Zandeosaddles

Members-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Blogs

Gallery

Store

Everything posted by Zandeosaddles

-

New forum for 3D printers, engravers and laser cutters

Zandeosaddles replied to Wizcrafts's topic in Leather Sewing Machines

Hi. Nice idea to discuss this 3d tech here. I want to print my carbon saddle trees with 3d carbon filament. Wondering what cost would be for such a machine and the materials. Would lobe inputa from those who know the game. Thanks. -

Hi. I set my machine according to Uwes video on you tube. I also realised the shuttle race spring screws need to be rather loose.Thread binds between shuttle and driver. after 5 years of struggle I finally have it right.

-

Has anyone ever sewn along and the. Check spring snaps in two where the thread runs through it. Must have made a few stitches in its life.

-

- check spring

- seiko copy.

-

(and 1 more)

Tagged with:

-

CB4500 Conversion to treadle or electric

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Darren. Could you post some pics of the heavier wheels? -

My First Leather Hat

Zandeosaddles replied to Bodean's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

My First Leather Hat

Zandeosaddles replied to Bodean's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

I use it sometimes to clean troughs and water the dogs or as a bucket for washing sweat off my hors. Ha ha.lt is super tough. -

My First Leather Hat

Zandeosaddles replied to Bodean's topic in Purses, Wallets, Belts and Miscellaneous Pocket Items

-

CB4500 Conversion to treadle or electric

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Darren. That would give the momentum and toque transfer which my setup lacks for heavier work. Brian. The wheels lock so mo problem. I use a high chair. -

Hi All. I thought I would share my treadle conversion of my machine. We lived off the grid an I decided to convert my machine to work either electrically or with treadle power. Will post an operational video later. Happy sewing. yay now I can post video too.

-

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Hi Uwe. You are my hero! Thanks for this amazing video. My process was correct, but less exact due to my failure to use all the finer tips. I have my feed dog and needle not moving at all on the hook needle height of 5mm. The manual says o to 1 mm? My reverse stitches are better but still loose. When I have time. I will follow your process EXACTLY. I believe it is a very slight timing issue. My machine was also not performing well on thick work. Thanks Brian. Im relieved for now. It is empowering to not be afraid of the beast's insides anymore. -

Consew 206RB-5 backstitch tension problems

Zandeosaddles replied to Indi's topic in Leather Sewing Machines

This sounds very similar to what I experience with my CB 4500 as per my thrraf above.- 2 replies

-

- tension

- leather sewing

-

(and 1 more)

Tagged with:

-

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Hi Brian. This is meticulous work indeed. I have everything triple checked and set up correctly so that all the timing sequences and relative positions are in sync. I realized that the feed dog movement at timing position of needle to hook was out. It is now perfect when alternating the feed between normal max and reverse max ie feed dog stands absolutely still wjen needle is lifted 5.5mm into stroke and hook is in centre of needle So my machine sews at all lengths perfect in forward but somewhat loose and far from perfect in reverse on underside only. At least wprk can proveed again and much is learned although original problem is not solved. I would love to pursue this problem further. My machine has the groove on the upper shaft and is a highhtex and not branded cowboy. -

Amazing knowledge on this forum. I am privileged to have access to all this millennia worth of experience. This is very very helpful ti inderstand the machine better. Happy sewing all

- 22 replies

-

- cobra

- artisan toro

-

(and 6 more)

Tagged with:

-

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Thanks Mikesc. In other words I should judge the setting same ad hook timing. Also, does it matter where the small cam on the right is set when adjusting the one on the left? -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Brian the guide seems to cover some areas better than the others. I want to ask. Should I loosen the lower timing adjustment screw as well when setting the eccentric cam. also Is it the eccentric cam which determines the relationship between needle bar height and hook position? -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

I will definitely check it in the morning. Crunch time now. Thanks for sharing. -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

