Evo160K

Contributing Member-

Posts

497 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Evo160K

-

Singer 45K Treadle Base Parts Information or Parts List

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Jimi, you're awesome, thank you for your kind offer. Look forward to the dimensions. Will you be able to determine the thread details on the support and the fasteners that hold it to the base? That plate looks to be close to 10-12 mm thick? Glad you got your PC fixed, they're such a mystery to me, I call them and electricity "Black Art". Best regards, Al -

Singer 45K Treadle Base Parts Information or Parts List

Evo160K replied to Evo160K's topic in Leather Sewing Machines

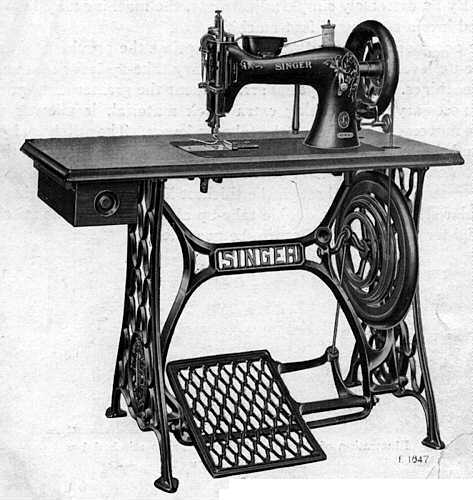

Just to clear this up for me. You have the 45K treadle now, just like in the picture but it is missing that support? Don't have it yet, the base (only) as in the picture is in transit to me. It may need the pieces we've been discussing, there's some confusion about that, so I may have to find or make them, and I want to know about the dimensions. Do you sew veg tan with yours? -

Singer 45K Treadle Base Parts Information or Parts List

Evo160K replied to Evo160K's topic in Leather Sewing Machines

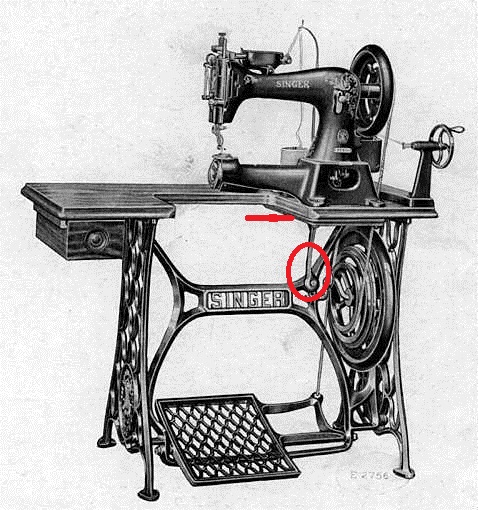

Hi Matt, The plate indicated by the arrow and the vertical support/bolt in the circle may be missing. If so, I'll need to find them or fabricate them. Usually the illustrated Singer parts list are drawn to scale,....helpful for fabrication. That's why I'd like to find a parts list or get the measurements from someone with this type of base. Your base looks to have different supports. On a side note, how thick of veg tan can you comfortably sew through with your treadle? That treadle flywheel looks massive. Thanks for your interest. -

Singer 45K Treadle Base Parts Information or Parts List

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Hi Yetibelle, Base is on the way. It may need a couple of upper support pieces in which case some fabrication will be required. Hoping to find a parts list with pictures in order to get the correct scale for the part. -

This is in the Smithsonian, might be a long shot. Guide to the United Shoe Machinery Corporation Records http://amhistory.si.edu/archives/AC0277.pdf Constabulary is correct, contact Pilgrim, they show the ORL-O on their website and say they have parts. http://www.pilgrimshoemachine.com/sewing_machine.html

-

That's impressive!! Looks outstanding to me. As a side bar Uwe, the 45K shuttle came in today.....fast and beautifully packed......very professional. Thank you

-

Any one know where I might find some of these parts? Thanks very much.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

Anyone Tried this Speed Reducer?

Evo160K replied to KeithHideWorks's topic in Leather Sewing Machines

Keith, You might want to check the article and video in the link below to see if his method will work on your servo. Note in his comments that begin about 2:49 into the video, he found by setting the speed range to "0" on his Enduro servo, he had far more torque. I found that also to be the case on my Consew CS1000. http://www.swflholsters.com/358/sewing-servo-motor-diy-smoother-speed-control-mod-paper-gradient/ -

Singer 29k171 "Another journey to the unknown"

Evo160K replied to jimi's topic in Leather Sewing Machines

Happy New Year all! Hi Jimi, nice looking machine. It's amazing the original paint wasn't damaged by the solvent....well done! darning video. https://www.youtube.com/watch?v=TfHJ6Fr43Ys -

