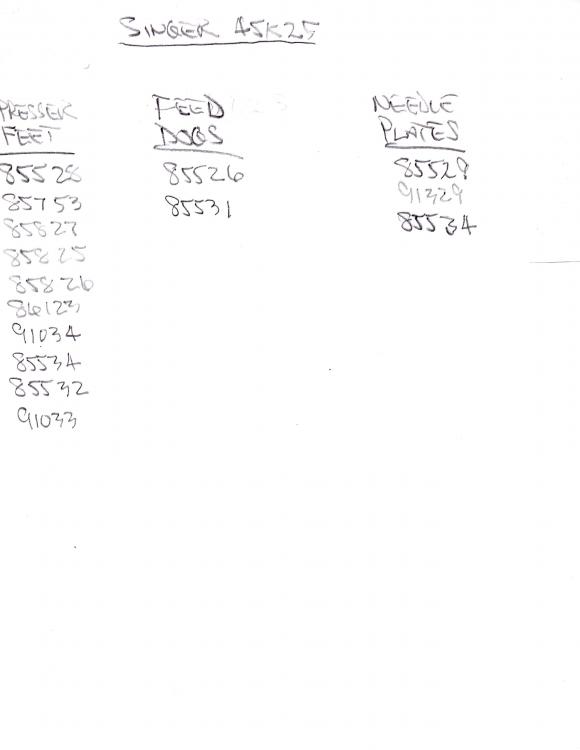

Trox, Good suggestion, thank you. Here are two lists of parts that I'd like to have.......one for Singer 45K25 and one for Singer 45K53. They're the lists I gave to Ralph's Industrial to check. I don't have pictures, but since I'm only wanting original Simanco parts, the Simanco part numbers should be adequate. If anyone has a part marked Simanco, it's easy enough to check the lists for that number. Thanks again, Trox.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Matt S Here's a parts list with pictures for the K1, K5 and K11. Maybe it will have some answers. http://hensewfiles.com/PDFs/SINGER 45K5.pdf Looks like the K1 and K5 are identical with the exception of the roller foot, as you said. Since they share the same presser bar, the usual feet for a K1 or K25 (cylinder arm) will fit on the presser bar. The roller foot does clamp around the presser bar. Others more familiar with using the machines will need to tell you if you can sew with a regular foot on a K5. I suspect it will, because the regular foot sews in place of the roller foot on my K25. I have an extra roller foot and wax pot if you need them, they're not Simanco.

-

Just bought a Singer 45K52, Did I make the right choice?

Evo160K replied to warhorse1700's topic in Leather Sewing Machines

Warhorse1700' Yes, those wax pots do look great, and they do complete the machine. I looked for six months for one to finish my Singer 45K25,......had feelers out around the world. Then, thanks to some really good people here on LW, that I had made commitments to, I ended up with three wax pots. The second is on the Singer 45K53 machine in the picture above......I have the third. It has no identifying name or number on it.......it appears identical to a Singer. Attached are a couple of pictures, PM if you're interested or want more pictures: That tension release assembly is attached to the top of the presser foot bar. Take a look at the face picture above, the needle bar is the one to the right. If need be, you could extend the length of your presser bar by welding a piece on to the top. Here's a link to a company that sells a complete Singer 45K53 parts list (and others I assume) with scaled drawings. https://proleptic.net/ You'll need to contact them, because that parts list doesn't show on their website. Without those drawings, I would never have been able to make the parts that I did.- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

Just bought a Singer 45K52, Did I make the right choice?

Evo160K replied to warhorse1700's topic in Leather Sewing Machines

Warhorse 1700, Here are several pictures of the 45K53 that member Jimi mentioned I was restoring. The 53 subclass feeds from the top and bottom independent of one another, either can feed faster or slower than the other, and either can be shut down to make it top feed or bottom feed only. I think this type of feed may be advantages when sewing tubular goods or goods that tend to slip on one another. Others on LW may know for sure. The knob shown by the upper red arrow adjusts the stitch length of the needle thread by moving the knob/fulcrum shown by the middle arrow up and down, Up is the longest stitch, down the shortest. The knob/fulcrum at the middle arrow can be tightened down to prevent the stitch length from moving unintentionally. The screw and locking thumb nut shown by the lower red arrow move the feeding presser foot with respect to the needle. As far as I can tell, it doesn't change stitch length at all, it only positions where the presser foot comes down on the goods. This may be to insure the points on the bottom of presser feet, such as yours, drop exactly into the needle holes. Sure would appreciate it if some of you good people familiar with this type of feed would comment. This next two pictures show the tension release bracket with hook and the thread retainer bracket that I had to fabricate thanks in great measure to a lot of guidance from Jimi. Thank you Jimi. The machine is amazing, it's taken a lot of fabrication, but it's running perfectly, and I've enjoyed every minute working on it. It'll get paint once the 45K25 I'm redoing is completed.. Here's a picture of the front. and a couple of pictures of the lifting mechanism. The lift is adjustable. And the face- 21 replies

-

- singer 45k52

- singer

-

(and 2 more)

Tagged with:

-

Thanks Chuck, good to know.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Thanks for the link, Mark. I'll contact them and see what else they have.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Secondcrk No, but I will. Thank you for the lead.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

You people are awesome. Thank you.

