jonwatsabaugh

Members-

Posts

117 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by jonwatsabaugh

-

Broken Saddle Horn

jonwatsabaugh replied to charliep's topic in Saddle Identification, Restoration & Repair

If the tree is rawhide covered, the hide can be stripped and all the pieces epoxied and pinned back together. After this opperation I epoxy/fiberglass the stucture and rawhide if desired. On tree repairs such as this it's easier to repair the old as opposed to getting a replacement tree to fit exactly as the original. Also it could be a poorly enough built tree to begin with, in such case a replacement would be neccesary. Wouldn't know though untill it's opened up. I've done this alot on saddles that were actually worth repairing. Like Steve mentioned though, whether replacing or repairing it's an expensive operation. Jon -

Burnishing Edges Of Harness Leather

jonwatsabaugh replied to alb's topic in General Saddlery Discussion

Ann, Conventional methods used for veg tanned leather don't work. I simply drag my harness leather straps through a can of paste saddle soap a couple of times to thoroughly saturate them, work it in with my hands, then wipe off the excess (no need to burnish). If you have used a sharp edger the paste soap does a very nice job of finishing the edges. After the soap dries, you can finish by wiping on a coat of Tan Kote. As an added note I always punch holes and buckle slots after the paste soap to avoid having to clean it out of the holes and slots later. Try this method...I think you will be pleased with the results! Jon -

Mini Horse Saddle Trees

jonwatsabaugh replied to steadybrook's topic in Saddle Supplies, Tools & Trees

As Casey mentioned, I make trees in any scale and style. Full size trees can be scaled down for horses or ponies just right for kids. The little trees in the picture are Casey's. The finished one is fiberglass/epoxy encased. The full sized trees in the background have been epoxy coated and are awaiting rawhide. Jon -

I always make sure the skirts and plugs are bone dry before gluing them up. The skirts should have the blocking and curves set. While applying the plugs, I always bend them into the set skirts to maintain the skirt form. After burnishing in the plugs, I wet the inside edges of such with a spray bottle and blend nicely with a French edger. By gluing the pieces dry, and applying very little moisture to finish, shrinkage should never be an issue. When plugs come loose, they were not done right in the first place IMO. Jon

-

Gary,

Have'nt come across your name in quite some time. I used to keep track of the Colorado Saddle Makers Assoc., and your name always popped up. Anyway, yup I am a tree maker and would be glad to talk to you regarding your saddle tree needs. I don't have a catalog or web site but you could call me and I can give you a list of refferences, pricing, etc. Call day or evening at 515-...

-

This year I finally got to attend the TCAA event in Oklahoma City. Oh, what a time I had! The members' works are inspirational indeed but even more so are the personalities behind their fine art. As busy as their week was, I found them very gracious and personable toward the little guy like me. I finally got to meet Chuck Stormes and he took time out of his busy day to look over a few trees I brought. We had a small crowd gathered around my car passing around trees. Among them were Chuck of course, Cary Schwarz, Pedro Padrini, John Willemsma, Troy West, David Morris, and Alan Bell. David, it certainly was a pleasure to meet and spend time with you, and Alan, I'm sorry I didn't get to visit more. As always, Troy, its good to fellowship with you, my good friend! Next year the seminar emphasis will be directed toward saddle making, so mark your calenders, get your work done, save some bucks and get your hide down to OK City for a good time. You won't regret it ! See y'all next September! Jon

-

Thanks all! Brent, I did'nt have a clue how much this tree would weigh once it was finished, but after selecting some lower density poplar combined with my standard epoxy/fiberglass encasing process, the result was 4 lbs. The saddle without stirrups, with breast collar, and both cinches weghed 27 lbs. She had her own stirrups and I did'nt get to weigh them...just guessing 3 lbs. The leather is standard russet Herman Oak with an extra coat of oil and lots of warm Iowa sun. Steve, Yes, it is an in-skirt rig Bara, I just antiqued the stamping and carving to get the color Denise, I use yellow poplar in all my trees. Down the road I want to try using douglas fir, but right now I just can't get good stuff at anywhere near a reasonable price. The poplar however has many great attributes and I like working with it. Jon