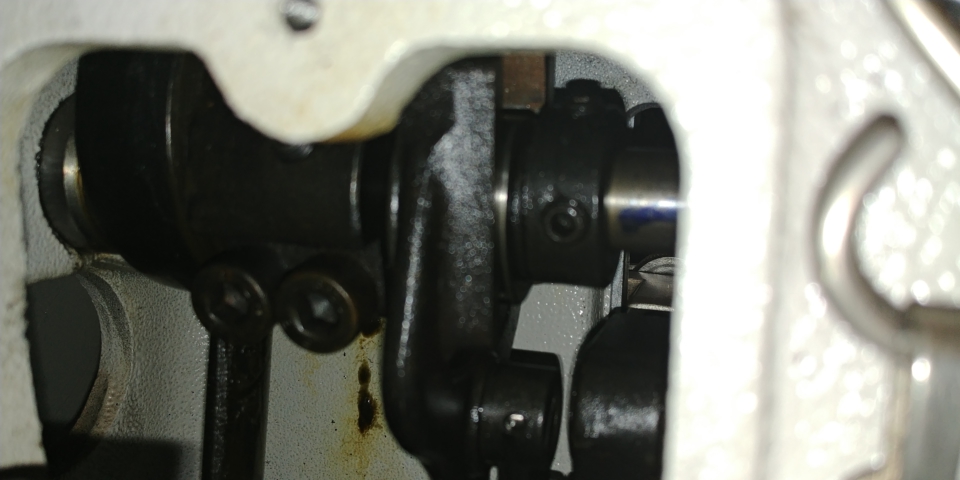

Here are the parts in question. I dont know where to set the eccentric cam in relation to the mark on the shaft. Also the position of the large collar on the left. Is there not a guide for this eg when the cam is all the way pointing to the back? -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Thanks dor the photo advice Garypl Cowboybob. Thanks. I do understand what must happen but im a bit in the dark as to the way to do it considering the settings given by the engineers manual did not result in the needle bar to shuttle relationship beimg right. Should I just experiment until I get it? -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

the settings I changed according to the manual caused the shuttle to not come into timing with needle at all regardless of what I do. so I am a bit lost. I need to have a sequence of what to set first in order to get the whole machine to ideal settings. The eccenrric cam at the back of the machine seems to affect the degree to which the shuttle and needle strokes and cycles function. Any advice is helpful. I am willing to execute technical instructions step by step. My machine is now totally dysfunctional. Eish! -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Thanks Brian. I will do. How do I shrink the size of the pictures. -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Ok. I found that the eccenteic cam at the back of the machine was not set properly ans the top feed cam next to it was not properly tightened. Now I have set it according to rhe juki engineers manual. Now I find needle bar height and hook timing is out. So I will set latter accordingly ans hope for the best. Please share whatever thoughts you have. I follow needle bar height point -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Thanks Brian. I get it now. As Uwe said, those manuals are rather vague. Uwe, my race does not offer the play or give which you show in your video with screws tight or loose. I will post my progress ad I go. Here in SA, technical service is poor at best. Thanks again. -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Brian. Thanks for your input. It seems the distance between the needle bar and throat plate must be 29.5mm once needle has travelled up 5mm? I think we are getting close my shuttle friver touches the needle ever so slightly . -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Thanks again to all for the very helpful replies. I am finding the engineers manual very helpful and Im re setting the machine according to manual. When I set the timing according to book. The needle height is not right. This makes me think the position of the needle bar relative to the drive shaft is off. The reference in the manual doesnt result in the hook to needle height relationship. Will also like to find the reference marks on the shaft of upper feed. Thanks Uwe for your inputs so far. -

CB4500 reverse stitch bottom loops

Zandeosaddles replied to Zandeosaddles's topic in Leather Sewing Machines

Hi Rocky Aussie. Thanks forthe advice, I have the screws on the race one full turm loose. The check spring theory makes sense butI would like to ask if a poorly functioning check spring should affect forward stitch as well? GiGi, my machine is 3 years old and is not nearly worn. Could there maybe be a manufacturing glitch on one of the parts?