Cast Iron Again - Pearson & Bennion / BUSMC A1

Evo160K replied to Constabulary's topic in Leather Sewing Machines

Sure looks good to me, you cleaned it up well. I just repaired a similar chip on my 45K25 wheel. The welder filled in the chip with a blob of nickel I believe he said he used, he buried the wheel in sand while it was cooling. I used a Dremel tool with double abrasive wheels to shape it. It turned out well, hardly noticeable. -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Uwe, Jimi, Thank you. Here's the Smithsonian link to the full brochure containing the japanning description, it's similar to the Kilbowie movie to some extent. http://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/SIL/0074/imagepages/image1.htm And fyi here's the Smithsonian link to all (?) of the Singer literature: http://www.sil.si.edu/DigitalCollections/Trade-Literature/Sewing-Machines/CF/single-record.cfm?AuthorizedCompany=Singer Manufacturing Company Bad News!! The first test piece, the one shown above, recently developed micro, cross hatched shaped, fractures throughout. They're easily felt with the fingernail. A friend who is a material failure analysis engineer with Orbital Sciences Corp (think: rockets) said he's sure the three coats were too thick and curing at differential rates creating stress cracks. The three coats were each thicker than was suggested in most of the literature I read. I knew that when they were applied, but must say it's surprising the fractures took so long to develop. The plan is to strip and re-do the piece with lighter coats......to be continued. -

Still looking. They're difficult to find.

- 29 replies

-

- singer 45 throat plate

- singer 45 needle plate

- (and 2 more)

-

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

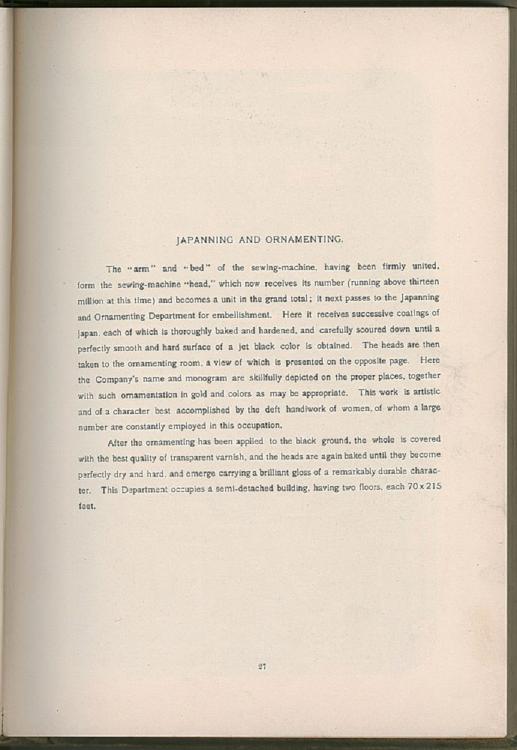

For those who are interested in how Singer applied japanning, you might find the attached page from a Singer brochure found in the Smithsonian Libraries educational. TinkerTailor was on the right track when he mentioned coating over the decals. -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Yetibelle, Thanks for the compliment, but it's quite a bit away from perfect. Once you have your japan, brushing it on is easy, I suspect you could apply each coat on the whole machine in 40 minutes or less. Each coat is supposed to dry over night, and oven curing each coat then takes about 5 hours, so you're looking at 15 hours or so over about 3 days. If you want a quick over view, read the fist red link in my post from Sunday at 3:08. "Now dip the whole machine!" That would be ideal, but I think it would run into about $200-$300 worth of material. -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Darren, Your comment brings up an interesting question about the restoration. Once Singer applied the decorations/decals like in the video Uwe posted above, were they clear coated then "polished" or not? Do you feel the edge of the decals on the industrial machines? You can hardly feel the decals on my wife's K28. -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

MADMAX22, Haven't buffed anything yet. Are you using the polishing compound on the japan or on the unpainted parts? What color compound and what type of buffing wheel do you use? Interesting you mention that brown residue. I just bought an Engine Cleaning Gun Solvent Air Sprayer Degreaser Siphon Tool to attach to the compressor. I'm planning to increase the pressure to help knock off that residue. I'm going to use paint thinner and spray it inside the machine, the thinner shouldn't cause rust like a water based product would. Haven't tried it yet, but it sure looks substantial......certainly was priced right. http://www.ebay.com/itm/302035588980?_trksid=p2057872.m2749.l2649&ssPageName=STRK%3AMEBIDX%3AIT -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