-

Here's one I finished for a local gal a few weeks ago. It sports one of my fiberglass encased trees( 4 lbs.) and 13-15 oz. Herman Oak skirting. With everything hang'in, it weighed in at 30 lbs. Jon

-

Dixie, Keep in mind, if you want to do a resto on this old rig it should have square, pointy skirts and jockeys. If you look at the present skirts and jockeys, it is obvious at some point they have been cut, resulting in the large radius. I've seen a number of old square skirt saddles done like that. Those big old skirts really curl up at the corners after they've been hanging in the barn for 50 years and they ain't gonna flatten back down so alot of folks just whacked em' off and try and get some more use out em'. From what I can tell in the photos, this does indeed appear to be a White River style tree. Neat old piece! Jon

-

Just an update on the lightweight I started last Sunday afternoon. As of Fri.evening, everything was done with the exception of the breast collar. Minus the breast collar, stirrups, and front cinch, it weighed in at 27 lbs. This was still accomplished using 13-15 oz. Herman Oak skirting and my full size round skirt pattern. The skirting was a bit on the light side however. JW, Just like you, I sure like building on these trees...super smooth with all edges well defined. Some makers take exception to glassed trees as you well know...I'll do rawhide or glass, makes no difference to me. Andy, I would like to see one of your glassed trees sometime. What's the lightest tree you've made? Steve, I love to see your work. From what I've gathered, as well as being a fine craftsman you are a very efficient builder as well. Keith, Your work is always very inspiring! Your artistry is to be studied, I always learn from your work. I'll bet that was one proud young feller in that picture! Frank, Thanks much for your input as well! I'll try and get finished pics up before me and the family head out on our road trip out west on Tues! Jon

-

I received an order sometime back from a lady who lives locally that wanted a classic Wade saddle built as lightweight as possible. When I was confronted with the challenge I immediately suggested a fiberglass encased tree. She wasn't to keen on the idea at first, but soon I gained her trust and she agreed, as the weight consideration was very important to her. Granted, it just doesn't seem right to put a glass encased tree in a Wade, but when you are looking for major weight savings without compromising strength, it just makes sense, and man, are they nice to build on! When finished, the tree weighed about 4 lbs. I'm hoping the completed saddle will be under 30 lbs. Just started the saddle today...I'll post the results in about a week. Just curious, what's the lightest saddle any of you out there in Leatherworker land have made? Jon

-

This tree is sold. Thanks for looking. Jon

-

-

I think mine was 8-9 oz. 6-7 oz. would work OK also. Jon

-

Here's a chinaman design I got from Cary Schwarz a few years ago when I was in his shop. I don't know how many I had torn out before he showed me his. You can really crank on this one...tightens up a mulehide or latigo wrap ooooh so tight! Start with a piece of latigo about 36" x 1 1/2". Each loop strand is 3/8" wide. Cut them long enough to suit (about 12") leaving about 4" on the end to sew as shown, twist the loops a quarter turn, skive the edges of the tail and you got one tough choker! Jon

-

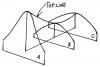

Alan, Your study and analogy is quite interesting. Understandably, everything changes when the horse moves off. My test was conducted at static position, square and level to test my theory of all relative templates. With my results, the different rock templates fit the model differently, and did show the rock template I had chosen as correct. As I had mentioned, this was performed one time and as time permits, I will do further study. Placement of the rock template is the most subjective of the needed measurements, therefore my interest in the relationship of the top line to A,B,C, & R. Jon

-

I to have used the cards in a similar fashion only for my own curiosity...with one difference though. Instead of using the rock cards for gathering data, I use them to test my theory. First I find all three appropriate card profiles, then make a top line template and mark the intersection points. Inverse profile cards are made and fitted together as David has done, building a model. The top profile template positions A,B,&C in the proper position to check to see if I had chosen the proper rock card in the first place. Theoretically this places B in relationship to A & C properly. I've only done this once and everything checked out as my theory intended, but this is not to say this is fool proof in any way. The placement of the cards and establishing the proper planes is somewhat subjective. I know that Dennis and David have given very clear instructions on how to use the system, but I have had a couple of customers give me totally incorrect rock profiles that resulted in a totally incorrect tree. The top line was much easier to determine than the placement of the rock card for them. I wish I had taken pics and archived the info of this process but I did not. I have though, included a drawing of the intended results. Hope this makes sense. Do I even macro-fit on a regular basis? The answer is no. I do these things to try and gain a better understanding of Dennis's system and it's inner-workings and potentials to adapt to my system of construction. I like systems! Jon