- 18 replies

-

Thank you good people one and all.

- 18 replies

-

Here's a picture of the result of a spot test on my Singer 45K21 of Rust-Oleum's 255447 Aircraft Remover. I was skeptical when I read the description, but because there were many glowing user comments, I bought a gallon. It worked (for this test at least) just as the instructions stated. I applied the gel with a natural bristle paint brush, left it on for 10 minutes exactly and wiped it off easily with a putty knife. I was shocked!

-

Thanks Singermania, that helps. Thank you.

- 18 replies

-

Is there a rule of thumb on a Singer 45 for determining when a rubber v-belt is adjusted properly? A search of this forum found nothing. Thank you.

- 18 replies

-

stickandtin , Regarding the Chinese manual, language became a huge problem when I started restoring my Claes machine, most every manual I found was written in German. Google Translate was extremely helpful, even though in some languages (like German) words can have several translations, in such a case you choose one which is most relevant. Here's the link I use.: https://translate.google.com/#de/en/lager buchse When you don't know the source of the language you want translated, you ask the program to identify it. It's pretty cool imho.

-

What is the best type and quality of leather for motorcycle saddlebags, the straps in particular. The original set of Harley-Davidson leather bags and straps lasted over 20 years (250+ thousand miles), but the replacement set of straps that were ordered from a leather shop haven't lasted two years........they're dry and cracked. The straps are pulled taunt from time to time, and the leather is cleaned and treated frequently with H-D products, same as always. Thank you very much for your input.

-

Yetibelle, Just the original Simanco that came with the machines plus some non-singer that I found online. I've had to makes one or two other versions, but of course those are not marked Simanco. I would like to have a couple of spares, "just in case" and perhaps other styles for other types of work. Thank you for asking.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

These parts are turning out to be really difficult to find. Anyone have any leads or know where I might find one or two? Thanks all.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Hi Constabulary, Thought you might be interested to know, the local gasket distributor cut some clutch discs for me today....two out of cork and two out of 16 oz veg tan leather. Based upon your suggestion, I installed a leather disc with the split side out, no cement (if it failed to work)......it worked really well, even had good startup control. I'll leave it in to see what happens going forward. Regards -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Constabulary, when I first looked at the clutch material I thought it was leather, I even sanded on it and picked at it to see, it just didn't look like cork. I'm about 90% sure it is leather, in any case, it's working well again. Thanks for the suggestion. Something else I stumbled onto while trying to adjust the "feel/grab" of the clutch was by preloading the return spring about 25 mm, it gave me great feel and control at startup and run. It's sort of like how some people suggest putting a tennis ball or piece of heavy foam under the foot pedal. I did that on the Claes pedal, however I find preloading the spring if you have it is much better. Regards -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Mikesc, Thank you very much for your interest. As it happened, a couple of days ago I put clutch material, cork into the LW search and found gottaknow's comment as well as CowboyBob's. Bob said use bearing grease and I can't recall what gottaknow said (senior moment, I guess!!). I tried the blue high speed bearing grease on the old cork and it worked like a champ, And that's after the cork had soaked in the electrolysis stripping tank for three days. I'm going to save the new piece of cork for a backup. -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Glenn, thanks for the information, I really appreciate all of your help. I just ordered a small piece from the local gasket distributor, they didn't even want to charge me for it. Mikesc, thank you also for the heads up. I wouldn't want to make that mistake. -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Thanks Glenn, thank you very much. The stand and reducer clutch are going back together pretty well.......they don't look too bad, I'll post a pic when they're finished. One part that may need replacing is the reducer clutch material, (it's very thin maybe a 1/16"), I believe it's cork. Would anyone know for sure if i's cork and where I might find a replacement. Are there any installation and adjustment instructions for the clutch material? Thank you good people. -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Good suggestion, Glenn, I will. Thank you. What is your preferred brand of black and clear lacquer? -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Thanks Bob -

Would Appreciate Your Advise On Restoring This Singer 45K25

Evo160K replied to Evo160K's topic in Leather Sewing Machines

So after all of this time, I started painting the metal stand the Singer 45K25 sits on and the Singer reducer clutch. I used the electrolysis method mentioned in one of the LW topics to remove the rust and paint........it worked well. Although I took a lot of pictures of everything before disassembling anything, I can't tell from the pictures if the reducer clutch was painted with a gloss black or a semi gloss black. Does anyone know what the correct paint should be on the Singer reducer clutch that's mounted under the stand? Thank you very much. -

How to Determine if a Thread is Bonded Nylon or Bonded Poly?

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Thanks Colt, very much appreciate your input.