You are all most welcome. Hope someone can come up with the right recipe for sewing machines, seems everyone has their own idea about how to do it, and most of the recipes are for woodworking planes. Seems the planes have less gloss though than the sewing machines, that may or may not be better, depending upon your application. TinkerTailor, that's a great suggestion, I'll give it a try. Thank you. Jimi - why is the foot lift lever on your beautiful machine a lighter color? Second question (I'm full of questions), did you tell me once you put a light coat of shellac on your machine? -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Japanning Black japanning was commonly used 100 years ago on sewing machines, phonographs, iron bedsteads, Stanley planes, other ironwork and of course all Ford model T automobiles until about 1924. It’s a fascinating process, I think you’ll enjoy it. The short version is: add turpentine, boiled linseed oil and asphaltum together. Paint it on. Bake it. Done. First a disclaimer of sorts: recall this humble writer is new to sewing machines, sewing and japanning for sure, so take what is said here lightly. I’ve read probably 25 different articles, watched maybe 20 videos and japanned 3-4 test pieces, none of which look good enough to be compared to an original japan finish. Actually my only problem has been pinpoint air bubbles so far, maybe the brush bristles are too fine and trapping air. The picture above shows my best result to date. I would suggest you read the articles below, watch the videos and run your own tests. There’s even a mesmerizing four part video on making an oriental lacquer brush. You’ll find a lot more material on the internet, of course, if you want to do additional research. The formula and process explained in the first red link below is generally what I followed; be sure to read the questions/comments at the end of the article, one I asked, it explains my complete recipe and process. My test sample, Senefelder's Liquid Asphaltum, came from Graphic Chemical & Ink Company, https://www.graphicchemical.com/shopdisplayproducts.asp?Search=Yes&sppp=25 . I thinned it a bit with turpentine and added about 10-12% by volume of boiled linseed oil (BLO). The BLO makes the finish hard and gives it a gloss. Some use spar varnish instead of BLO. I used the electric oven in our kitchen for curing. The body is too large to fit, so I’ll have to either cold cure it over 30 days, take it to a commercial oven like a powder coater or build an oven out of a 55 gallon steel drum. There’s a link below for building a diy electric oven for those who are so inclined. I believe 3-4 electric heat lamps will reach well over 450 deg F., and can be used in place of ceramic heaters. Liberty On The Hudson, the company in the second red link, offers a ready made Black Japanning Asphaltum paint that is to be cold cured only; I have a quart on order (it’s out of stock until some time in January). I’m not sure what I’m going to do about the head. Well hopefully that’s a start on japanning. Ask any questions you like. Recall, I’m learning as well, so let’s learn together. https://www.youtube.com/watch?v=6WAI0sC4tJc&feature=youtu.be (click on “show more” for this persons process) https://www.youtube.com/watch?v=k-1kxGqmcp0 http://lumberjocks.com/JayT/blog/32704#comment-3549554 http://ismacs.net/sewing_machine_articles/japanning.html http://www.homediystuff.com/building-a-diy-oven-from-filing-cabinet/ http://libertyonthehudson.com/pontypool.html http://www.micaprintmaking.com/wp-content/uploads/msds/graphic_liquid_asphaltum.pdf https://www.youtube.com/watch?v=bsbQAFQzulQ http://www.woodcentral.com/cgi-bin/readarticle.pl?dir=handtools&file=articles_117.shtml https://books.google.com/books?id=L2MJAAAAIAAJ&pg=PA20&lpg=PA20&dq=how+to+make+a+japanning+stove&source=bl&ots=N26USd-E7d&sig=VGxlA0p6yquQgfHto4WSrKDMM1Y&hl=en&sa=X&ved=0ahUKEwjjwfLKmNfPAhVEgx4KHWDYALkQ6AEIQzAG#v=onepage&q=how%20to%20make%20a%20japanning%20stove&f=false https://en.wikipedia.org/wiki/Pontypool_japan http://www.mtfca.com/encyclo/P-R.htm#paint1 Unless you want to get into the minutia, scroll down to the paragraph beginning: The basic oven drying paint for the Model T was what historical sources call “Japan Black”. http://www.cranialstorage.com/Wood/japanning.html -

First Try at Japanning On a Restoration Project

Evo160K replied to Evo160K's topic in Leather Sewing Machines

Thank you Lady and Gentlemen for your kind comments. You and many of the other fine members on LW continue to inspire and educate me about these remarkable old pieces of history. When one contemplates the significance of the sewing machine to the advancement of mankind, it boggles the mind. My wife has kept me occupied with "honey-do's" and other insignificant (please keep that to yourselves), shopping chores to the point where I haven't been able to type what I did. I will later today or Sunday at the latest, I promise. -

Looks too glossy to me for a Singer 45K25 that was built in 1940, but then, I've never seen a restored 45K or even an original one with decals (mine was sprayed over). Does anyone know how they looked new compared to the test piece? It's no problem to tone down the gloss with a fine polishing compound. Researching japanning has been extremely interesting as well as educational. I like the process a great deal, it brushes on easily (no need for masking tape), it fills the imperfections, $100 in materials will probably do 6-8 machines and it's the authentic finish. It can be stove cured or air cured, depending upon how much time is available. The test piece was stove cured. Your comments and suggestions are welcome.

-

Zapee, Here's a link to the company that eventually acquired Claes. https://translate.google.com/translate?hl=en&sl=de&u=http://www.cl-maschinenbau.de/&prev=search They may have operator and parts manuals for your machine, if you need them.

-

If you're wanting to slow down a digitally controlled servo motor without having to us a speed reducer, you might want to check the video in the first link. It was originally posted in the LW topic, "Getting Control of Your Servo". You can see how well that modification worked on my servo by checking the video I posted in that LW topic. The video in the second link explains how to slow down a digitally controlled servo motor with a needle positioning system. http://www.swflholsters.com/358/sewing-servo-motor-diy-smoother-speed-control-mod-paper-gradient/ http://www.swflholsters.com/434/sewing-servo-needle-positioner-eps-speed-mod/

-

Just beautiful.....you're an inspiration, Folker. Congratulations,

-

Diane, Where you able to get in touch with LW member Singermania? He's in Bundaberg, Queensland and has a huge collection of older industrial machines and parts, which he buys and sells.