-

Butch Cassidy half breed

jonwatsabaugh replied to Steve Brewer's topic in Saddle & Tack Maker Gallery

Man, you've really been knock'n em out lately Steve! Nice lines, very nice finish work! Keep it up Steve, you're puttin out some fine stuff! Jon -

Hello all! I have a Wade tree I built for stock for sale and is available for immediate shipment. The tree pictured is the one for sale. The dimensions are as follows, 15 1/2” seat, 3 3/4”x12” cantle, 4” handhole gullet, 90 degree bars, 4” quadalahara horn cap x 3 1/4” tall. All my rawhide covered trees have partial fiberglass reinforcement on the wood and are completely sealed with a high grade epoxy resin before rawhiding. The rawhide is very nice with nice flat seams. The price is $550 + shipping. If interested or for references, call me at the shop at 515-285-0799. Jon

-

As the old semi-quarter horse, quarter horse, and full quarter horse nomenclature affixed to saddle trees became completely obsolete (I thought it was nonsensical in the first place) so has the idea of designating 90, 93 degree bars etc., become useless in my system of constructing trees. Over the years while studying different trees from some good makers, as Kieth stated, I found that from one maker to the next, there could be a difference of 4 degrees and they all considered these trees to have 90 degree bars. Don't get me wrong, these were all good trees just inconsistent in the front angle. Call me obsessive-compulsive, but this drove me about half nuts(most think I am anyway!). There are two factors, I found, that will contribute to this change in angle. First as Bruce stated, the forward pitch of the fork and secondly, the thickness of the bar at the bottom. To overcome these issues I developed my own system of construction. I call it building from the bottom up. By this I mean that the bars are shaped on the bottom side, fit in a precise jig and then the front and cantle are fit. This is a reverse procedure from most makers methods. Throughout the development stage, careful thought of DL's card system was considered. The result, a very precise and predictable method of tree construction. The legs on my fronts now could be cut anywhere from 93 to 101 degrees depending on a number of factors. Don't let those numbers scare you, the bars are not splayed out to those severe angles. They are cut that way to accommodate a number of factors. The angles are determined by the horse's profile and not any angles cut on the tree parts. My hat is off to Dennis and his tireless work in the development of his system. The cards are very handy, however, if you follow his placement instructions you can make your own patterns for your horse and have what you need for tree fit. I do have a couple of base line standards I start with based on body type. Jon

-

Sounds like Oldtimer is a pretty good source of info. There's another feller on this forum that's also quite knowledgeable in 1800's cowboy gear and a very talented maker. His name is Will Ghormley and I know he has made several Hope rigs. I built several trees for him a couple of years back, one of which was a Hope tree, for a PBS reality series called Texas Ranch House. You may be able to purchase a set of patterns from him for your project. Also, check out his web-site willghornley-maker.com Jon

-

Never seen it on a Wade either, but you sure enough did a super clean job putt'in it all together Andy! Jon

-

I've seen a couple, and I don't think there is a horse on the face of the planet they would fit. Jon

-

Oldtimer, My bars are fixed stationary in my jig, and the cantle and fork are epoxied in place. After the epoxy has set for at least 8 hours, I then run 2" heavy, coated deck screws into the fork and cantle. Jon

-

Andy, I'm glad to know you and Ben are laminating bars also. I've had some makers actually snicker at the fact that I'm doing such, but have always believed it was worth the extra effort. You are also correct in stating that a tree can be out of square even if it is sitting square on a machined surface. This is why I build my trees from the bottom up, not allowing the leg cuts on the front to be the absolute determining factor for position of the bars. I know most makers get along OK building from the top down, the issues I encountered didn't favor absolute precision. Jon